Machine vision

Machine vision detection solutions for your projects

Are you looking for a solution based on image processing to control your products? Are you wondering if image analysis would be a suitable solution for your problem? Are you looking for a company to design and build an automated machine, potentially using cameras and vision systems?

Le Sur-Mesure Industriel regularly installs vision-based equipment and systems in its machines to carry out various automated applications. We deal with many inspection topics, based on the most relevant technologies depending on the objectives and performance required of the system: sensor, stand-alone camera, PC-based camera, linear camera.

Image reading for a customized inspection

As part of continuous improvement, equipment modernization, and function automation, our team is also required to address issues of industrial vision, integrated or added to existing equipment. We can also ensure the replacement or upgrade of existing vision equipment or applications on your equipment or production line.

Do you need to test your products to verify the relevance of vision solutions according to your criteria and your reading or detection objectives? Are you looking to automate a check, a foolproofing, a measurement using machine vision technologies by camera?

A project with us: feasibility, a crucial step

Our team from A to Z for the integration of vision solutions

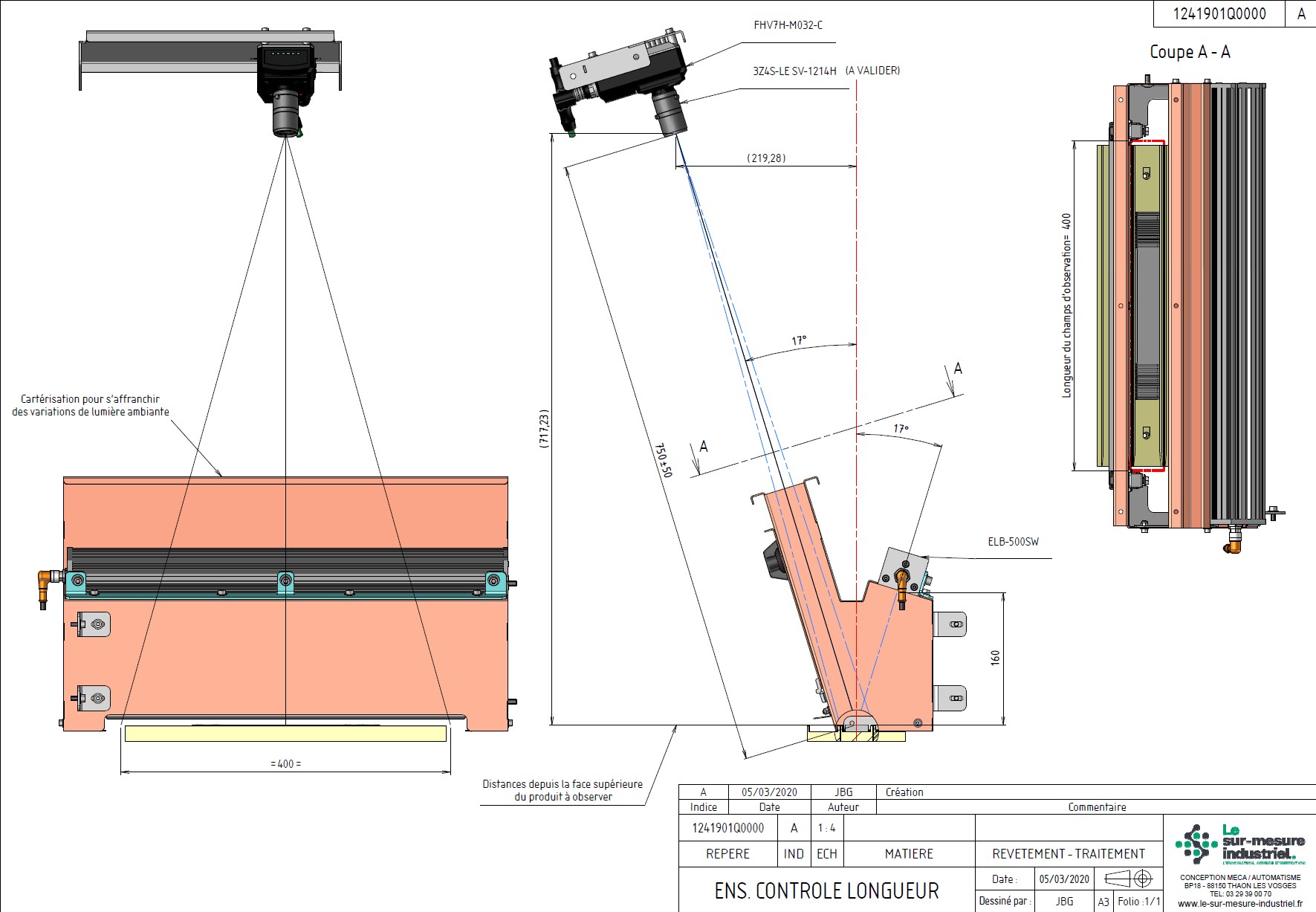

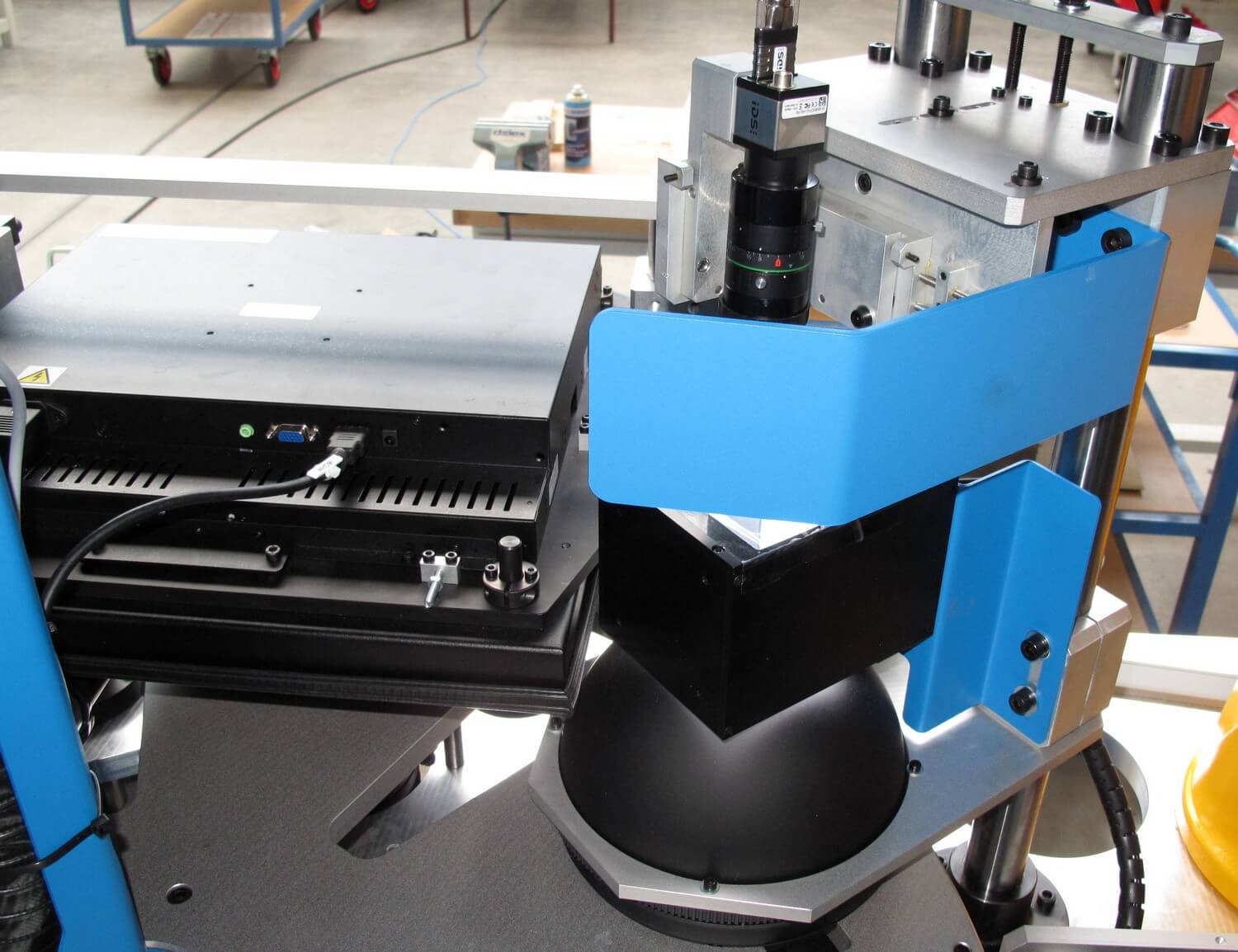

Our multidisciplinary team is at your service to handle your subjects involving machine vision, cameras, lighting from A to Z. We are able to design mechanical assemblies, supports, adjustments, etc. We even sometimes develop specially suitable lighting when commercially available lighting is not suitable. We are therefore free to choose, arrange and orient the LEDs according to the needs of the application. The fixings and cooling of the system are also taken into account during these special developments.

We also handle the electrical integration of components into equipment, then the creation of programs allowing the desired image analyses. Application programming also deals with communication with other interfaced systems: PLC, HMI, user, industrial robotics, PC, database, etc.

Finally, we ensure assembly and development in order to optimize the settings, define all the decision criteria and thresholds, in order to make the analysis result as reliable as possible, while respecting the required quality criteria. Finally, we ensure on-site installation, and training of people, then after-sales service for the maintenance and development of your equipment over the years. Some projects are also handled in direct partnership with the developers at our customers but also in co-contracting with the neighboring company Process Engineering according to the specificities of the application.

The benefits of image processing for automated machines or lines

Among the senses of the human body, sight is very efficient for placing an object, analyzing the characteristics of a product, checking the presence of a component, a shape, a color, the presence of an anomaly, etc.

On the other hand, the industrial context will quickly generate a lot of fatigue, risk of error, monotony if these missions are exclusively entrusted to humans. Machine vision systems aim to perform these operations of processing the information contained in the images by always pushing the limits in terms of rate, reliability, precision, repeatability. This becomes very practical and useful for detecting an anomaly, analyzing a production, improving quality, validating the conformity of products during production for example.

What is machine vision used for?

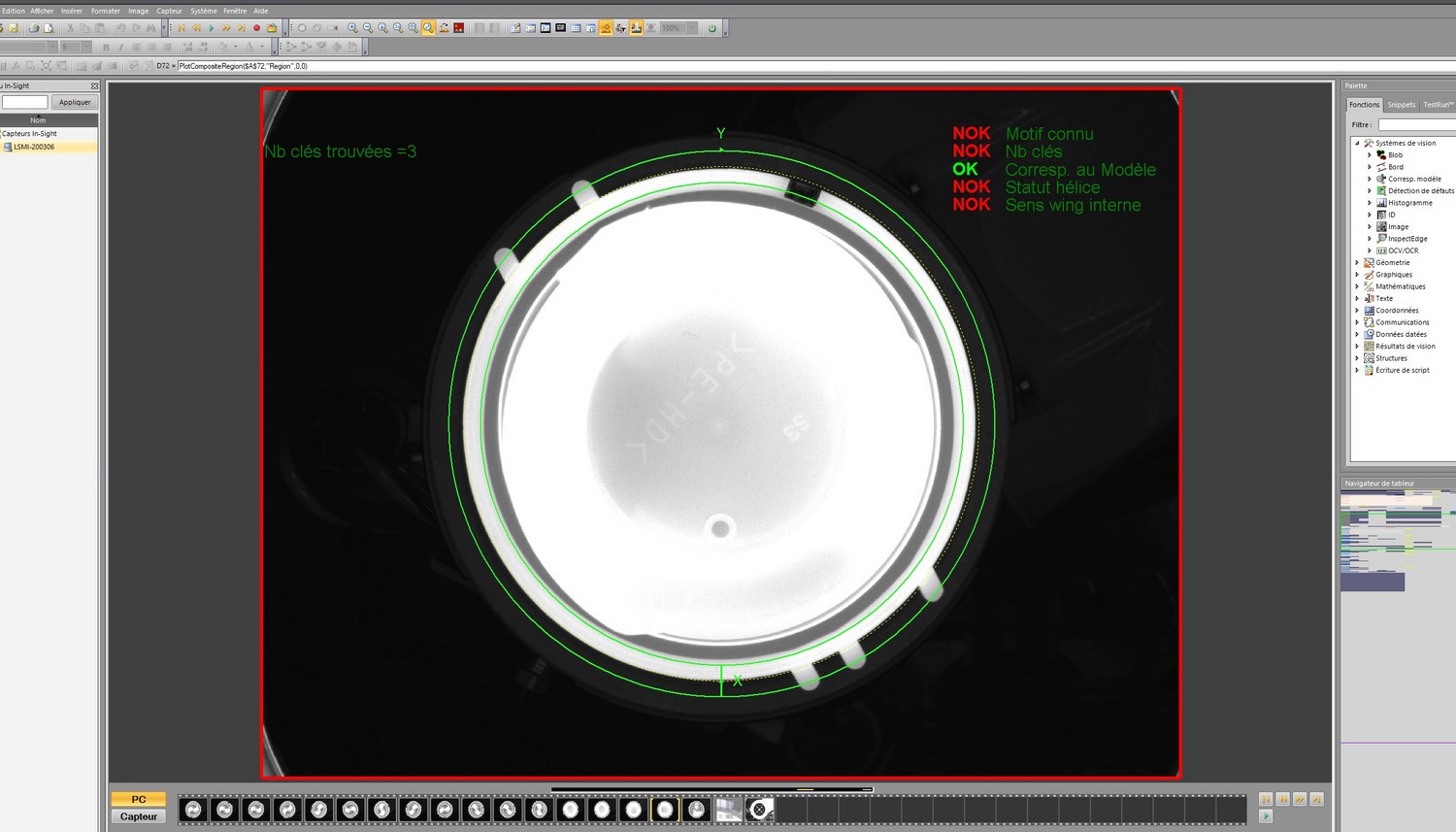

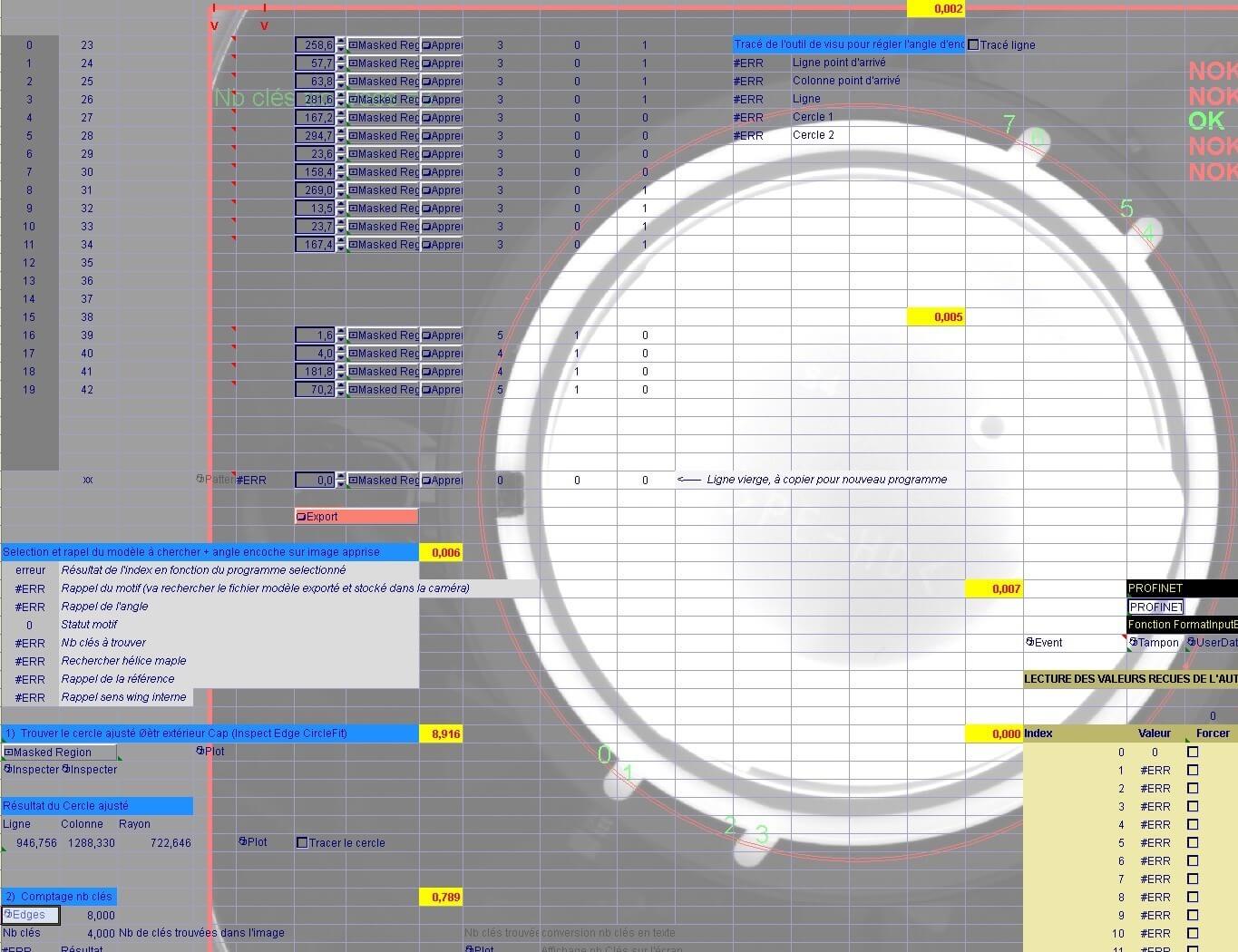

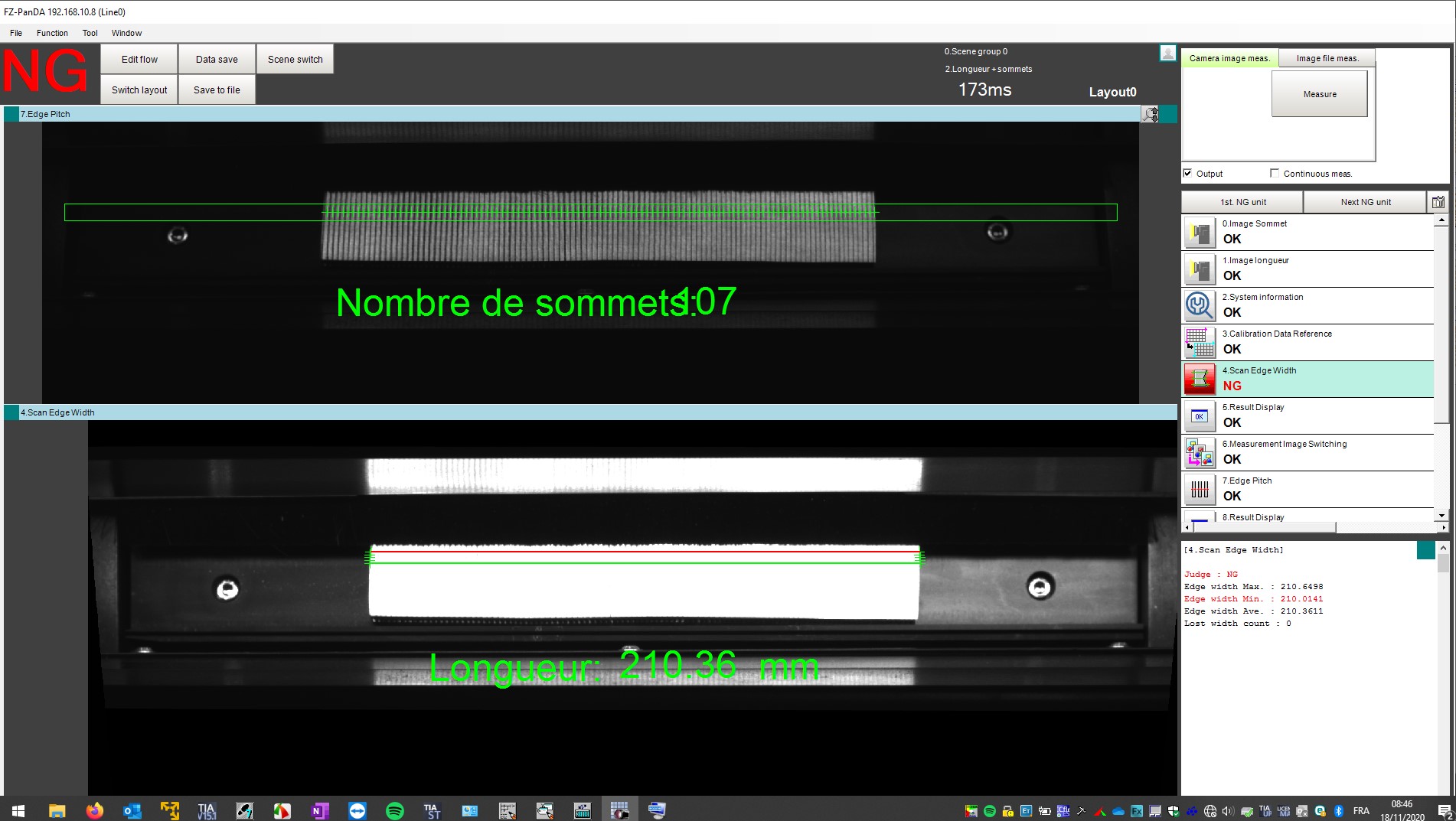

Machine vision uses images to automate the processing and analysis of information to meet a given application. From an image taken by the camera, we create a custom program using different filters and tools to analyze the image and exploit its content.

The application may consist of an analysis of the presence, integrity, position, orientation, shape of a component. Depending on your activity, your products, your quality objectives, it may be useful to measure a characteristic, count, recognize, correct, etc. Many applications also require text reading, code reading (1D, 2D, QR code). The criteria can be numerous and the applications in the industry very varied: production, quality, assembly, robotics, etc.

Also see other examples of measurement and control applications.