Assembly and production

Production and assembly of your parts

- Is your business growing and are you looking to automate certain manufacturing, control, assembly or packaging operations within your factory?

- Are you developing a new product and looking for the equipment that will enable its manufacture and assembly?

- Do you want to replace an existing assembly line or add a new one to your workshop?

Le Sur-Mesure Industriel is your contact of choice in the Grand-Est to support you in all your projects for the study and production of machines and assembly lines for industry.

Who are we ?

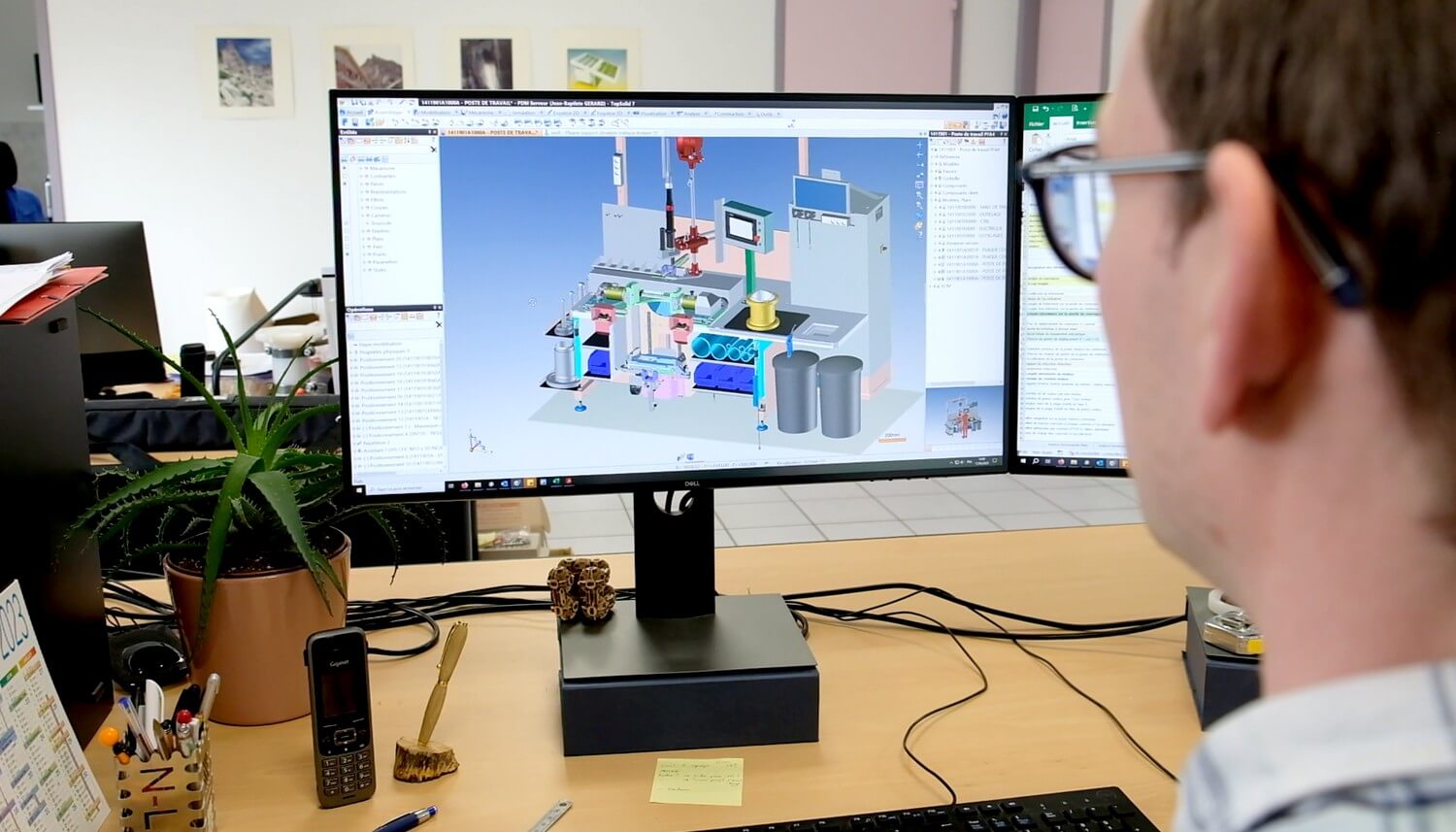

We are a design office, located in the Vosges, in the heart of the North-East quarter of France. Our company offers custom-made equipment development services for all manufacturers in the Grand-Est, Alsace, France and also abroad.

We bring a neutral perspective to your issues and propose the most effective concepts to meet your manufacturing needs. We adapt the best technologies to match your specificities and your products.

Our industrial expertise at the service of your processes

It is sometimes difficult to choose the right machine concept, or the right technologies depending on the applications. We are experienced in researching and selecting or creating technical solutions that will meet your problem.

As a design office and designer of special machines, our company has a strong base of skills in mechanical design, assembly and industrial automation. This gives us the internal flexibility and agility to produce all-in-one industrial machines, perfectly adapted to your needs.

We implement all of our skills to develop your complete manufacturing line, or to integrate functions into an existing system, for example.

We guarantee the supply of suitable processes and technologies for our industrial customers, supporting them through all stages: definition, design, automation, robotization, installation.

Setting up an assembly line for your products

Depending on your application, we analyse which concept best matches your specifications:

- Loading and unloading station for components and finished products (manual or automated)

- Inline assembly equipment (semi-continuous process)

- Integration of any assembly principle (welding, screwing, fitting, gluing, riveting, etc.)

- Equipment with or without integrated control, for compliance, quality

- Monitoring, traceability, communication with the supervision system

- Safety with two-hand control, light curtain, doors, grilles, etc.

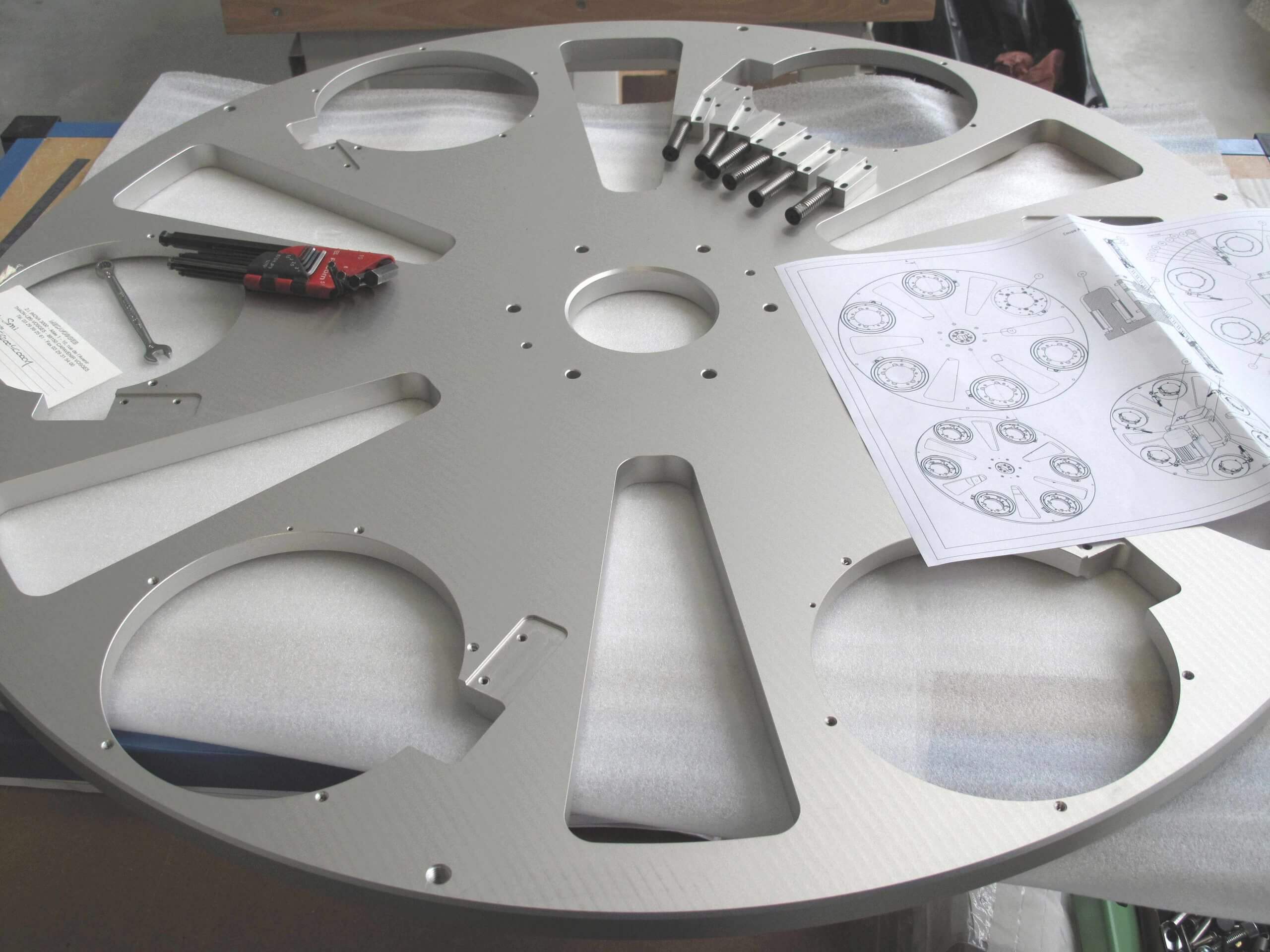

- Turntable plate machine

- Step-by-step conveyor, accumulation

- Pallet racetrack

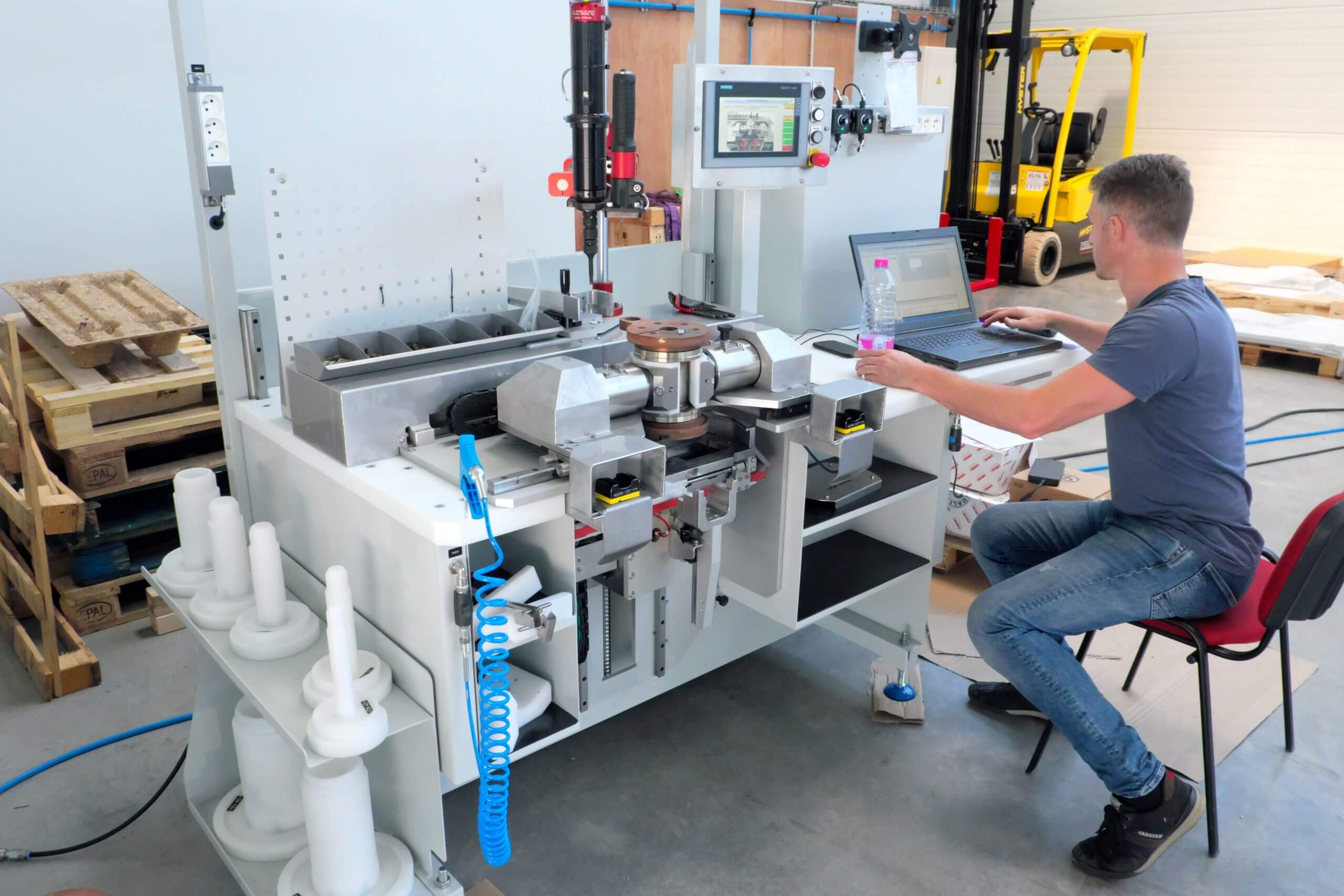

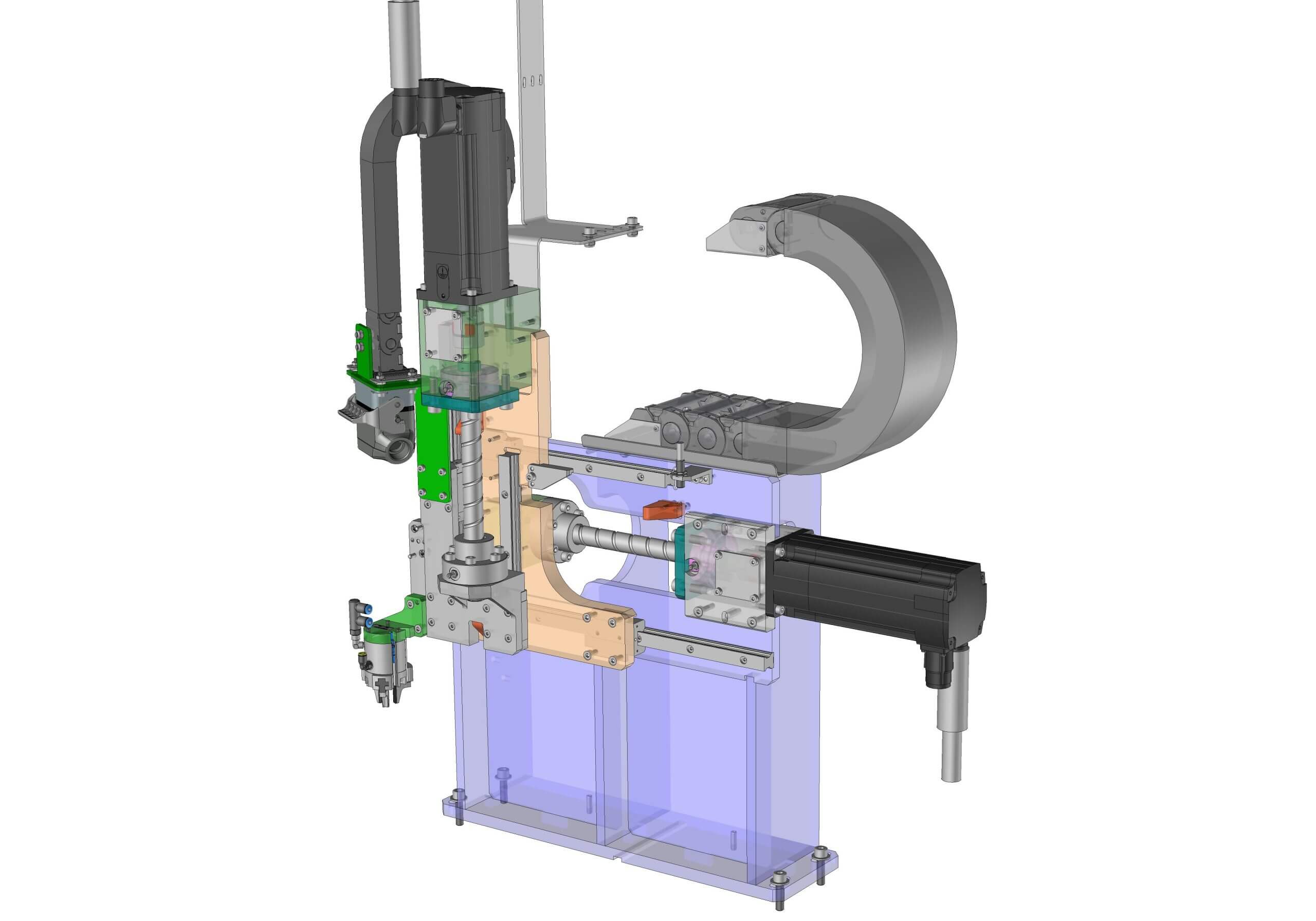

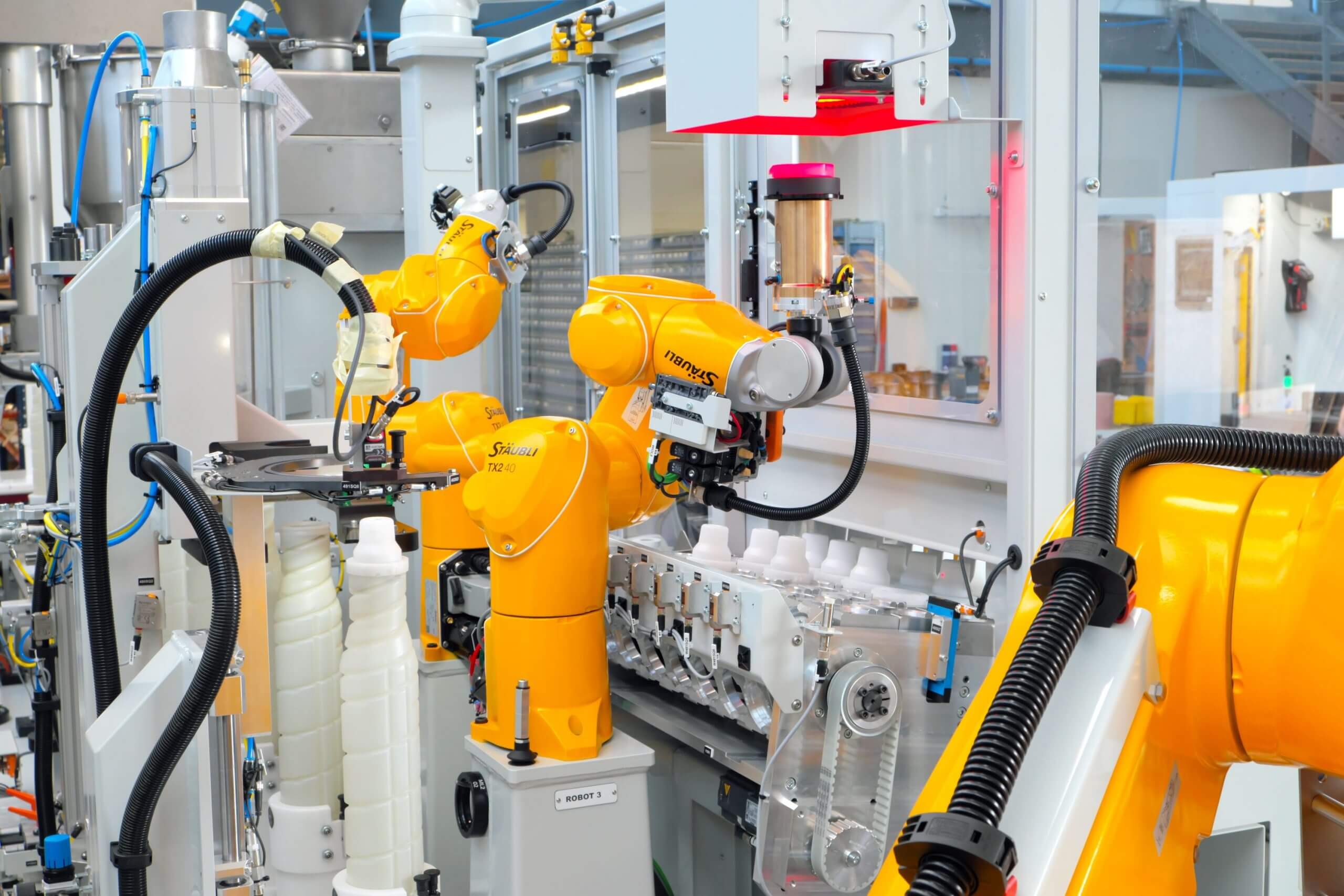

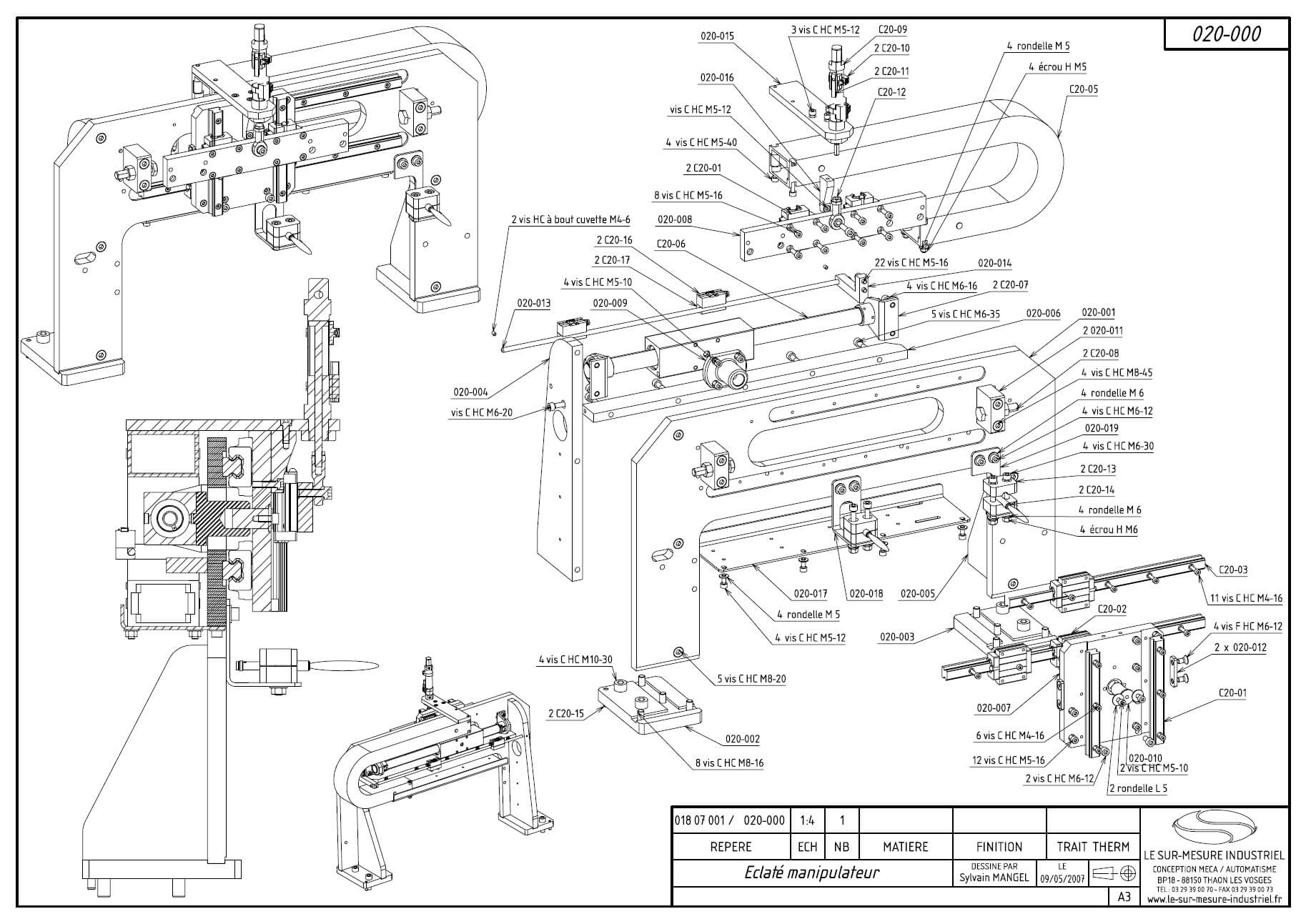

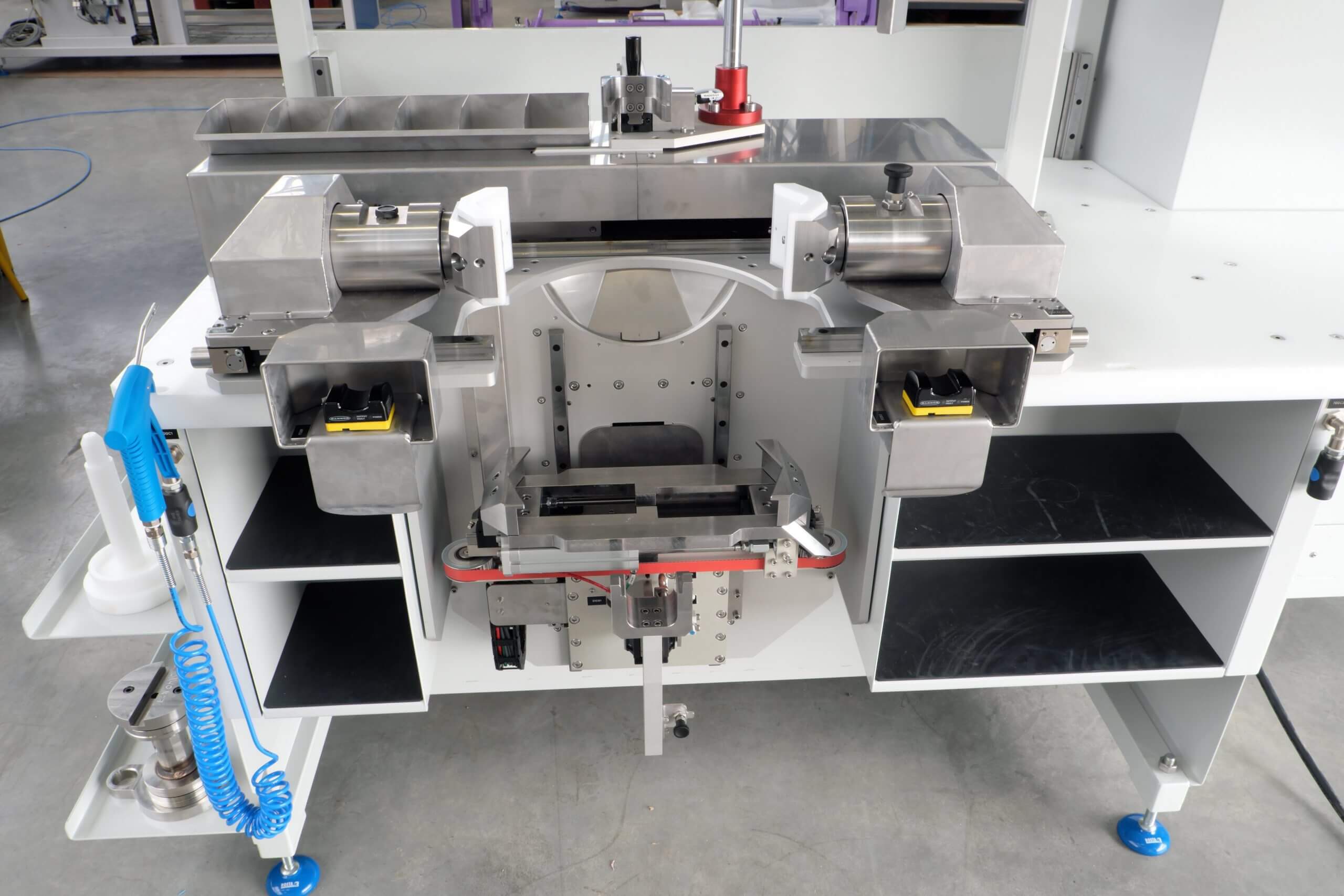

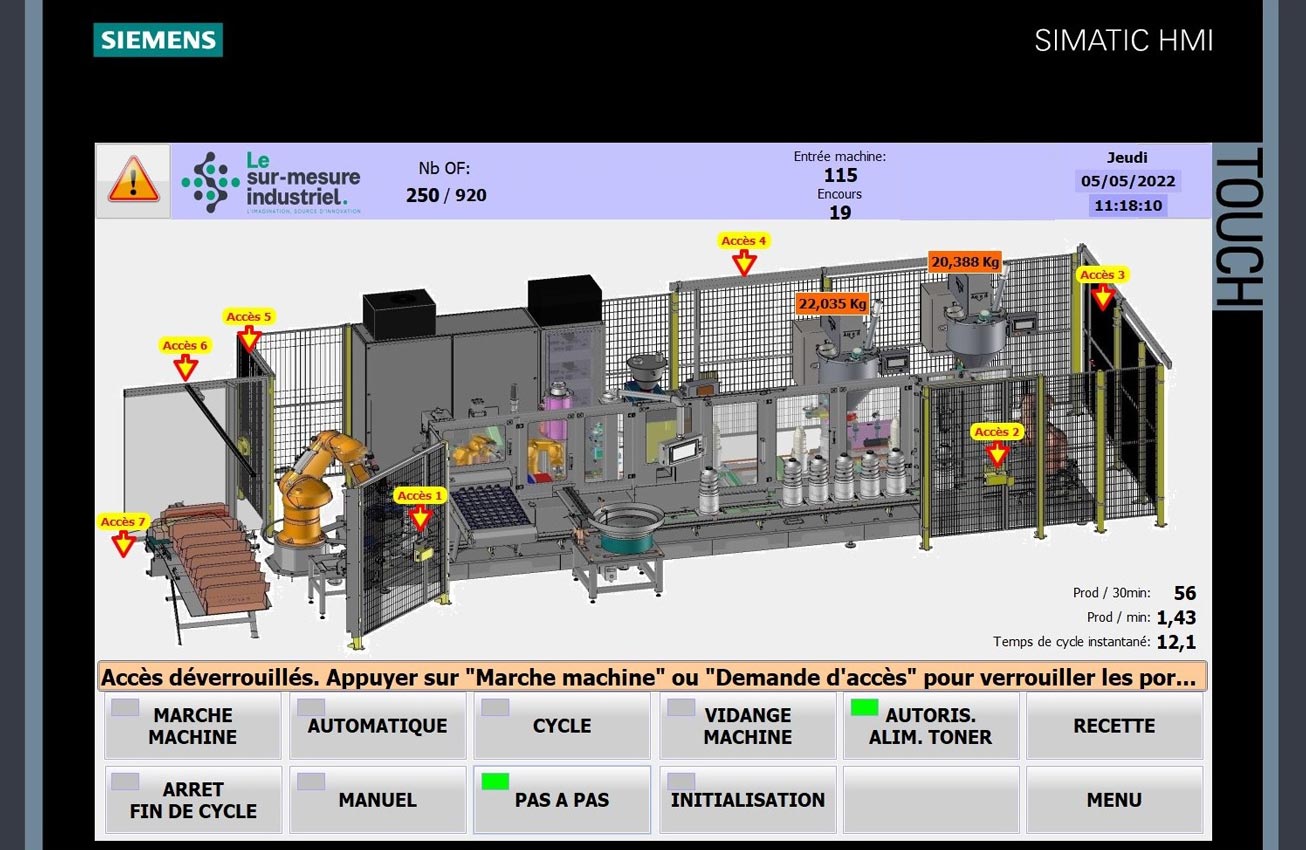

In pictures:

Example of production on a carousel machine:

In line with your products, here are some examples that can be offered:

- Parts loading station, manual or automatic (component feeding by hoppers, vibrating bowls, separators, robot, etc.)

- Workstation(s) on components (positioning, welding, crimping, screwing, riveting, gluing, etc.)

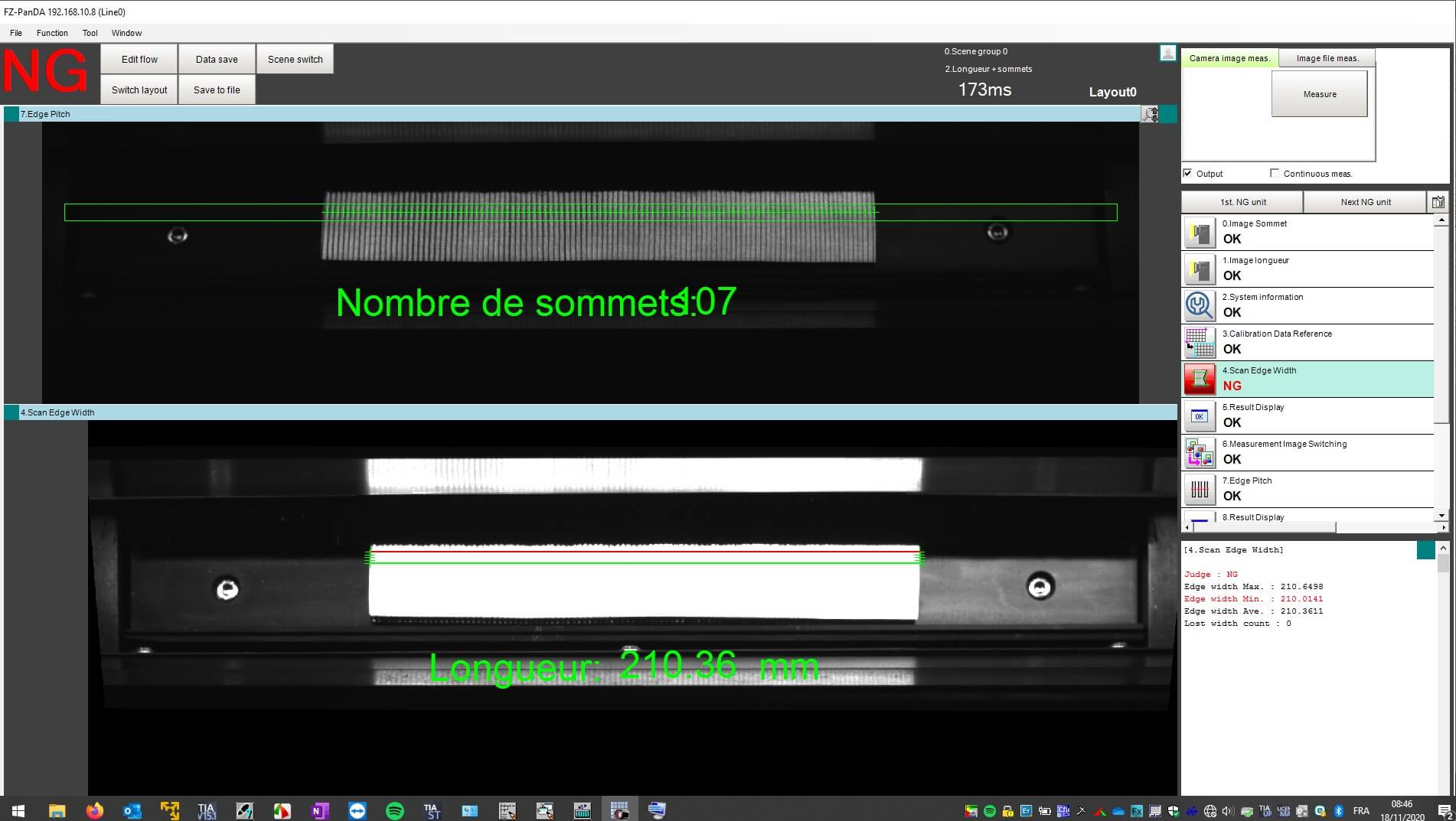

- Inspection station(s) on parts: (vision, measurement, leak test, continuity, etc.)

- Packaging stations (grouping, bagging, boxing, etc.)

- Manual or automatic unloading station

- Connections with downstream machines or packaging and wrapping station for example.

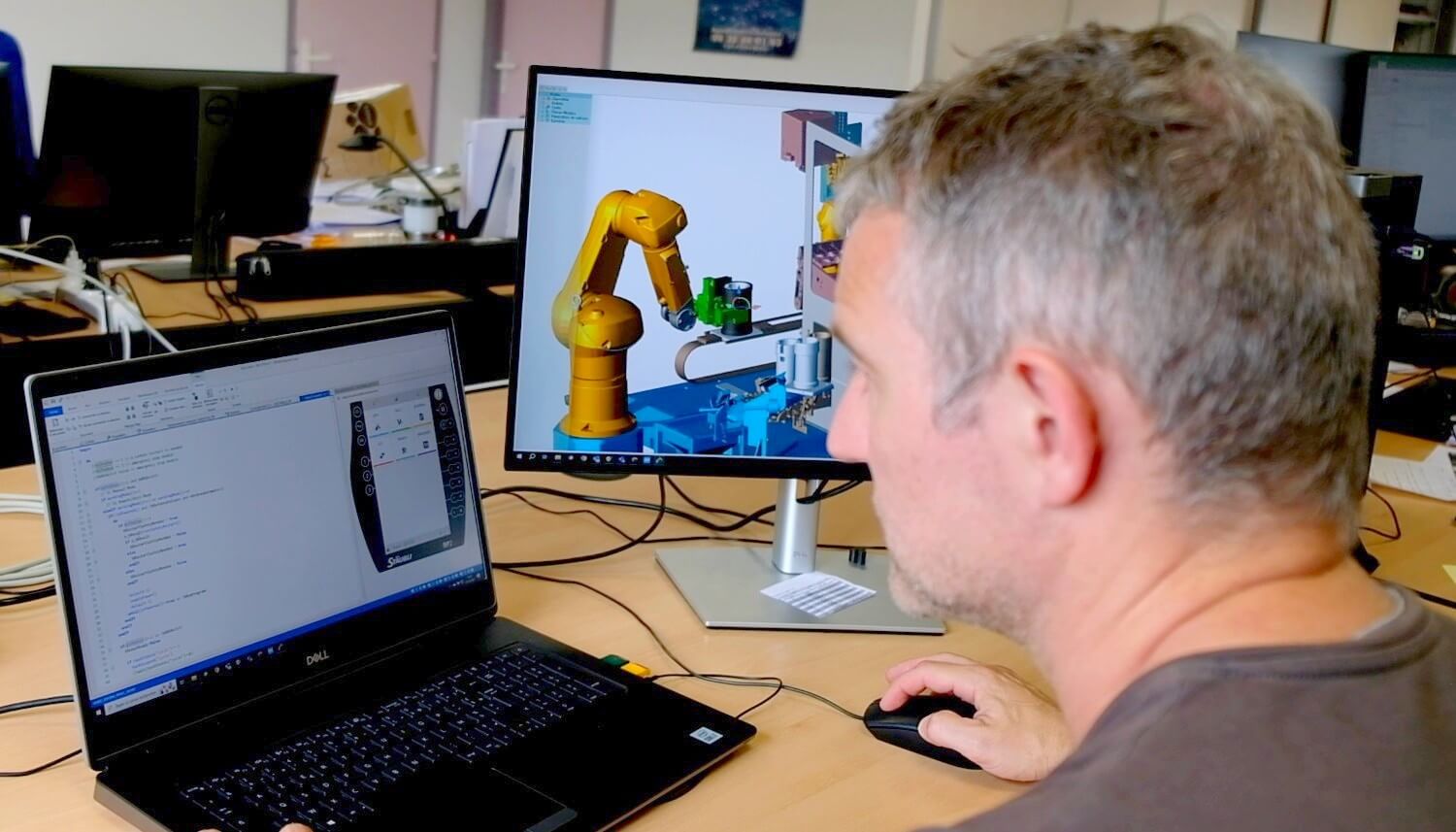

Versatile integrator: Mechanics, Automation and Robotisation

At Le Sur-Mesure Industriel, the team at your service has all of these skills!

This represents a major advantage in terms of communication, efficiency and simplicity for our customers. Indeed, for the supply of an automated or robotised chain, it is very practical and efficient to have a permanent link between the mechanic, the automation engineer and the robotics engineer within the same company. The interface between all these disciplines is optimal during the design, and until commissioning in your factory.

Online quality checks

Are you looking to make your machines or industrial assembly line more reliable? Would you like to improve the quality and consistency of your manufacturing or assembly processes?

It is essential to equip yourself with machines and lines using technologies that allow you to control the important characteristics of your parts and products, in order to guarantee optimum quality.

Detecting an anomaly as early as possible during the process on the production line is often essential. In order to avoid chaining operations on a product that will ultimately be scrapped, proper control allows the part concerned to be immediately removed, or even its components recycled.

To enable the measurement of the appropriate quantities, we define the appropriate system, device, sensors, and detection principles, taking into account the product characteristics you want to monitor. We also set the levels and thresholds beyond which an alert or alarm is generated. This allows the operator to react quickly and appropriately to restore proper operation.

See also our “Measurement and controls”

Production line 4.0

The equipment we supply collects, displays and communicates production information: operating status, rate, reject rate, counters, defects, etc. When designing our machines, we also very frequently integrate control equipment and systems to monitor important characteristics of the product being processed. It is very important to judiciously select the parameters monitored according to the desired objectives.

For example, the acquisition of these measured data makes it possible to collect very useful information to analyse the operation and performance of equipment. This can also make it possible to understand phenomena, analyse drifts, perform diagnostics, and define corrective actions, with the aim of fully controlling the operation. The analysed data also makes it possible to automate adjustments or compensations to meet ever-increasing needs for cadence, quality, and regularity.

The exploitation and analysis of production data can be carried out directly on the line, but very often require connections with other remote systems and equipment. For assistance and after-sales service, the connectivity of the equipment we develop also represents a huge advantage. Responsiveness is maximum for troubleshooting or remote diagnosis when possible.

We will establish with you how the information collected should be presented, stored, transmitted to other systems, etc.

Intuitive machine control

The Human Machine Interface or HMI is the means of controlling the machine. It also allows the equipment to communicate any useful information to its user.

Our automation engineers pay great attention to developing reliable programming and neat and sophisticated HMI interfaces so that machine operation is as clear and intuitive as possible.

The screens show all the information and detailed messages on the operating status, parameters and fault identification for example. This is very useful to facilitate the operation and maintenance of the equipment we supply. The different users or maintenance personnel become very autonomous very quickly.

Frequently Asked Questions About Assembly Machines or Production Lines

How much does a custom production machine cost?

What is the average time for studying and manufacturing a production line?

What is the maximum project size for your company?

On the other hand, we deal daily with the study and manufacture of machines, or medium-sized lines for the production and assembly of various products.