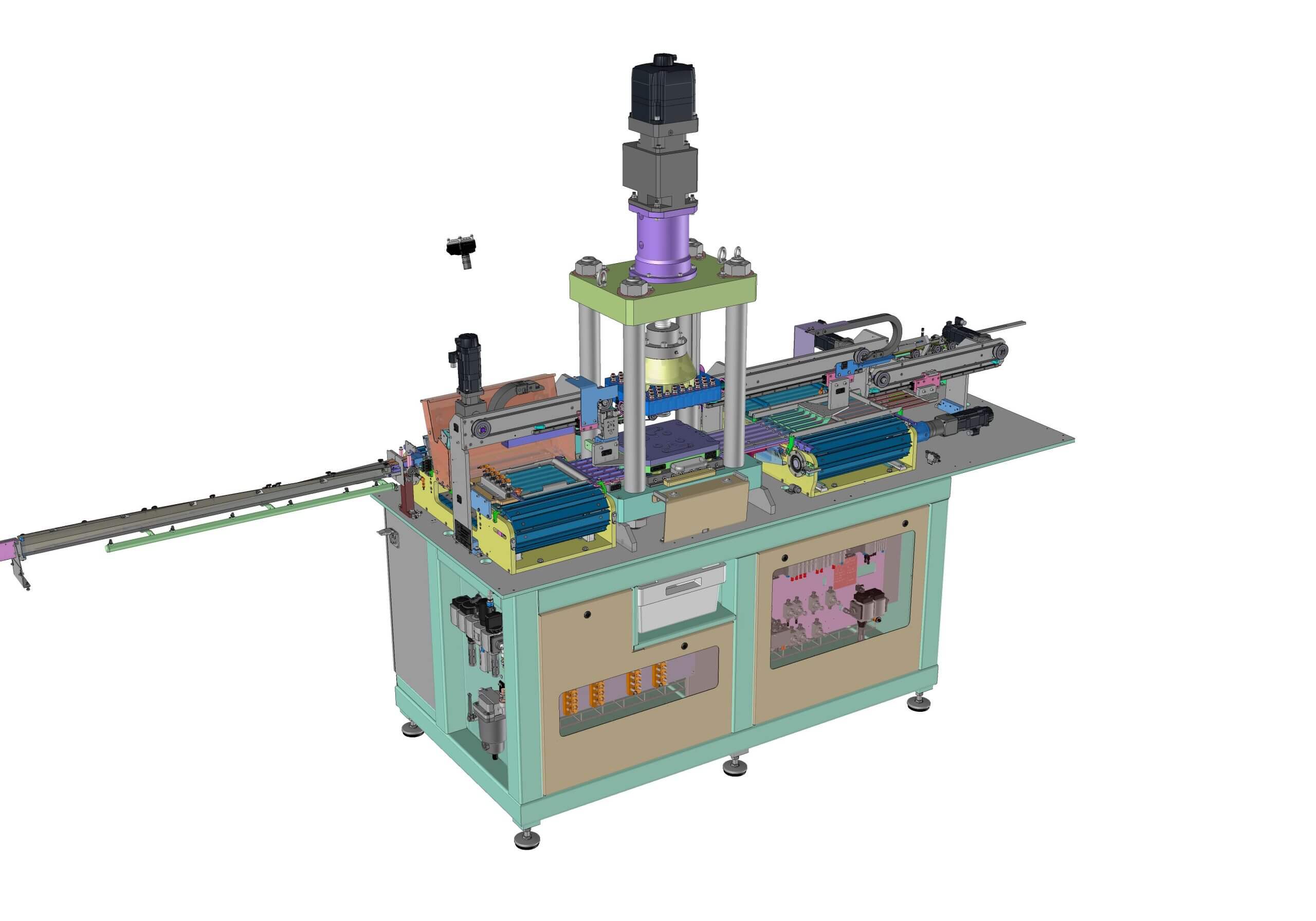

Transformation / Cutting / Machining

Industrial cutting machine

- Do you work with wood, paper, plastic or any other material and want to add a new function to existing equipment?

- Do you want to upgrade or update your equipment using current technologies?

- Do you need to replace an industrial machine, or supply new industrial equipment in the broad sense?

Le Sur-Mesure Industriel develops turnkey, custom-made solutions, adapted to your needs and your products. We are designers and suppliers of machines and equipment, serving industrialists in the wood, paper and plastic processing industries in particular. Browse the examples below to get an overview of several achievements in the wood, paper and plastic processing industries.

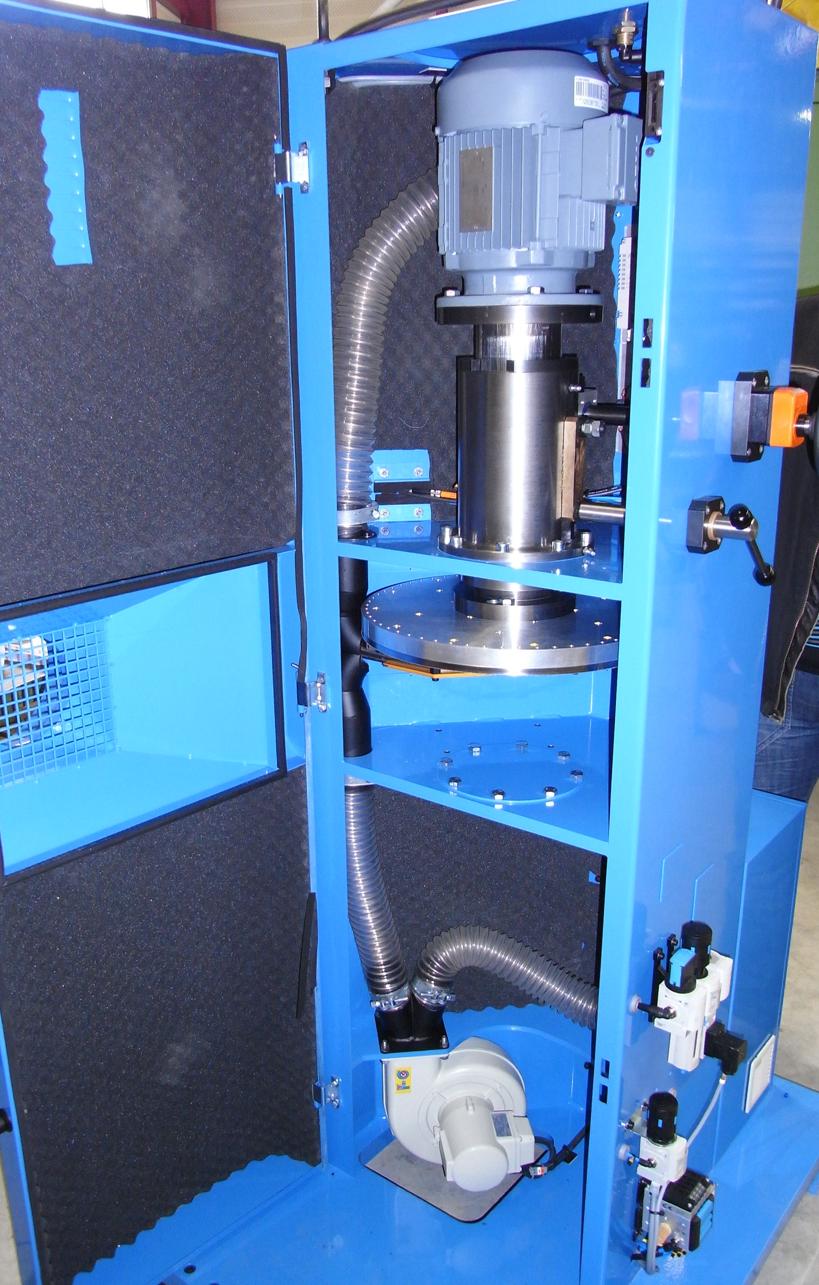

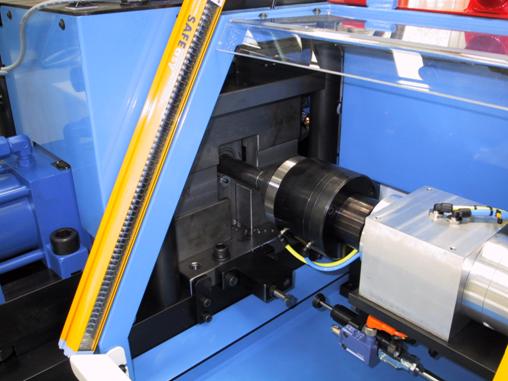

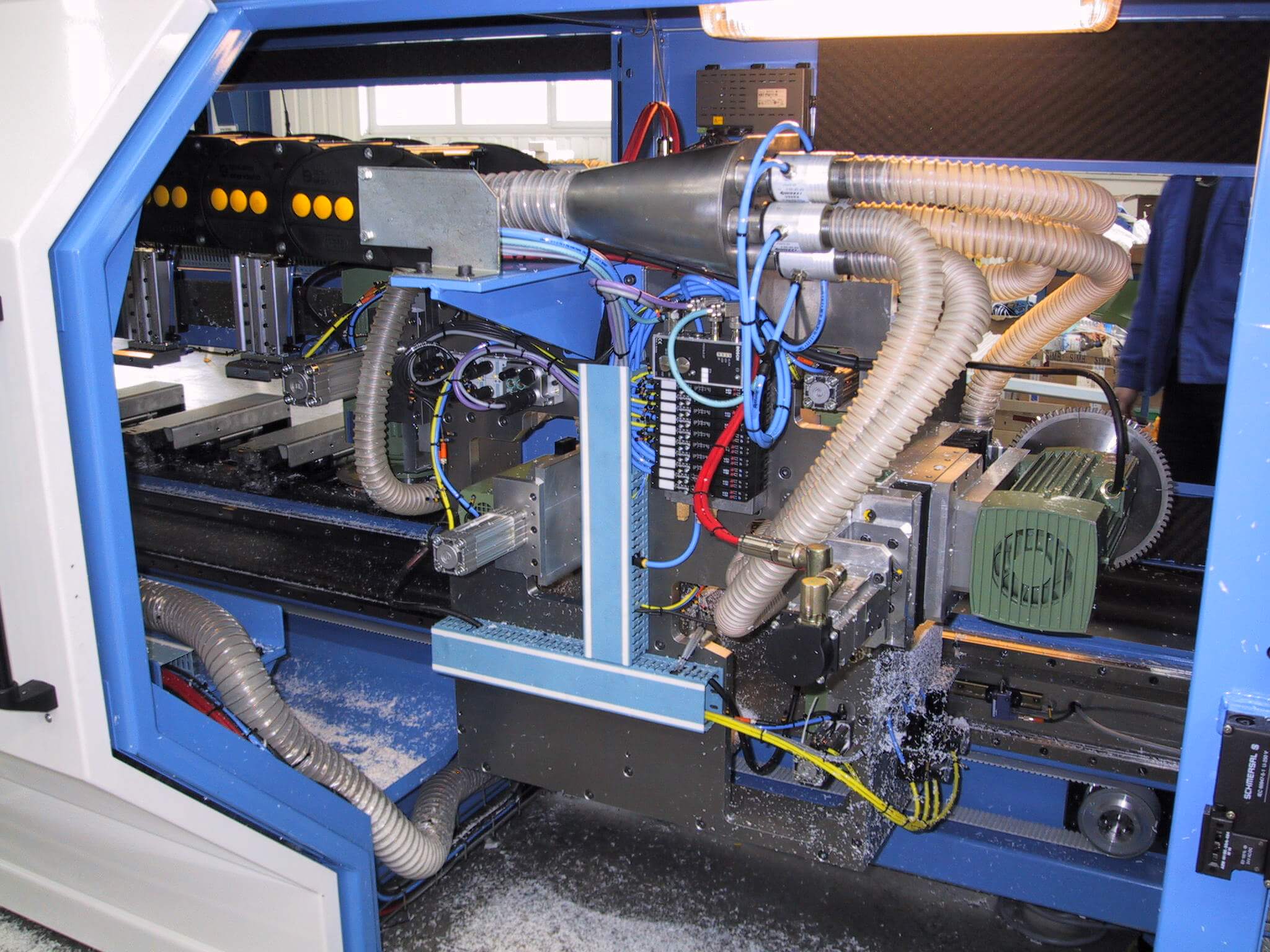

- Machining of window frames for industrial joinery (5 machining spindles – 3 servo motors – Choice of machining by function blocks – High-speed suction

- Spring grinding

- Gantry for grooving aluminum profiles

- Multi-blade machine for the wood packaging industry

- Cutting and bending of metal wire

- Shaping of metal fabric (cutting, assembly, welding, shaping)

- Compression of metal lamellae

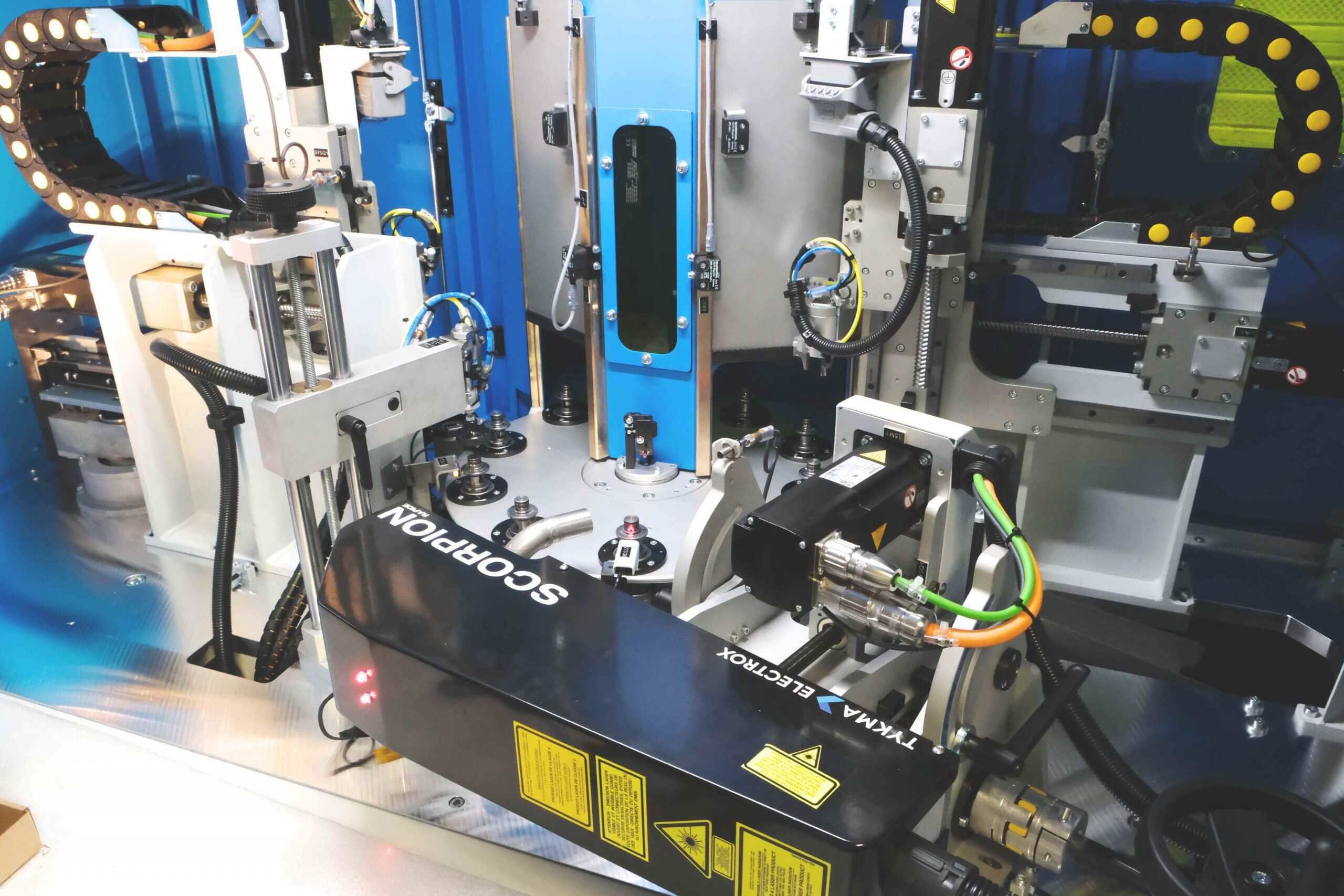

- Automatic laser marking

- Molds and cam kinematics for wood fiber pots

- Water jet cutting

- Guillotines

Creation or development of your equipment and machines

Le Sur-mesure Industriel, situé en France, dans les Vosges, est votre partenaire et fournisseur idéal dans le Grand Est pour la création ou la transformation de vos équipements de découpe.

Avec notre professionnalisme et notre expertise, nous nous adaptons rapidement à des sujets et contextes industriels très variés. En fonction de la situation et de vos besoins et produits, notre volonté est de toujours apporter le service adéquat. Nous traitons de nombreux sujets partant de l’idée, du besoin, et passant par les étapes de conception et réalisation, jusqu’à la mise en service et le SAV.

Si vous cherchez un fournisseur pour faire évoluer ou créer une machine industrielle, nous pouvons tout à fait vous accompagner grâce à nos prestations d’ingénierie industrielle.

Feasibility and process study

Some problems may require a feasibility study. This is a starting point that allows you to test an idea, a concept, in order to validate that the proposal will be adapted to your products and will meet the need.

For example, depending on the materials to be cut, different techniques can be considered and compared. Once the process has been determined, the study and production of the entire equipment is possible.

The total duration of a project varies, depending in particular on its complexity. Some developments can represent a few weeks for a small manual cutting tool. Other larger projects require several months or years to cover the stages of design, production, programming and commissioning of complex machines, or even automated production lines around laser, plasma or water jet cutting machines.

Your new “custom-made” cutting machine

Une machine industrielle de découpe « sur-mesure » est un équipement conçu spécialement pour découper ou transformer un produit donné. Il y a une grosse différence avec un équipement dit «standard». En effet, une machine spéciale pour découper différents matériaux est développée et fabriquée sur-mesure, pour répondre à votre besoin.

Cela peut être une scie, une cisaille, un massicot, une machine de découpe par jet d’eau ou laser, mais toujours adaptée spécialement à vos produits, en tenant compte de toutes les contraintes spécifiques à votre activité, à votre application, aux matériaux à travailler.

Si vous êtes à la recherche d’un tel équipement, ou que vous souhaitez un développement, une conception, spécifiquement adapté à vos besoins, vous pouvez faire appel à nous. Le Sur-mesure Industriel, basé dans les Vosges, vous accompagne dans le Grand-Est, sur toute la France et même à l’étranger. Notre bureau d’études est votre interlocuteur unique pour traiter de A à Z votre projet de machine industrielle, de la conception jusqu’à la mise en service.

Automation of cutting lines

Are you equipped with laser, plasma or waterjet cutting machines, machining centers or a saw, and you want to automate the handling upstream and downstream of this equipment? Do you need to increase your productivity by automating certain repetitive tasks?

Do you want to relieve your employees by mechanizing certain arduous tasks around laser, waterjet, plasma systems?

We are able to support you in these different projects to study and provide custom-made equipment that meets your needs:*

- Conveyors

- Manipulator, gripper, robotization

- Parts control and sorting

- Marking

- Packaging

But also: fitted workstation, handling tools, tools to facilitate maintenance or adjustments.

Waterjet, laser, plasma cutting

In our recent projects, here is an example of automation of a cutting operation on a continuous production line: Initially, the operation was manual and tedious using a cutting blade.

To automate the function, make it more repeatable, more reliable, we tested, developed and commissioned a configurable high-pressure water jet cutting system. This fully custom-designed equipment specifically meets the needs and production of our client by adapting an existing water jet cutting technology.

From this example, we could quite imagine and design customized installations of systems using other cutting techniques based on laser, plasma, machining for example. It all depends on the materials and products to be worked and cut, as well as the specificities of the application.

Frequently Asked Questions About a Cutting Machine

What process should be used for cutting metal or steel?

There are many possible processes for cutting a metal such as steel: laser cutting, oxycutting, water jet cutting, shearing, sawing, machining, etc. The choice is made according to different criteria: mechanical characteristics of the metal used as raw material, dimensions, thicknesses, shapes to be produced, expected finish and precision, etc.

How accurate is a laser cutting machine?

Current laser cutting machines achieve precision levels of less than a tenth of a millimeter. We use this process very frequently for the manufacture of our steel sheet metal parts. Laser cutting allows us to obtain very good precision for our machine covers and cladding, for example. We produce these mainly in mechanically welded and painted steel.

How much does a custom metal cutting machine cost?

It is not possible to answer this question directly. Indeed, to define the budget of a machine, it is necessary to define its characteristics, its capacities, its functionalities, its objectives, etc. The specifications are a document that allows you to list and define all these aspects at the start of the project. We can fully support our customers in defining their specifications for a machine. Then, technical solutions can be considered and costed.