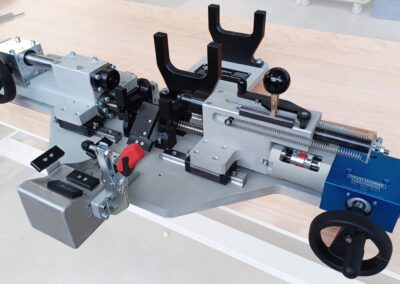

Design and assembly of special machines and equipment for industry

Here are some interesting examples, chosen to show you the results of several of our studies and realizations of special machines. Click on a project to learn more.

How does the acquisition of a special SMI machine take place?

Study and design

After collecting the very important information concerning the precise need of our client, its context, its products, we propose innovative concepts to respond to the problem. We can be a force for proposal when the solution is not obvious and very often assist our clients in the very definition of the technical characteristics and limits of the equipment to be designed. Then, our mechanical design office ensures the detailed 3D CAD design of the future machine by creating and assembling on computer all the components necessary for its operation. In close collaboration, our automation engineers ensure the electrical and pneumatic study with the definition and selection of the necessary materials and the production of diagrams and nomenclatures. Of course, the notions of ergonomics and safety are at the heart of this design stage and throughout the project to result in a practical, functional, efficient and pleasant machine to use in complete safety.

Next come the stages of manufacturing, assembly and development of the equipment.

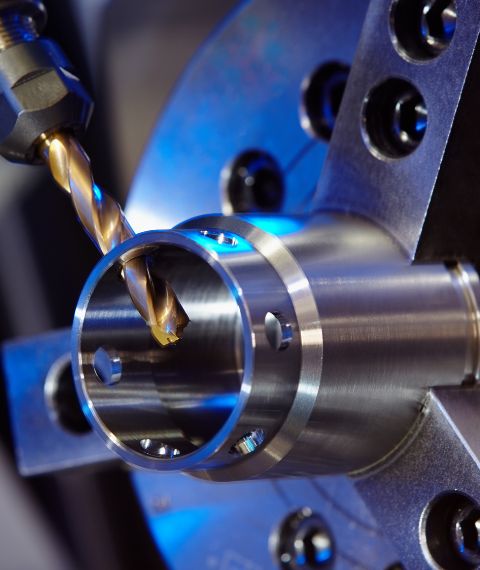

We rely on our varied panel of suppliers to produce the parts we design: precision machining, electrical discharge machining, sheet metal working, mechanical welding, molding, or any other process depending on our needs.

Depending on the technical characteristics and expected functionalities of the manufactured parts, we carefully select the materials, coatings and heat treatments as well as the geometric and dimensional tolerances. All this information appears on the detailed manufacturing drawings, produced at the end of our mechanical study.

At the same time, we supply the commercial components determined during the mechanical and electro engineering studies from the best manufacturers.

When all the spare parts are received, we assemble the machines ourselves in the assembly hall attached to the design office. This important step allows us to validate all the assembly operations.

Next comes the electrical wiring and programming of automated or robotic functions. These missions are carried out by our automation engineers. This is when all the movements, their sequences and all the operating modes are put into service, tested, refined, optimized, validated with our customers during a reception at our premises.

Installation, on-site commissioning, support

Finally, we intervene on site, in factories and workshops to install and commission the machines. On this occasion, we set up the machine and reassemble it. We finalize the tests and adjustments in real production conditions, and we provide training to the people concerned in the production, maintenance, quality services teams, etc.

And after?

To ensure easy operation and maintenance of the machines we supply, we pay particular attention to developing reliable mechanics and programming, as well as neat and sophisticated HMI interfaces so that the use of the machine is as clear and intuitive as possible. This includes detailed information and messages on the operating status, parameters and fault identification, very useful for the various users or maintenance personnel who quickly become autonomous.

In addition, our customers benefit from the complete technical file. It includes all documents such as the user manual, the list of recommended spare parts, preventive maintenance operations, exhaustive parts and component nomenclatures, assembly and exploded drawings, electrical and fluid diagrams, CAD files and source programs.

We are also happy to respond to any request for support or assistance following commissioning, for all our equipment in operation for 32 years, in France or abroad!

Our philosophy for creating machines

Since its creation, Le Sur-mesure Industriel has been building equipment for industry, in accordance with the rules of the art and in compliance with applicable standards. As a manufacturer, we conduct risk analyses and CE certify our machines.

We are committed to satisfying our customers by providing reliable, robust, well-sized, high-performance machines. To achieve this, our studies include all the calculations, sizing, cycle time, resistance, necessary for the application.

Throughout the machine design process, we prioritize good ergonomics for the end user. Our automation engineers develop sophisticated interfaces for viewing information and controlling equipment. We always seek to provide good visibility of the process and good accessibility to settings and products with practical access and openings in the casing. We respect the recommendations of ergonomists for defining work areas, heights, manual efforts and handling that may be necessary.

What is a special machine?

A special machine is a machine or equipment designed specifically for a given need or application. The difference with so-called “standard” equipment is major. Indeed, a special machine is a custom-made machine developed and manufactured to satisfy your need, according to your products, taking into account all the constraints specific to your activity and your application.

This can concern any industrial process: production, manufacturing, transformation, assembly, handling, control, packaging, marking, etc.

Some topics may require feasibility. This is a preliminary step that allows you to test a concept, an idea, in order to validate that the proposal will meet the need explained before considering the equipment in its entirety.

The total duration of a project varies, depending in particular on its complexity. Some developments can take a few weeks for a small handling tool, for example. Other, more substantial projects require several months or years to cover the stages of design, production, programming and commissioning of complex machines, or even complete production or assembly lines.

If you are looking for such equipment, or if you want a development, a design, specifically adapted to your needs, you can call on us. With its experience in many fields of activity, mainly in industry, Le Sur-mesure Industriel, based in the Vosges, supports you in the Grand-Est, throughout France and even abroad.

You benefit from a single point of contact who handles your special machine project from A to Z, from design to commissioning.

In any sector of industry, are you facing a problem in your production workshop? Do you have a new need? Are your products evolving? Are you looking for a machine, a means of control, custom-made tools? Contact us to tell us about your project and study together the possibilities of a collaboration.