Commissioning of a machine in China and training

No vacation, but a trip to China!

At the end of August 2024, a member of our team went to China to our customer’s factory to carry out a week of training and continue the development of our automated assembly machine. This is a good example of our ability to manage and successfully complete a project abroad.

The design and production of this industrial assembly equipment took just under a year. The machine was delivered in 2022, but no travel was possible at that time due to Covid.

Always in contact with our client since the delivery of their custom-made equipment in order to ensure with them the commissioning, a trip to the site proved relevant this year to continue training the various users and better transmit knowledge and technical information.

This on-site meeting allowed our client and its teams to benefit from a transmission of information on the operation, adjustment, configuration, maintenance of this complex production machine.

The effectiveness of live exchange on the production site is once again confirmed because it has enabled significant improvements in production quality, better control of the equipment and greater autonomy for our client.

Information about our industrial production machine

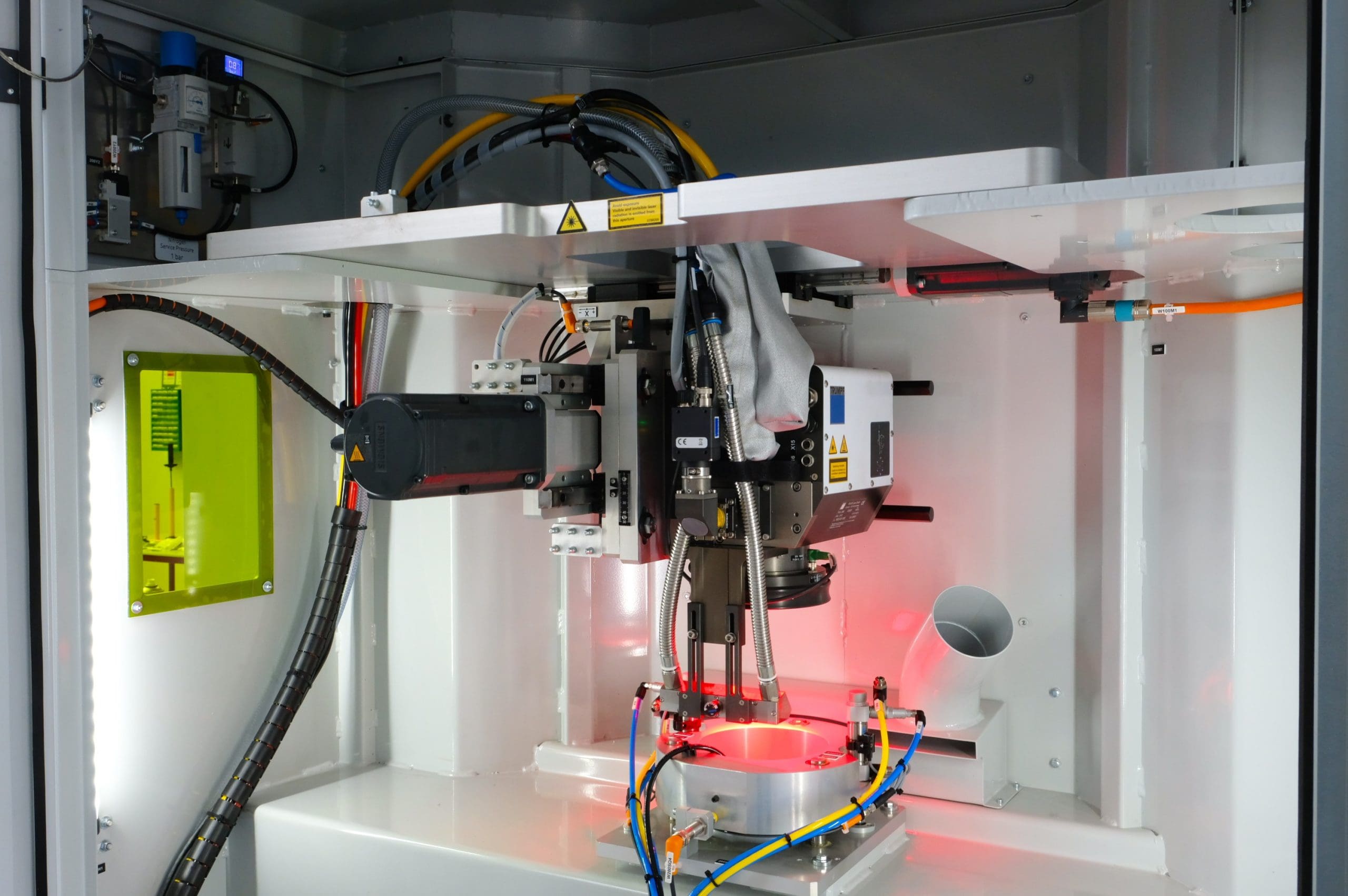

This assembly machine allows manual loading of parts, then riveting and automatic laser welding of components. The hardware and software architecture integrates different complex technologies:

- Machine vision for component detection and control

- Riveting and instrumentation (force monitoring, travel)

- Component positioning and measurement integrated into tools

- Laser welding with movement on X and Y servo motors

- Automation and HMI