Food-industry

Our philosophy for creating a machine for the food-industry sector

Le Sur-Mesure Industriel has always aimed to satisfy its various customers by providing well-sized, robust, reliable and high-performance machines. This is particularly important in the food industry where equipment very often produces continuously and requires high availability.

To achieve this, our studies include all the steps necessary for the success of the application. Feasibility, calculations, sizing, cycle time study, design and detailed schematic.

We build equipment for many industries. We work in accordance with the rules of the art and in compliance with applicable standards. We conduct risk analyses and our machines are CE certified.

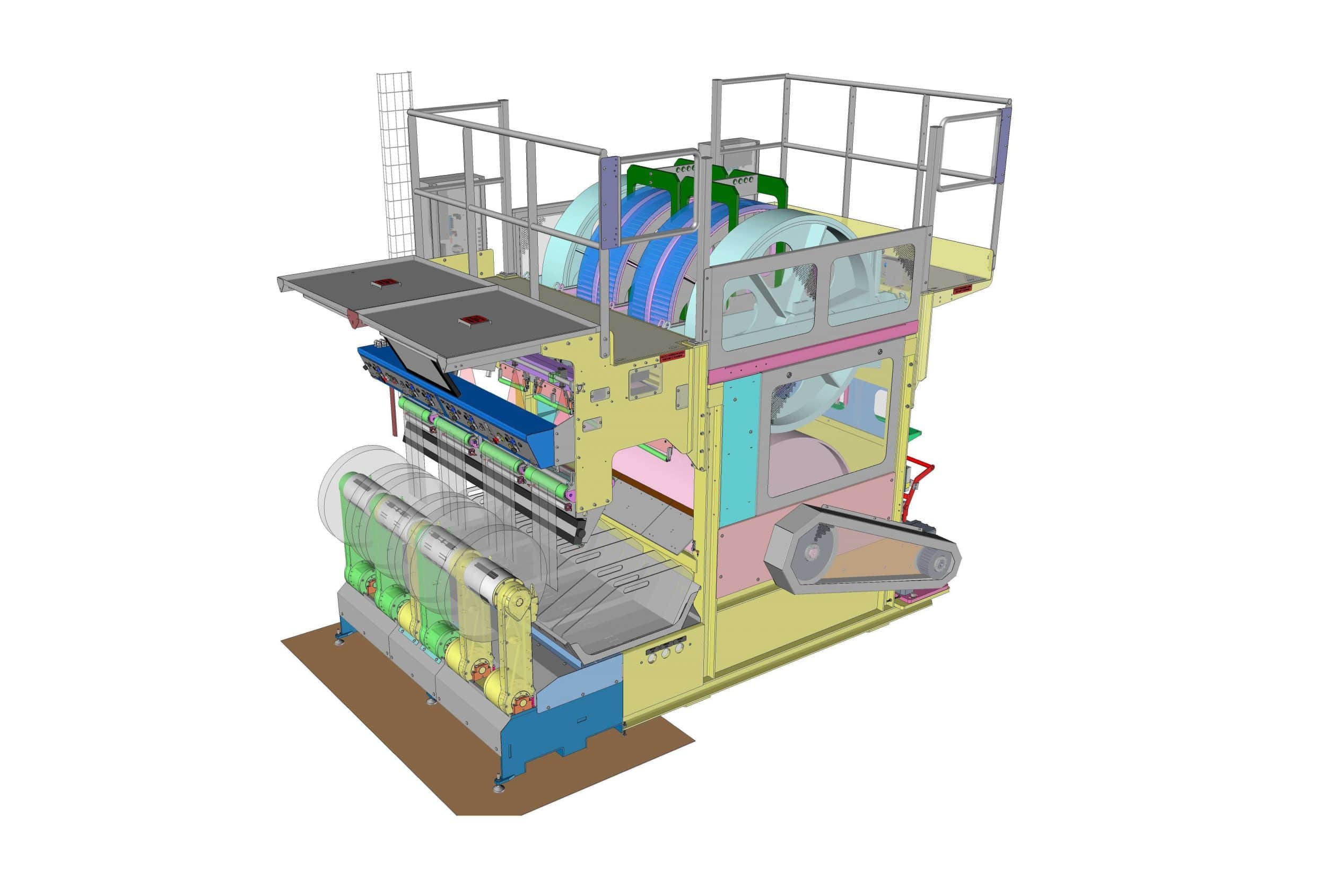

Development of a new food-processing machine

Throughout the entire process of designing machines or production lines, we prioritize good ergonomics for the end user. Our automation engineers develop sophisticated interfaces for controlling equipment and visualizing information communicated by the machine. We always seek to provide the best possible visibility of the process and good accessibility to settings thanks to practical accesses and openings.

For machines in the food industry, we know how to integrate into our designs all the constraints linked to the specificities of the sector: Hygiene, safety, cleanability, use of stainless steel or materials approved for food contact, product traceability, quality controls.

Some examples of achievements:

- Modelling of dosing equipment

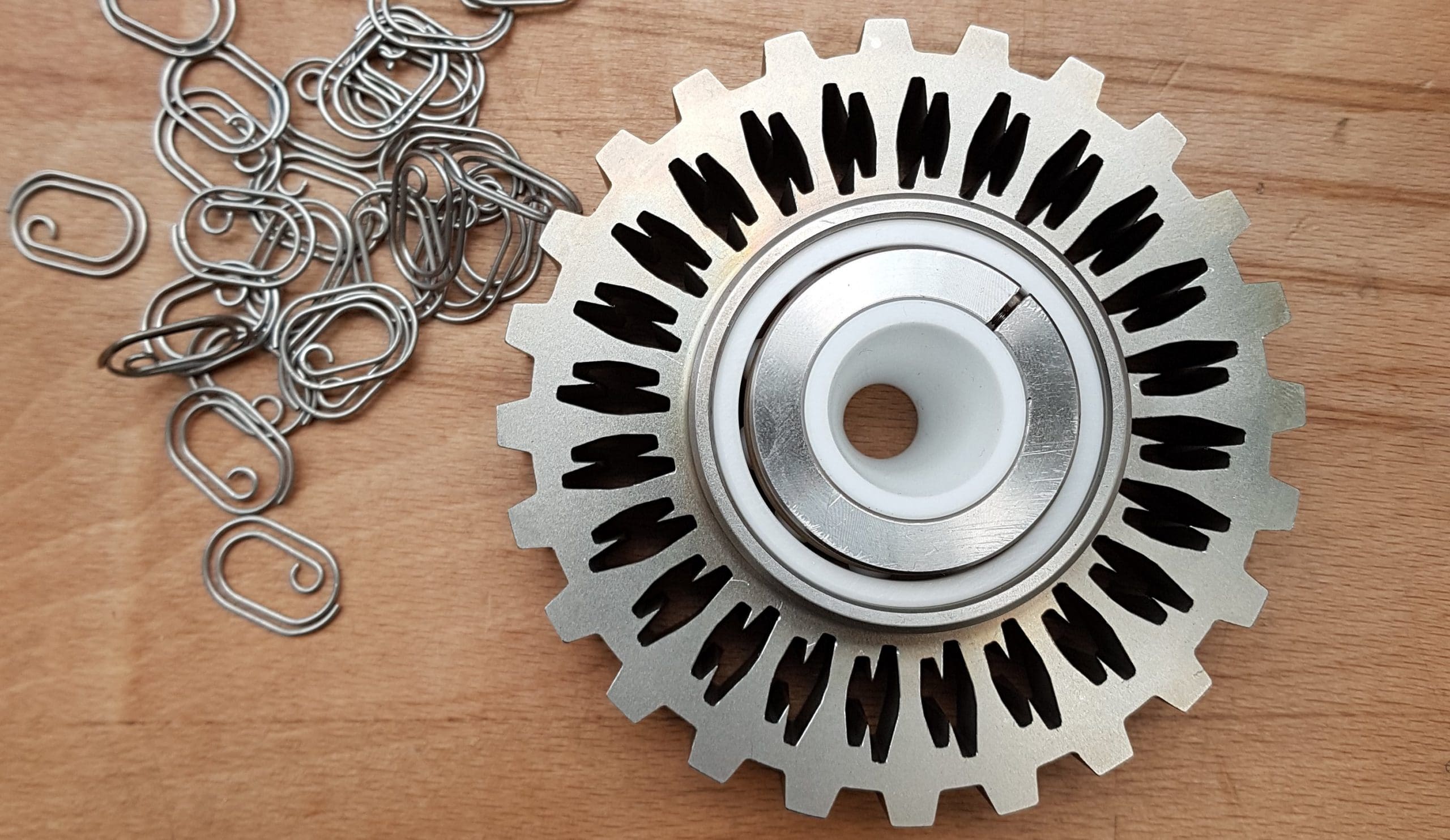

- Securing the transmission of a caramel tipper

- Special mechanisations for packaging line

- Integration of functions on production lines

- Integration of vision control on extrusion lines

- Feasibility study and determination of materials for robotic handling in cheese factories.

Improvement and new functions:

We participate in the improvement of existing functions or the integration of new technologies and innovative functions in continuous and sequential processes linked to the food-industry.

The objectives are for example:

- Facilitate operator tasks

- Increase the flexibility and productivity of production lines

SMI, your partner for custom-made food processing machinery

- You can’t find anything in the market that exactly meets your specific need?

- Are you having difficulty finding a single point of contact for a turnkey solution?

- Do you have a specific need regarding the optimization or design of a food processing machine?

We can be very creative and provide original solutions to sometimes very complex problems. As our slogan says, imagination is the source of innovation.

Where are we ?

Based in the Grand-Est region, our design office knows how to find the solutions adapted to your project thanks to our team, made up of engineers and technicians with varied skills: general mechanics, calculations, hydraulics and pneumatics, electricity, industrial automation and robotics, industrial vision, instrumentation.

In addition, Le Sur-Mesure Industriel has a panel of suppliers with very varied skills. These are most often located in a very close geographical area in order to guarantee maximum responsiveness.

A supplier for your agri-food equipment projects

- Does your company want to acquire a simple food production machine or a complete, automated packaging line?

- Do you want to better control the quality of your productions by adding, for example, a control system using machine vision or any other means of detection?

- Do you want to replace, modernize, improve, add functions to production or packaging equipment already in service in your company working in the food industry?

We can offer you reliable, efficient, custom-made solutions, taking into account the specificities of your food-industry: processing and packaging of meat, fish, fruit and vegetables, production of oils, dairy products, bakery products, drinks, or any other food product.

As you can see on the different pages, we know how to adapt to multiple areas of activity!

Taking your constraints into account

- All stainless steel design

- Cleanability

- Maximum reliability and availability of equipment

- Chemical resistance

- …

We provide solutions for your industry

- Manufacturing of customized, automated, robotic processing machines

- Packaging and packaging line

- Stainless steel equipment and measurement or control functions

- Improvement, modification, creation of industrial workstations

- Creation of lifting and handling tools (products or packaging)

- Automation of manual operations or tasks

- Machine protection

- Automated quality control, carried out directly on line

- Data recording, traceability

- Robotization

- Vision control, by camera and image analysis

- Digital servoing, positioning, regulation, brushless motorization

Your new food processing machine from A to Z

After having read your problem or your specifications, we take the time to analyse your need to offer you the equipment that best meets your expectations. It is essential for us to have an overview of your project and your objectives by collecting the right information from the beginning of the project. We are quite used to respecting confidentiality agreements if the application requires it.

We are then able to make you a technical and commercial proposal, including all the stages of realizing your project: feasibility, mechanical and electrical study, supply of parts and components, assembly, wiring and commissioning, delivery of equipment and on-site training.

Complete control over the operation of your equipment

The study and detailed design of your new food industry equipment facilitates its operation and maintenance thanks to the complete technical documentation provided upon delivery: CAD design, detailed and assembly drawings, parts lists, electrical and pneumatic diagrams, source programs, user and maintenance manual.

This represents a huge advantage for all departments in your company, which quickly become autonomous in the use and maintenance of the equipment we supply. You have complete control over all aspects of managing your equipment.

After-sales service, provided by the creator and supplier of the equipment

Throughout the life of the equipment, we will be your preferred contact for any additional information you may need on its use, transformation or duplication.

You can also count on our reliability, responsiveness and flexibility to assist you in maintenance operations. We have always been in close contact with our historical customers since the creation of the company in 1991 to support them and help them maintain the equipment still in operation, in France or around the world.

Control equipment for the food industry

- Are you looking to make your food processing equipment more reliable?

- Would you like to improve the quality and consistency of your manufacturing or packaging processes?

SMI is your contact of choice in the Grand-Est to support you in all your projects involving the selection, integration or creation and implementation of measurement and control methods.

We bring a neutral perspective to your issues and select the best technologies and products to meet your detection, monitoring and quality control needs.

Food industry 4.0

The food industry is subject to ever-increasing constraints in terms of speed, quality and regularity. It is becoming increasingly important to have high-performance machines equipped with technologies that can monitor important characteristics to ensure the quality of outgoing products and their proper packaging.

When designing our equipment and machines, we almost systematically integrate hardware, sensors and control systems to measure the important characteristics of the product processed by the equipment. The acquisition of this data makes it possible to collect very useful information during diagnostics, to understand phenomena, drifts for example, and to fully control the operation of a piece of equipment. The analysed data also makes it possible to automate compensations or certain adjustments.

Production data is also obviously recorded and communicated: equipment status, rate, reject rate, counters, defects, etc. All of these analyses are very useful for controlled, quality food production.

Questions fréquemment posées sur les machines d’assemblage ou les lignes de production

Frequently asked questions

Can you help us create a machine for the food industry?

In which geographical area do you operate for the supply of agri-food equipment?

What type of machine do you specialize in?

Tell us about your topic, we will tell you how we can provide you with answers and technical solutions.