Mechanical engineering

Numerical simulation and mechanical design services

Le Sur-Mesure Industriel, a design office for industry, is your partner of choice for simulation, the development of mechanical solutions, industrialisation, the manufacture of parts or the design of prototypes or machines related to your products.

Mechanical projects?

Is your company looking to subcontract or outsource all or part of its mechanical engineering design activities? Do you have a design or digital simulation requirement that falls outside your area of expertise? Do you want to produce a prototype to validate a design or test an idea or an innovative concept for your products?

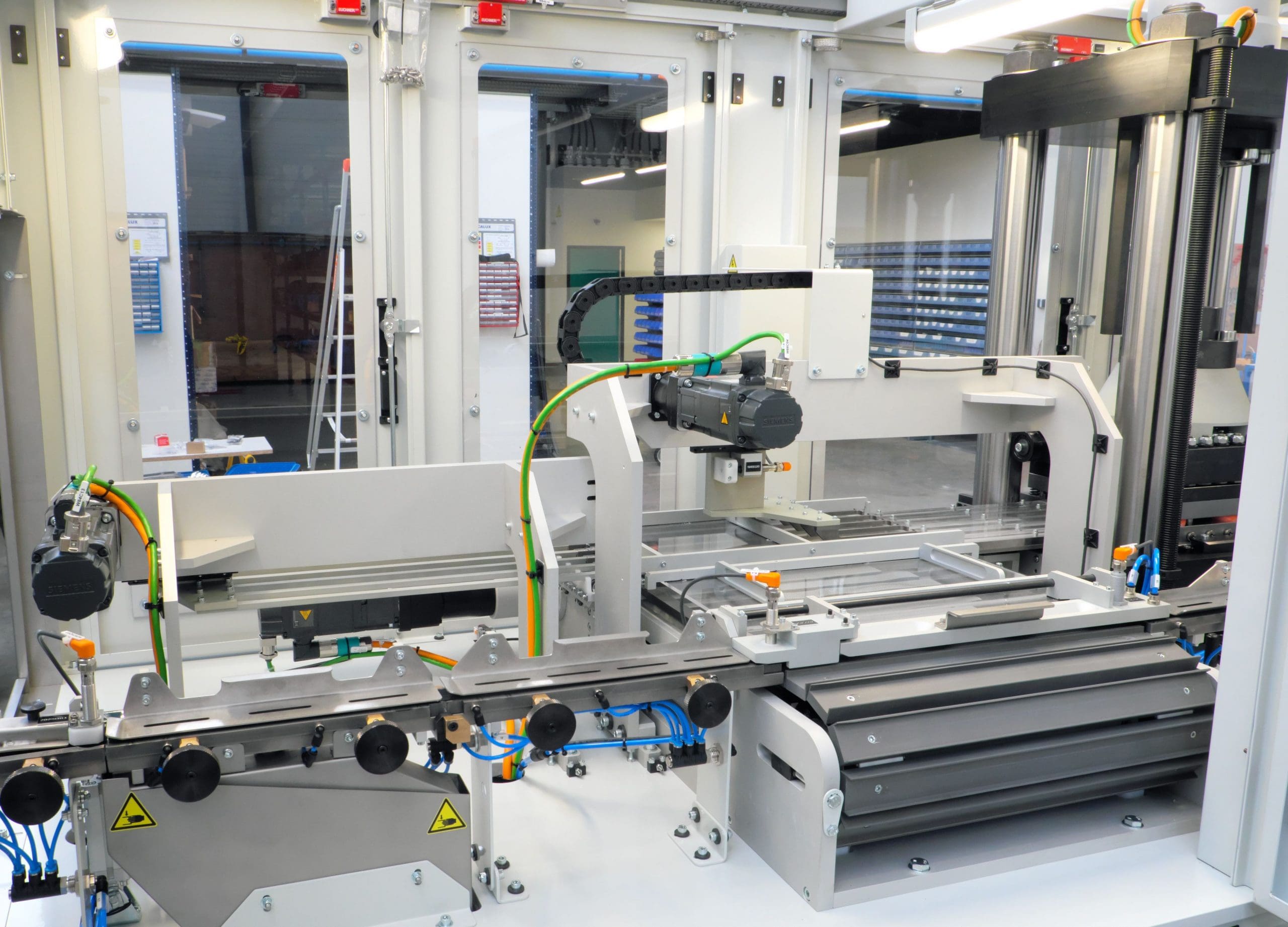

Do you have an idea for a machine and are looking for a design office to industrialise it and move on to the manufacturing stage of your mechanical assembly?

Are you facing an overload of activity and would like to entrust mechanical studies, tool development, mechanical assembly design, casing design, functional assemblies or entire machines to an external design office, a trusted partner?

Our mechanical design office

We are at your service throughout France and in neighbouring countries such as Switzerland, Germany, Belgium and Luxembourg, offering you a range of services meeting your needs.

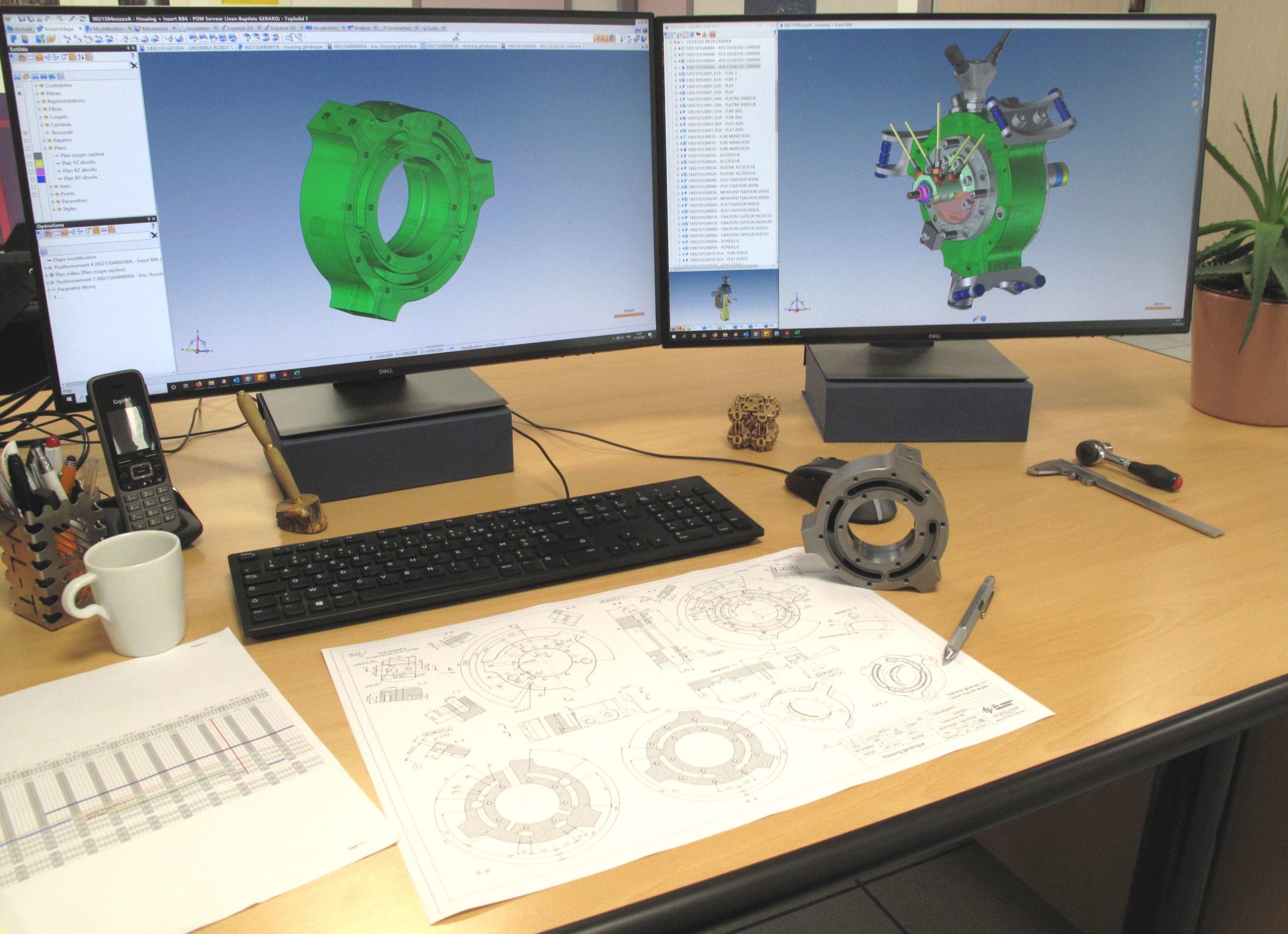

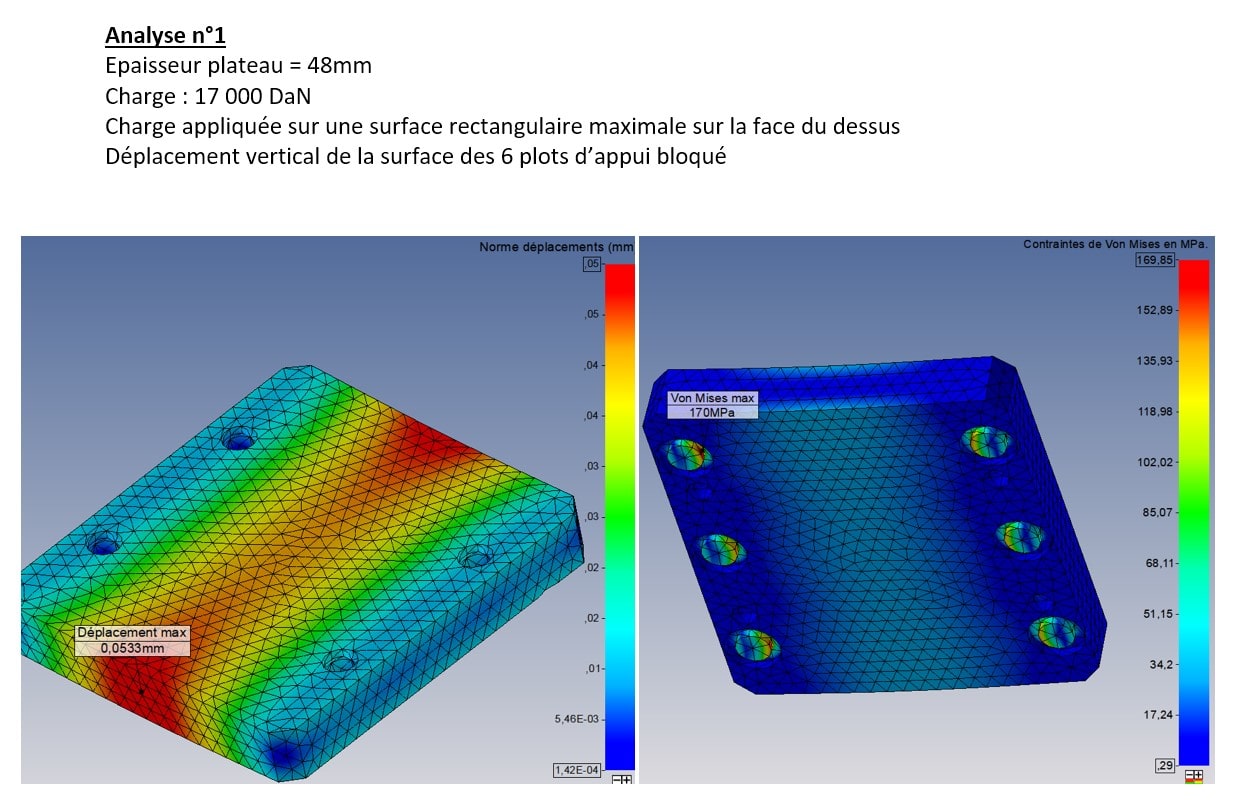

Our engineers and technicians, based at the company’s office in Thaon les Vosges in eastern France, are specialists in mechanical calculations and 3D design. They are on hand to offer you all the services of a mechanical engineering design office to meet your needs: design, calculations, kinematic or digital simulation.

We can assist you or take complete charge of a study, delivering CAD files, manufacturing and assembly drawings, and bills of materials listing all the parts and components making up the equipment. Depending on your needs, our studies can also include the production and supply of all technical documents relating to the project: sizing calculations, user manuals, risk analysis, etc.

Here are just a few examples of what our design office has achieved

- Aluminium strip stamping presses

- Production of prototypes

- Special machines and welding jigs (plasma welding, resistance welding, laser welding)

- Laser marking machines

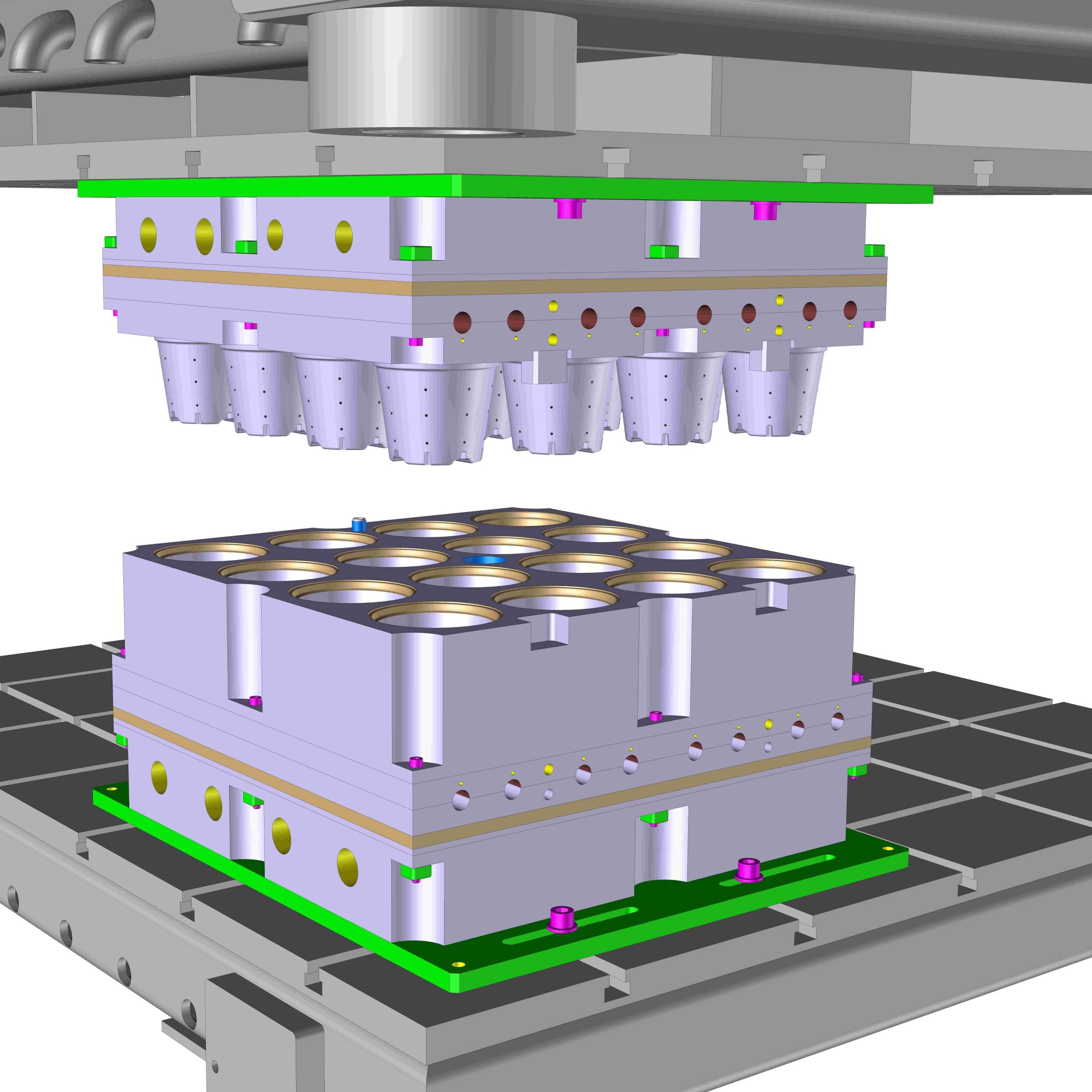

- Equipment for stamping presses, display presses and laminating presses

- Press tool maintenance equipment

- Part shaping machines (bending, punching, shaping, etc.)

- Machines d’assemblage de composants mécaniques

- Mechanical component assembly machines

- Fatigue testing station for mechanical sub-assemblies

- Lifting and maintenance tools for public works machinery

- Machining assembly for medical prostheses

- Special spring grinding machines

- Product industrialisation

- 3D modelling of foundry parts

- Design and industrialisation of machine casings

- Kinematic simulation, cam tracing, mechanical transmission

- Ergonomic workshop trolleys

- Design of robotic cells for loading machining centres

- Machine retrofitting

- Research and development of assembly solutions for new products

- Calculation and integration of brushless motors in power transmissions

SMI: a design office that knows how to adapt

If necessary, we can adapt to the design software used by our customers. In this way, the documents produced are in the native file format of the software they use on a daily basis.

The construction and assembly trees, as well as all the dimensions, remain configurable in this case, and it is very easy to use, update, modify or duplicate the work carried out afterwards.

We also deal with subjects by fully immersing ourselves in our customers’ development methods: use of their numbering logic for references, recovery of drawing background cartridges, use of standard components favoured by the customer. In this way, our research and design services remain fully integrated into the client’s workflow.

Thanks to all our previous experience, we also know how to adapt to different industrial contexts, depending on the sector of activity. For example, we have already worked with, or would be interested in working with, companies in the automotive, aerospace, rail, medical and food industries. But also in the sectors of electrical engineering, energy, industry in the broadest sense and public works.

Expertise and extensive experience in machine developpement

“The configuration of our team and our open-mindedness enable us to tackle a multitude of varied topics.”

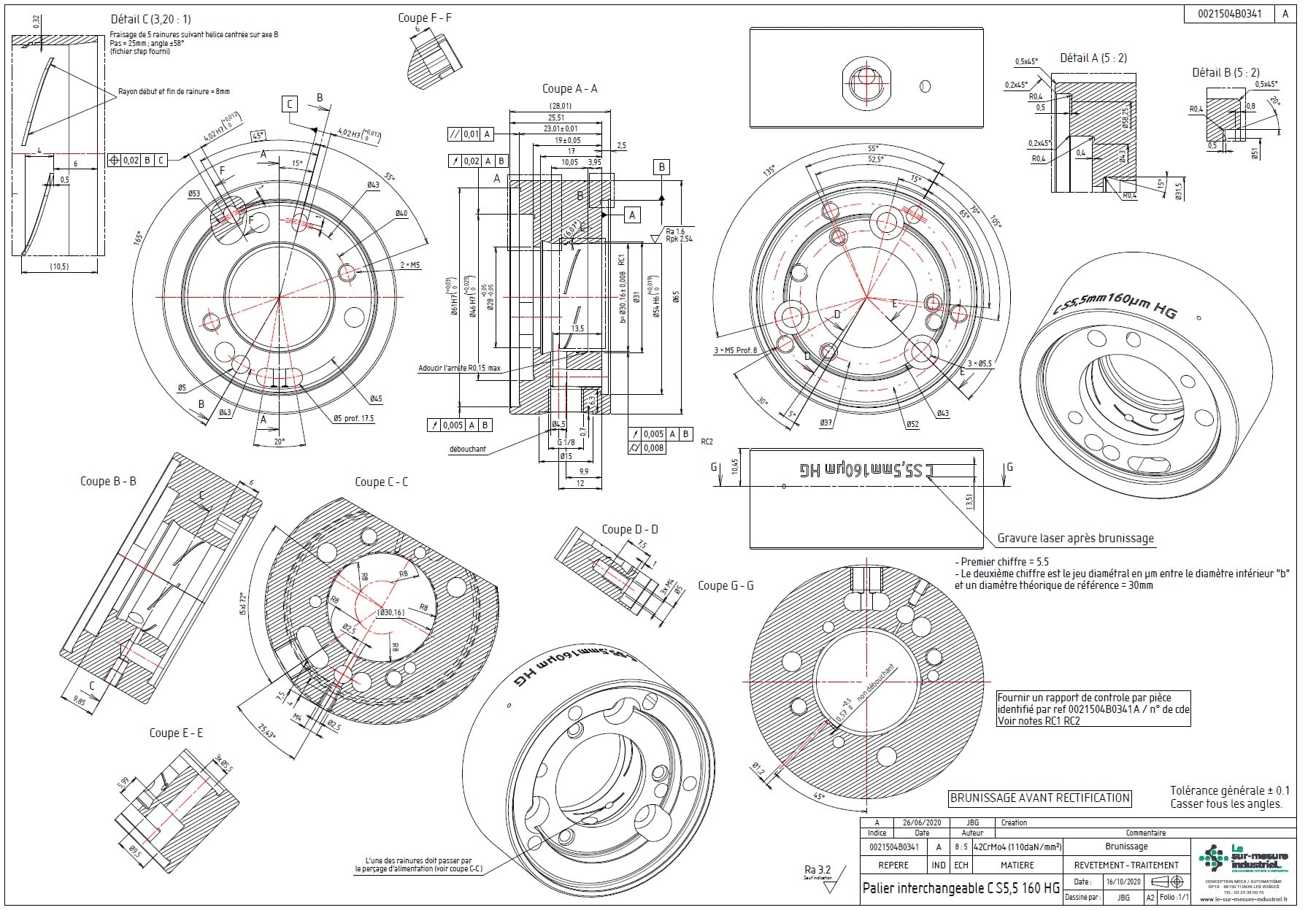

By benefiting from the affinities and previous experience of all our designers, we are able to handle high-precision mechanical studies, such as the design and development of tooling with dimensional and geometric accuracies of less than 1 µm. We also study, design and manufacture large-scale mechanical structures and assemblies (footbridges, mechanically-welded pylons, machined mechanised welding machine frames, etc.).

Every day, we work to develop custom-made solutions for our customers, adapted to their products, using all kinds of mechanical principles and processes. The equipment and mechanical assemblies we develop are always designed to the highest standards, with the constant aim of ensuring reliability.

SMI, your partner in product industrialisation

When we design a mechanical sub-assembly or a machine, we choose the manufacturing method that will be used to produce each part: this is industrialisation. In this way, we adapt the design of the parts and integrate directly into the design the constraints or specific features associated with the manufacturing and assembly methods envisaged.

For example, we worked with one of our customers looking for solutions for the manufacture of its concept. They called us on to benefit from our knowledge in product design and industrialisation.

Based on the geometries and functionalities of the equipment he had imagined, we used our digital resources and redesigned all the mechanical parts to make them feasible. Most of the parts for this project were made in sheet metal. The mechanical redesign therefore involved defining the flat cut-outs (used to laser-cut the sheet metal), the bending zones and their geometries, as well as the mortise-and-tenon joints and the mechanical welding drawings.

We provided our customer with the complete manufacturing documentation for its products: detailed CAD modelling, detailed drawings of the parts, assembly drawings, an exhaustive bill of material including all commercial components, right down to the screws and bolts. As a result, the customer was autonomous for the rest of the manufacturing operations with specialist suppliers.

If you wish, our services can also include the construction and commissioning of equipment for ready for use solutions. We manage the supplying of components and the production of parts with our panel of suppliers. We assemble mechanical sub-assemblies, assemble and wire equipment, and can carry out tests on prototypes, tooling, or any mechanical assembly, with or without the use of automation.