Paper / Wood / Plastic / Metal

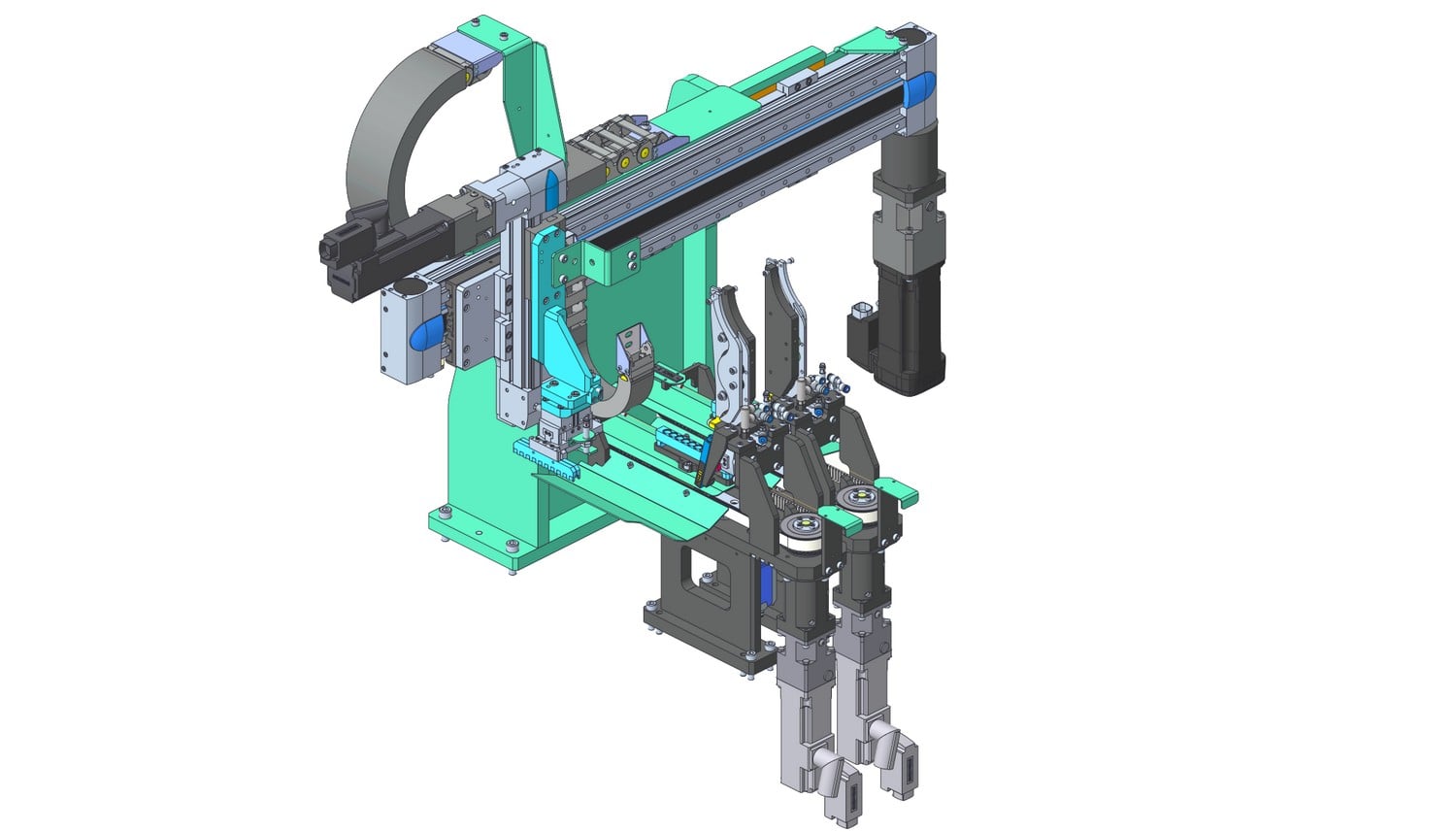

Design and manufacture of special machines

SMI, your partner for a special machine

Can’t find anything on the market that exactly meets your specific needs?

Do you need to draw on several areas of expertise for your project and are having trouble finding a single partner for a turnkey solution?

As our slogan says, the imagination of our teams is the source of innovation. We can be very inventive and come up with original solutions to sometimes very complex problems.

With over 30 years’ experience in the design of special machines, we know how to find the right solutions for your project. Based in the Grand-Est region of France, Le Sur-Mesure Industriel is located in a very rich industrial area, with a range of suppliers with a wide variety of skills within easy reach. Our team of engineers and technicians in general mechanics, hydraulics and pneumatics, electricity, industrial automation and robotics is at your service to design and manufacture your parts, components, tooling, equipment or complete machines.

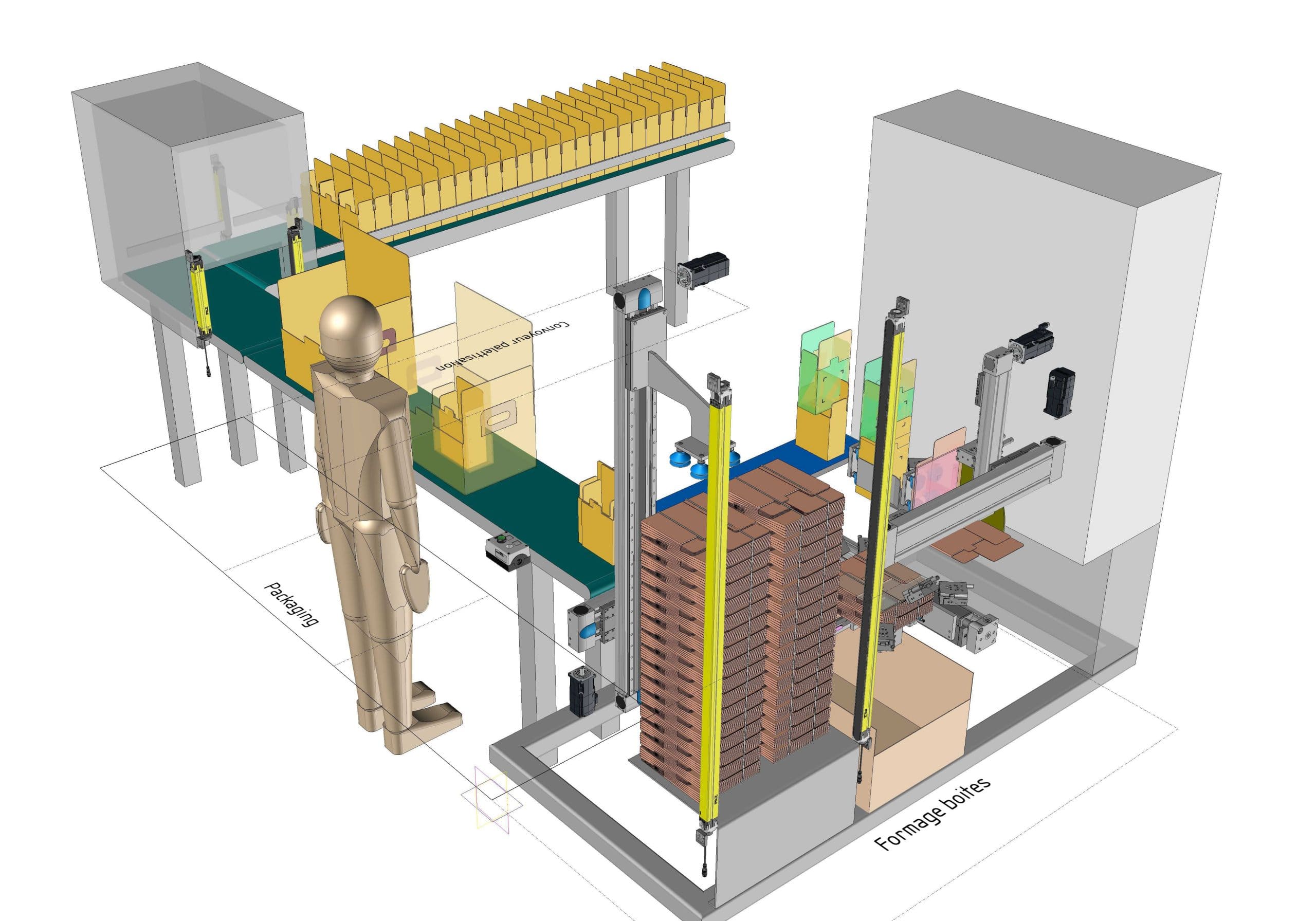

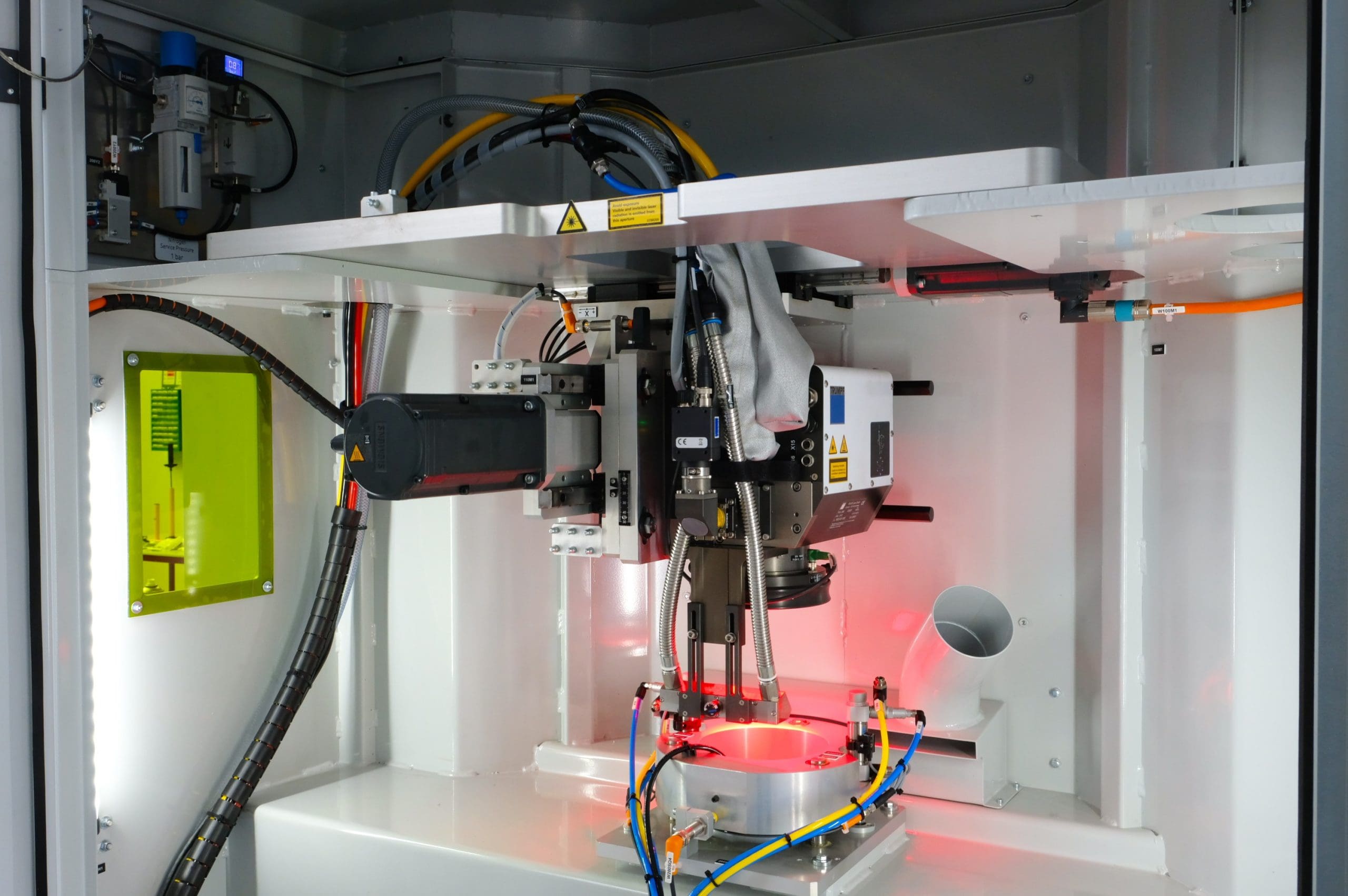

Is your company looking to acquire a simple mechanical assembly machine or a complete automated production line? Would you like to improve the quality of your production by adding a machine vision control system, for example? Do you have a piece of equipment in operation in your company that you would like to modernise, improve, add functions to or simply update?

We can offer you reliable, effective, custom-made solutions, taking into account the specific features of your field of activity. As you can see from the various pages, we know how to adapt to a wide range of business sectors, and we’re more than happy to help you discover yours!

Paper

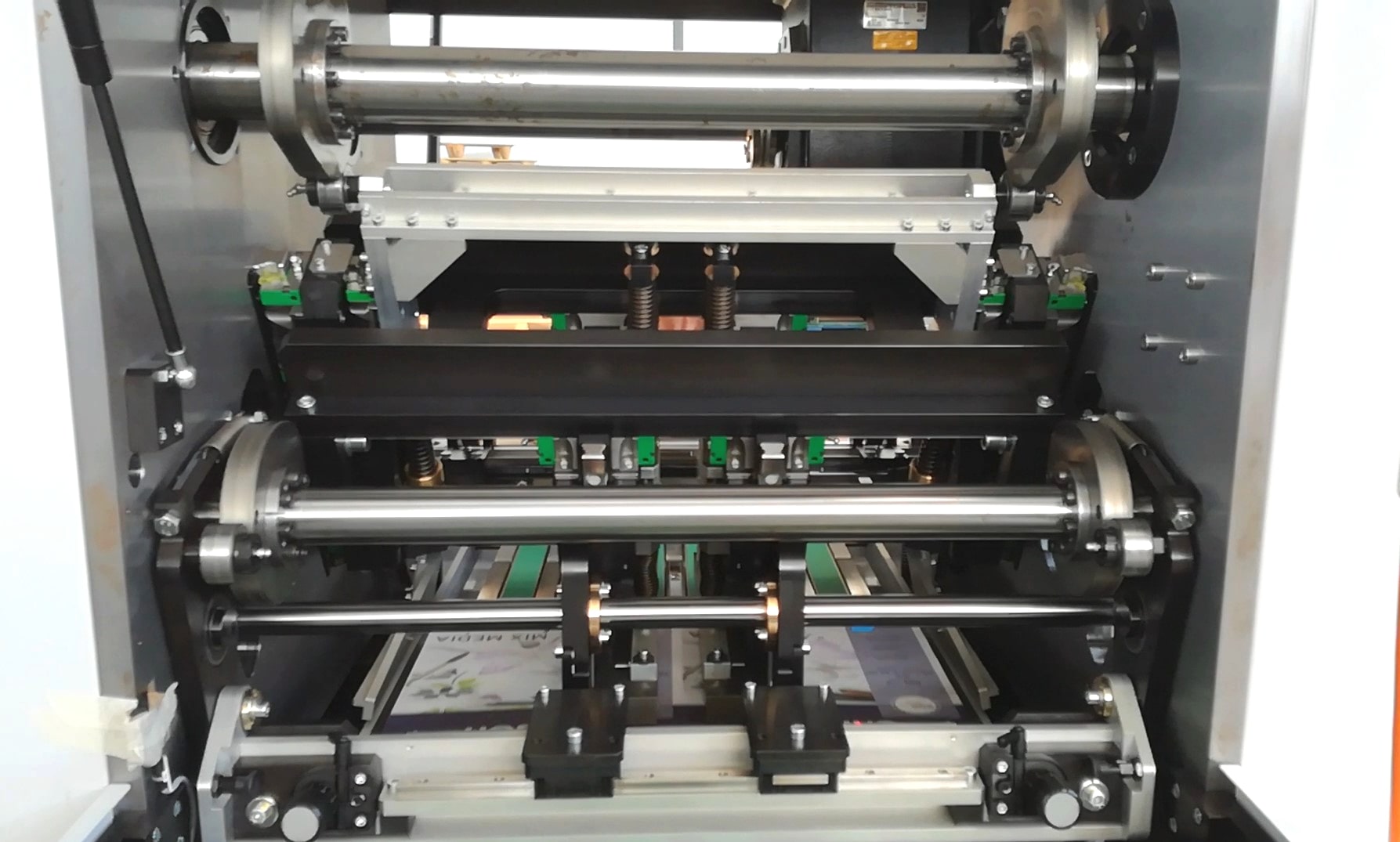

- Guillotines for shaping school exercise books and notebooks

- Cam and/or brushless motorised guillotines

- Packaging line, cam machine

- Continuous improvement of paper machines

- Customised casing

- On-the-fly marking and stamping of watercolour paper

- Feeder for large-format sheets

- Laminating presses for quality control of decor paper

- Counter winder, tube wrapping

Wood

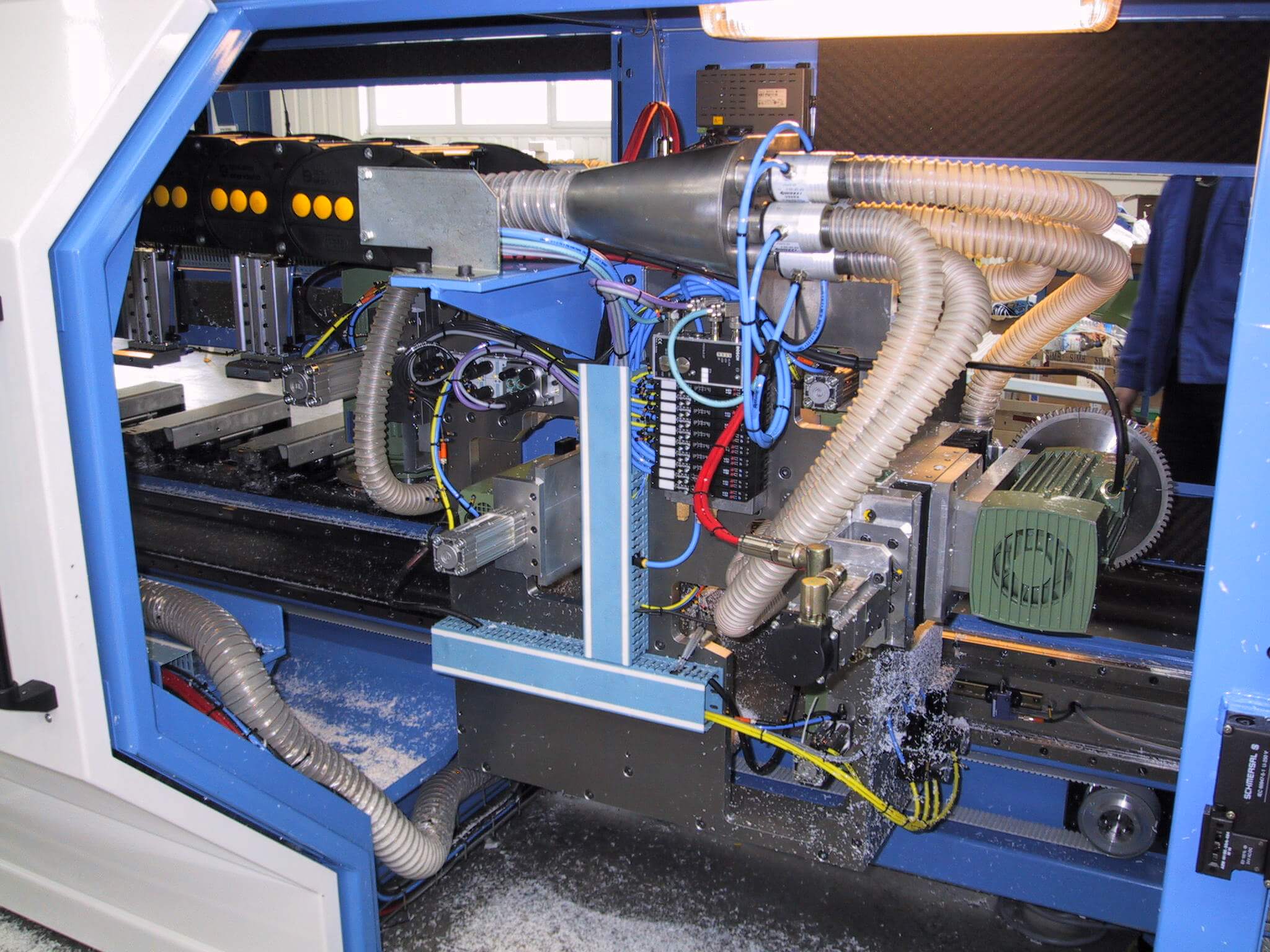

- Machine for machining stair treads

- Cross-cut saw and multi-blade saws for wood packaging

- Design of equipment for preparing panels for timber-frame houses (MOB)

- Measuring table

- Lab presses for qualifying decorative panels and glued panels

- Feasibility studies for cooperage equipment

- Particle mixers

- Mechanical design of vision control machines for wood qualification

- Moulds, filters and equipment for shaping parts from wood fibres

Plastic

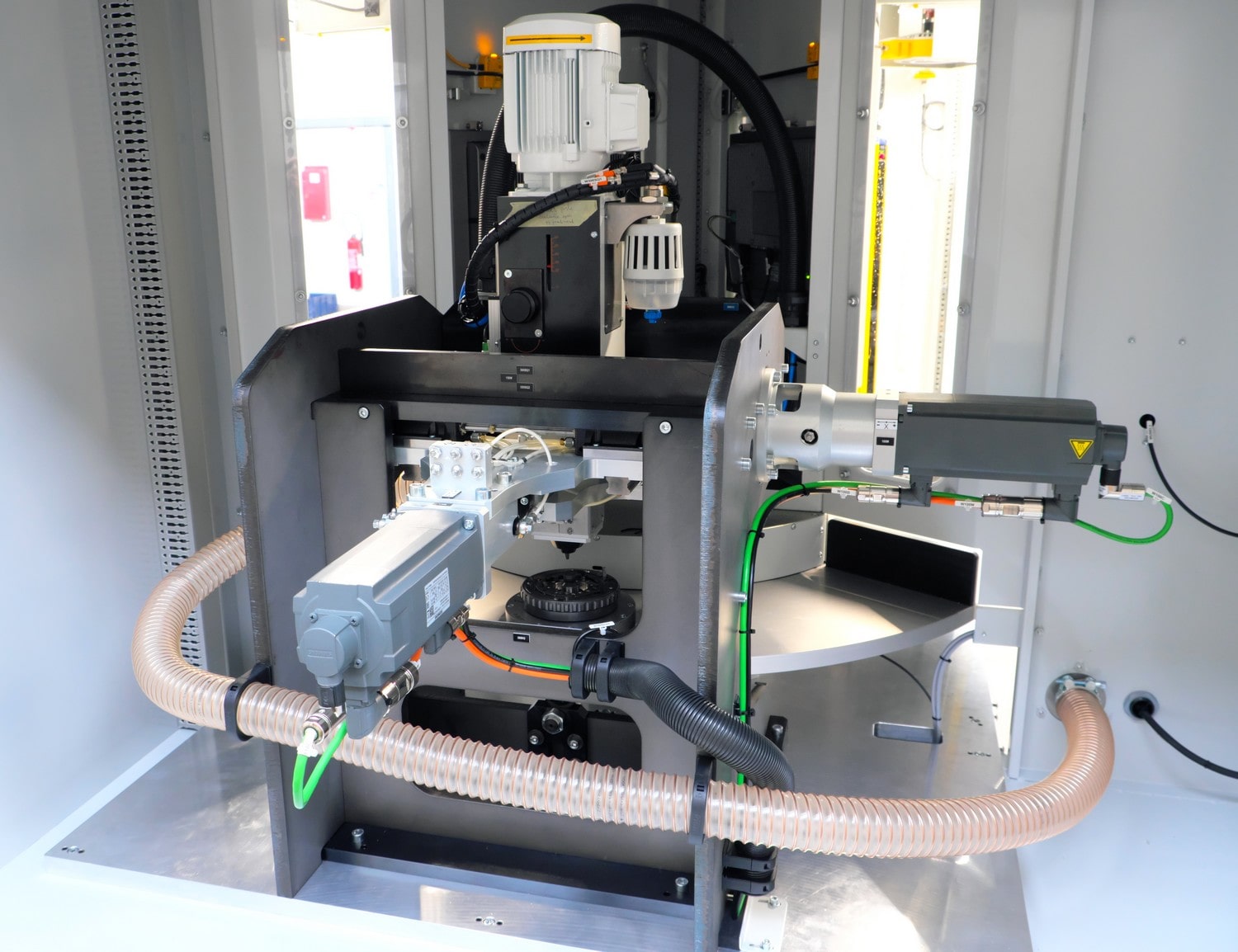

- Multi-axis machining centre for industrial PVC joinery (5 machining spindles, 3 servo motors, choice of machining operations via function blocks, high-speed suction)

- Test machine for polyethylene sheet flow welding

- Carousel machines for cutting polycarbonate injection sprues

Custom-made solutions in every field

We design and manufacture machines for a wide range of industries, including test benches and machines for the medical sector, guillotines for paper products, machining centres for plastics and sawing machines for wood. Production and control equipment for the food and aerospace industries.

We are also present in the leisure secture, where we design and manufacture descent trolleys and braking systems for major zip lines, which can be found all over the world. From structural strength calculations to measuring cable speed and bearing temperature rise, we are involved at every stage of development.

We also supply customers in the automotive sector, for whom we manufacture everything from simple mechanical tools to fully automated assembly machines.

Feasibility

We adapt to the configuration and maturity of your project. In some cases, the request is based on very precise specifications. For other projects, we help our customers to clearly express their expectations.

Sometimes, to test an idea, a concept, or simply to define and quantify the need, a feasibility phase is necessary. This enables us and our customers to explore a problem in order to define whether a relevant solution can be provided, and within what limits.

This preliminary study takes place upstream of the design phase. It is of great benefit to our customers, as it gives them a clear idea of the technological content of the machines and helps to secure a budget estimate.

Design of a special machine

We are equipped with high-performance hardware and software for CAD, schematics, robotics and programming. If the use of a particular software package is required, we can adapt to the specific needs of our customers, so as to retain the native file formats they are used to.

Right from the design stage, we also incorporate recommendations relating to HSE, ergonomics and equipment safety, to minimise risks to operators. Depending on the configuration and the hazards involved, this may involve the use of immaterial safety barriers, enclosures or covers, monitored doors and openings, or protective mesh zones when robots are used.

All our machines are designed to meet the mandatory safety levels required by the Machinery Directive and the CE standard, whether they are operated inside or outside the European Union. Our machines are CE certified and often pass a conformity check carried out by an approved inspection and verification body.

All our machines are designed with the necessary and compulsory level of safety required by the Machinery Directive and CE standard, whether they are operated within or outside the European Union. Our machines are CE certified and often undergo a conformity check by an approved inspection and verification body.

Manufacture, assembly and fine-tuning of a special machine

The trust and proximity with all our suppliers is a guarantee of quality and allows us to react quickly. In the field of mechanical manufacturing, they produce our machined parts, with specific treatments or finishes. They also produce our sheet metal parts and mechanically welded assemblies, for the production of chassis that are often coated with epoxy powder paint in the colour requested by the customer.

Consultation and monitoring of supply deadlines with our suppliers are an integral part of our service during the design and production phases, to provide a clear vision of the project and meet the deadlines and budgets defined with our customers.

We draw up the electrical diagrams, the automation, the wiring and the complete manufacture of the cabinet. The machine is assembled in our assembly hall, where it is commissioned and tested for the first time. A project acceptance phase very often takes place on our premises, in the presence of the customer, to ensure that everything meets expectations before shipment.