Our services

Engineering & Design

Often at the heart of the design process, equipment design is one of the most important stages in many projects.

Industrial Automation

To bring any equipment to life, it’s essential to have automation equipment and efficient programming.

Special Machinery / Tools

Together with our customers, we analyse and implement a wide range of customized projects.

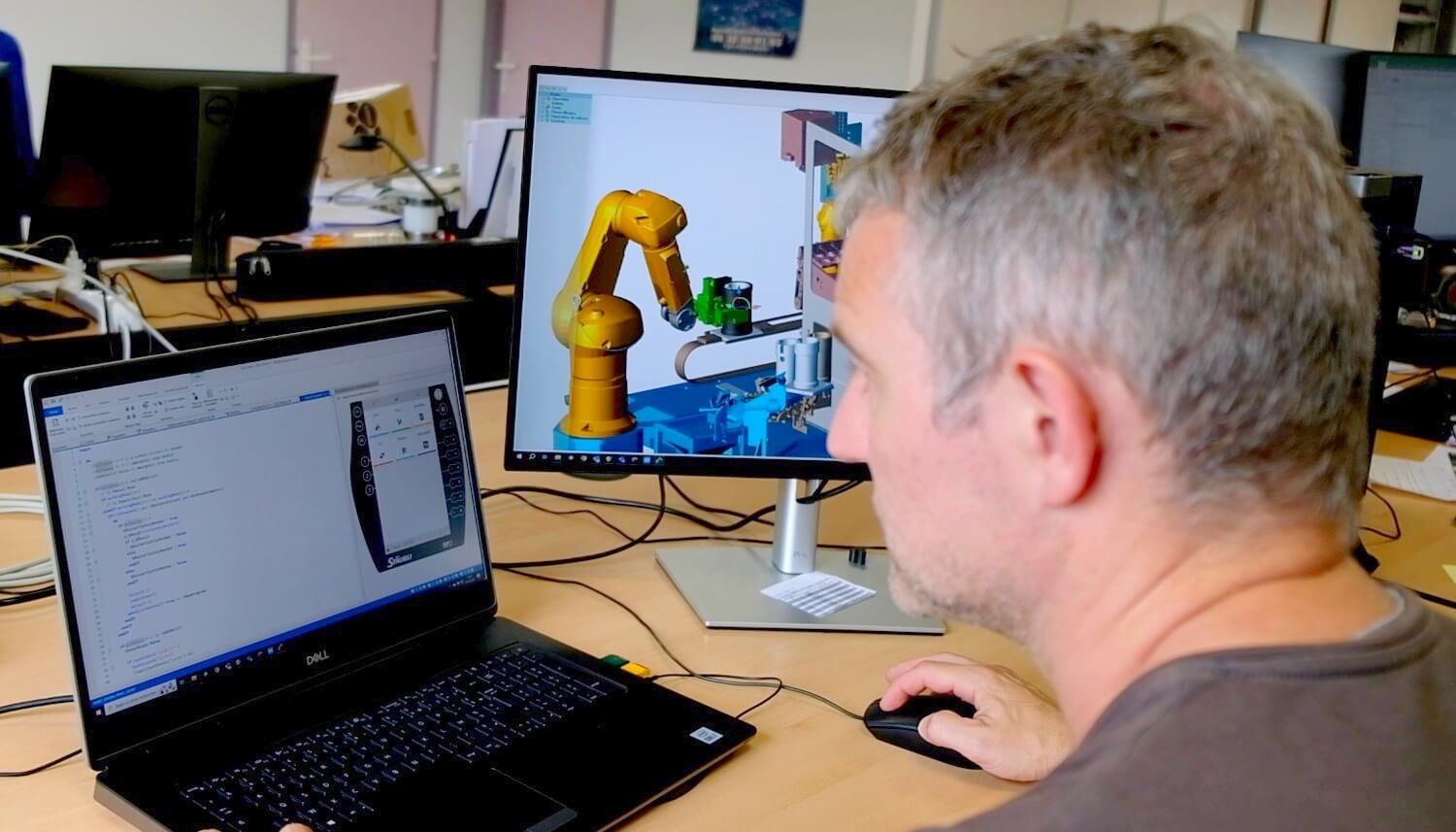

Robotics

We can support and study any project involving robotisation.

Research & development

In response to a specific problem, we put our expertise and creativity at the service of our customers in the search for innovative solutions.

Calculations / Simulation

Industrial engineering: comprehensive support from design to training

Le Sur-Mesure Industriel works alongside manufacturers during all phases of a project, or carries it out in its entirety, from the feasibility study through to installation and commissioning. Our team can also take charge of training your staff, right up to the point where operators are fully conversant with the equipment.

As part of our project management services, we assist companies by helping them to analyse all the technical constraints involved in achieving perfectly controlled industrial projects, in compliance with the regulations and standards in force. The industrial engineering services we offer enable manufacturers to secure the implementation of their projects from a technical, economic or strategic point of view. Our project management includes post-completion monitoring and detailed training.

This enables your company to maximise profitability and reduce production stoppages. We supply a user manual for all our machines, available in French and/or English depending on the destination country.

Our support in industrial engineering and industrial project management

Are you looking to solve an industrial problem and need support in managing your project from start to finish? Is your company looking to develop a manufacturing or industrialisation process, or carry out mechanisation or automation studies, and do you need support? Do you want to improve an existing means of production?

Thanks to our multidisciplinary teams, an open mind and a good knowledge of mathematical and IT tools, we are able to grasp the different aspects and components of an industrial project or system.

For over 30 years, our core expertise has been the development of techniques and industrial processes, as well as mechanical engineering. We design products in 3D and represent the stages in their manufacture, model complete machines, simulate workflows and estimate production rates.

Our experience in the management of technical studies, project management, support in drawing up specifications and the number of special machines developed for our customers make us a solid partner.

Do you need assistance with mechanical design, automation, manufacturing processes, industrial organisation, quality and project management, and want a single point of contact? Le Sur-Mesure Industriel can provide you with solutions. Call us to discuss the management of your project.

Do you want to subcontract all or part of a project because you lack in-house resources? Do you need a partner to take charge of the design and production of your equipment, monitor progress and keep you regularly informed of the schedule? You can send your requests and specifications to our e-mail address.

Are you also concerned about the quality of follow-up after production start-up, and is staff training a major part of your business? Call on our team for all your industrial projects.

You are right to place your trust in SMI. Our industrial engineering skills enable us to offer our design and project management services to the various production sectors of small, medium-sized and very large companies. The engineers and technicians who make up our design office are capable of designing, managing, organising and optimising the operation of complex production systems. Systems that integrate financial, tangible and intangible resources and the flow of materials, energy and information…

Industrial engineering takes up the challenge

Machine engineering is becoming increasingly technical, requiring synergy throughout the project between our mechanical, electrical and automation designers and programmers. We even go so far as to use industrial IT for data feedback and logging or machine vision, for example.

Based on multiple input data, we produce documents (calculation notes, drawings, specifications) taking into account all the constraints arising from the interfaces and the context. As a central point of contact, in liaison with customers, suppliers and various partners, Le Sur-mesure Industriel builds innovative, high-performance industrial assemblies, while also providing support and training for users.

In a complex economic environment, our experience provides you with clear, precise project management thanks to regular monitoring.

What is engineering?

Engineering covers all the stages in a project. It starts with the design studies, then continues with the manufacture of the equipment, through to production start-up and user training.

The main requirements of industrial engineering are linked to the customer’s rules and specifications, environmental constraints and timing. Industrial engineering also takes account of local and international norms, standards and regulations. Once the studies have been completed, custom-made industrial engineering provides the customer with designs, calculation notes, drawings and specifications, and proposes the production of sub-assemblies or complex assemblies.

The multidisciplinary nature of our teams means that we are present in a wide range of industrial sectors: automotive, aerospace, military, paper mills involving cellulose-based manufacturing processes (paper, cardboard), as well as the food industry. We are also present in the pharmaceutical and medical sectors, where we are involved in improving production processes, for example.

Some projects call for the robotisation of production resources, either to increase productivity or to reduce the risks associated with repetitive movements for operators (e.g. musculoskeletal disorders, MSDs). In this case, the project includes a phase of observing production and flows with the customer, in order to optimise the technical solutions proposed in line with the gains sought: better management of flows, increased production rates, safer working conditions for personnel. Our teams provide industrial engineering and project management support, from the feasibility study right through to the installation of the equipment in your plant, including staff training on the machine in your company.

We are also called on to study energy conversion and recovery processes, in particular with systems including refrigerant gases, pumps and heat exchangers, in the automotive and air-conditioning sectors.