Engineering and design

Your project

Are you experiencing a new need for the production of your products, for the improvement of control methods, for the creation of a test bench or for any other requirements?

Our design office in France will assist you in drafting your specifications on which the future design will be based.

We prioritize technological choices during the pre-study phase to provide the closest possible solution to your needs

With our expertise in engineering and mechanical design in the industry, advice on innovative technical solutions based on an analysis of the operation will be provided to you. This can sometimes take the thinking beyond your specifications.

Whether your field of activity is the food industry, automotive, wood or other, our experience gives us the ability to respond positively to the majority of requests.

Methodology and progress of a project

- Definition and understanding of the need.

- Functional analysis

- Feasibility study

- Research of processes, technical principles

- Proposal and discussion of solutions

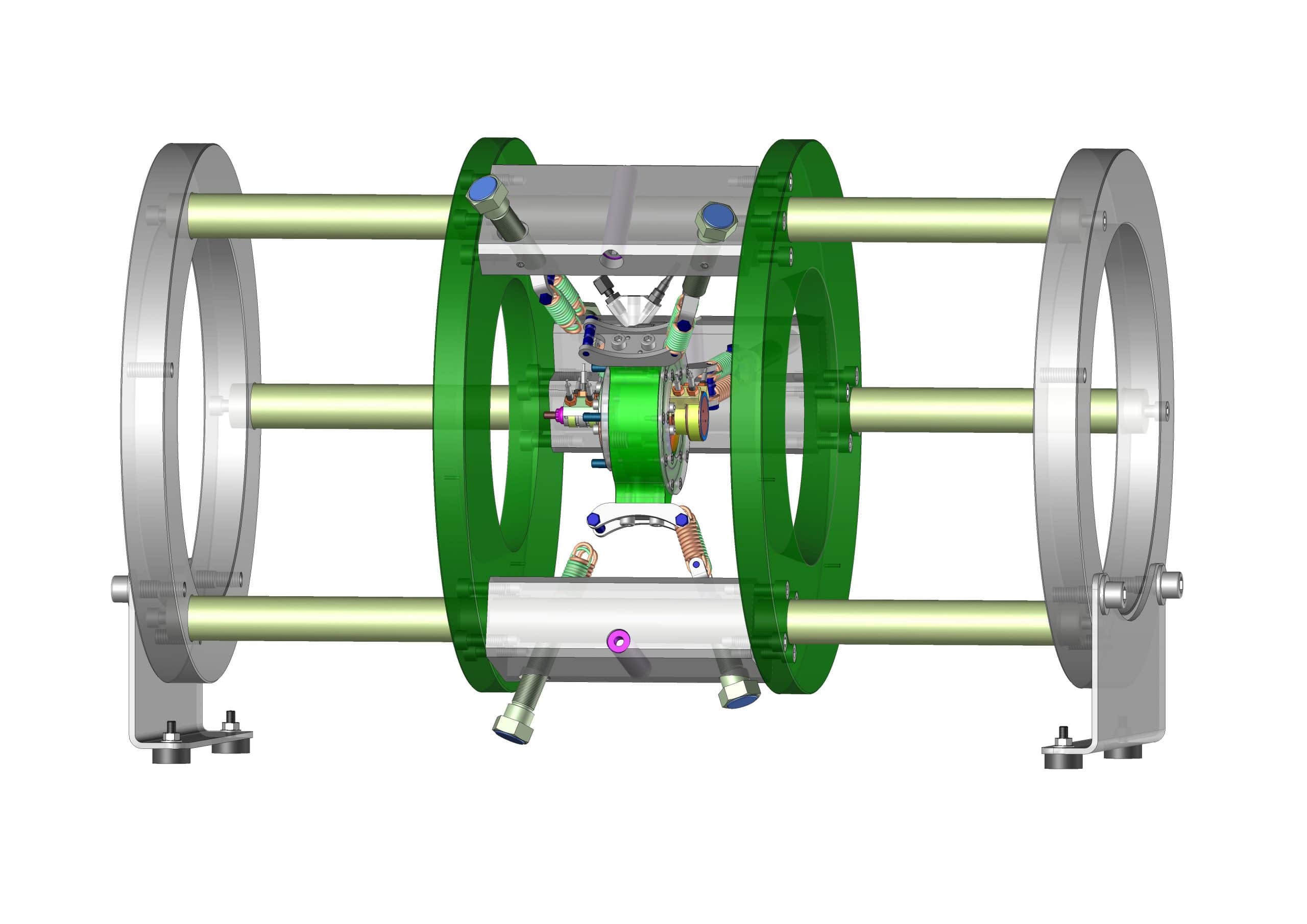

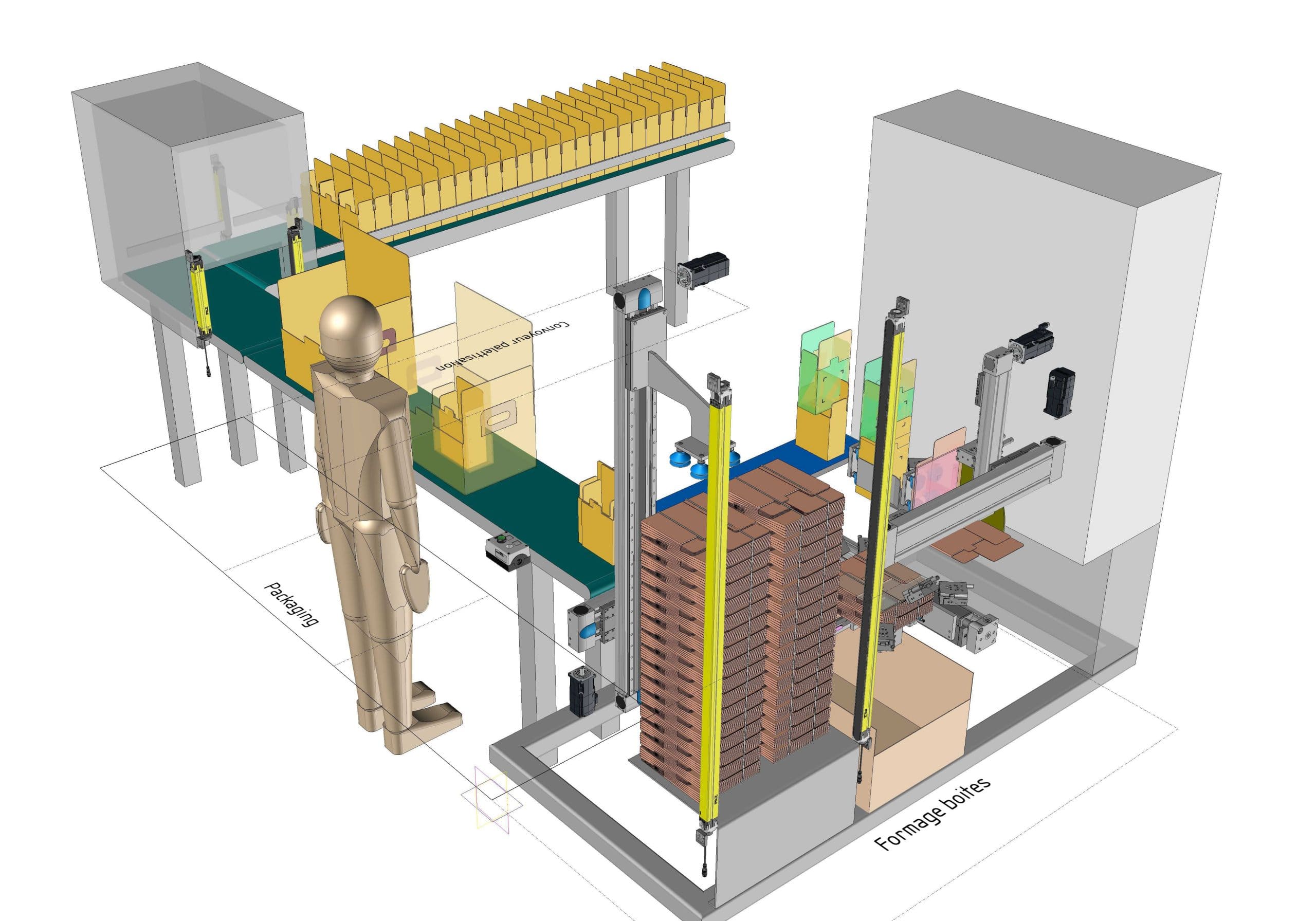

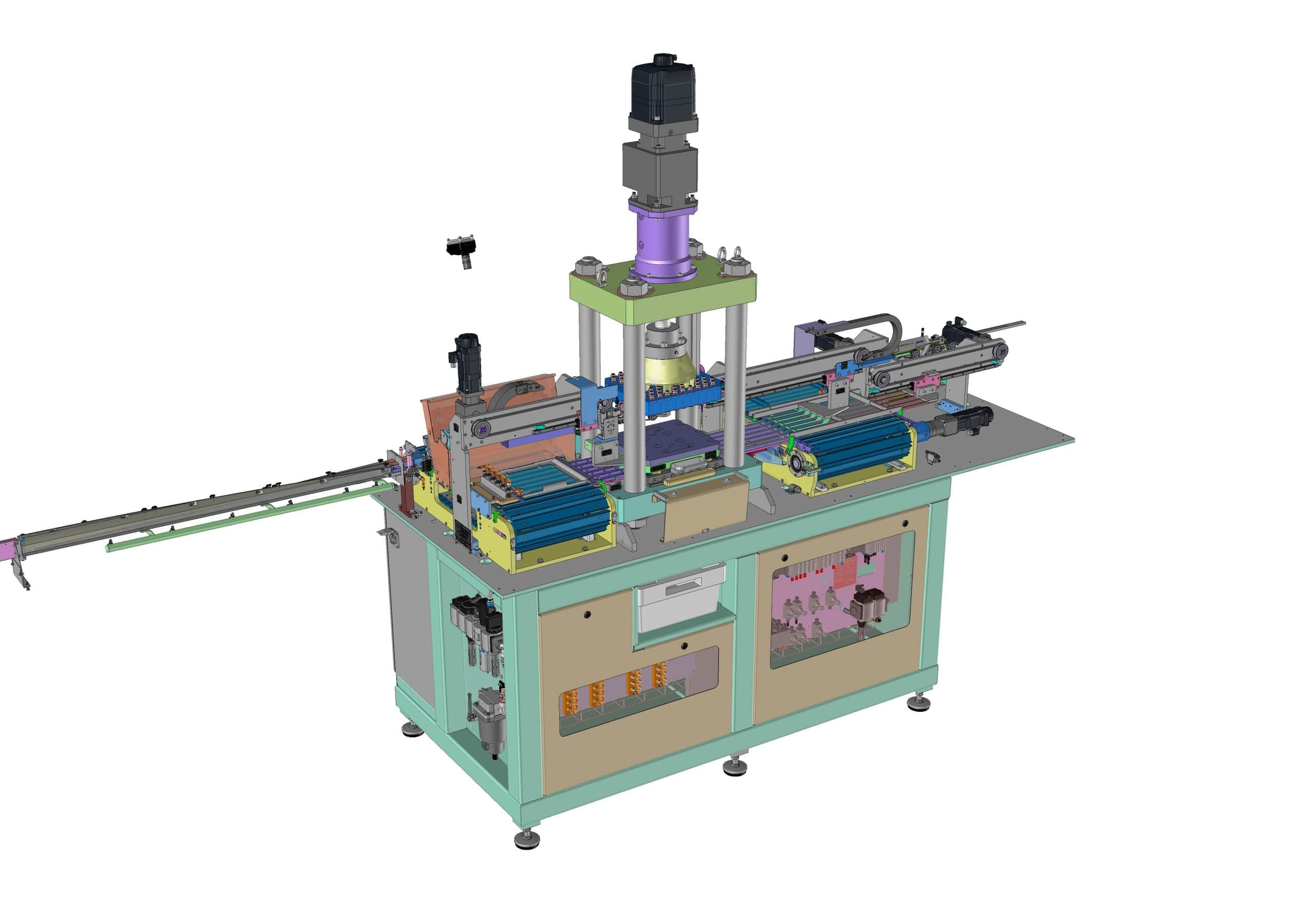

- CAD models, 3D animations, to make the preliminary project very explicit.

- Complete and detailed 3D CAD design and modeling

Study documents produced

- Detailed 3D equipment files (source or neutral)

- Complete bill of materials

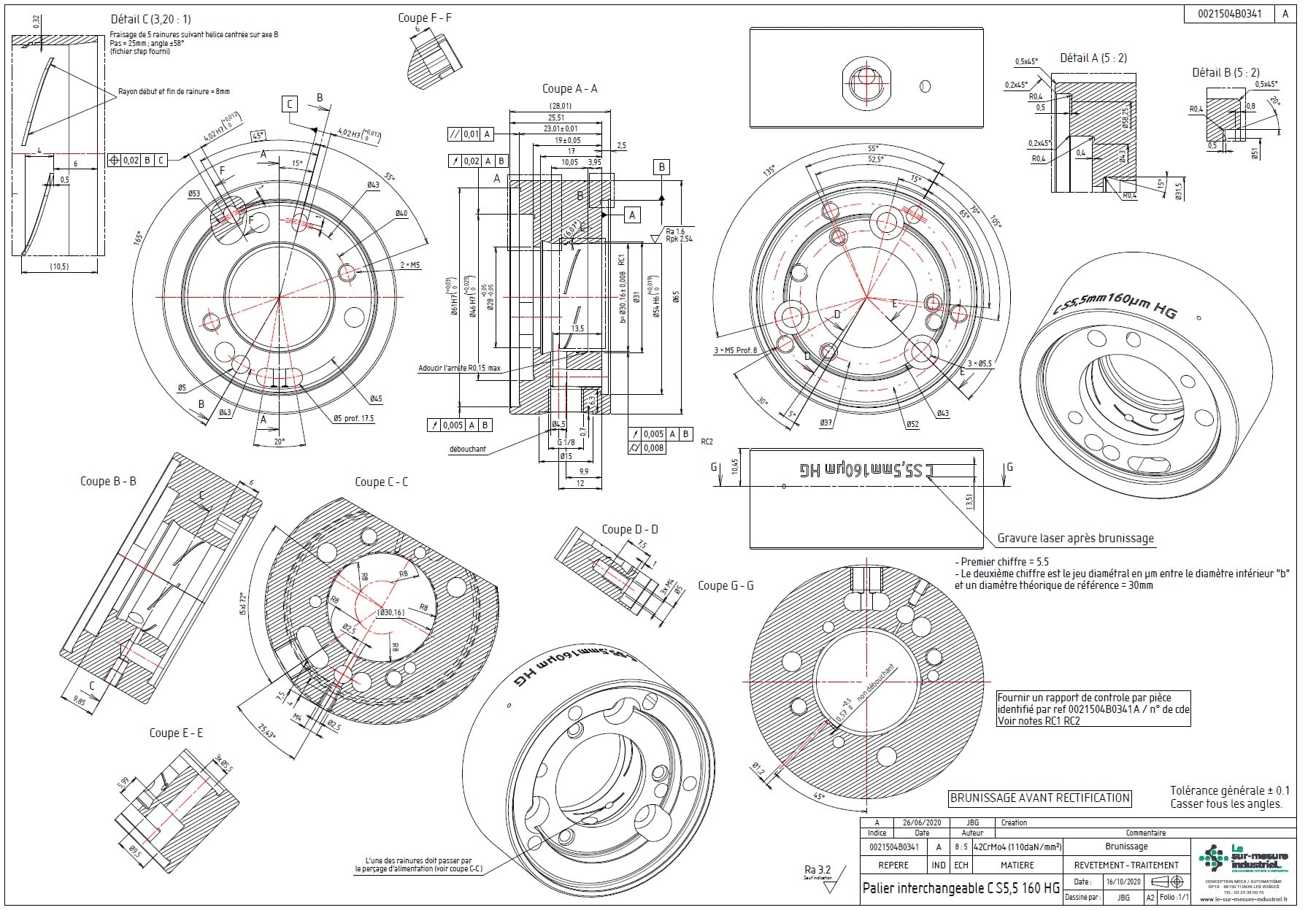

- Manufacturing and mechanical assembly drawings

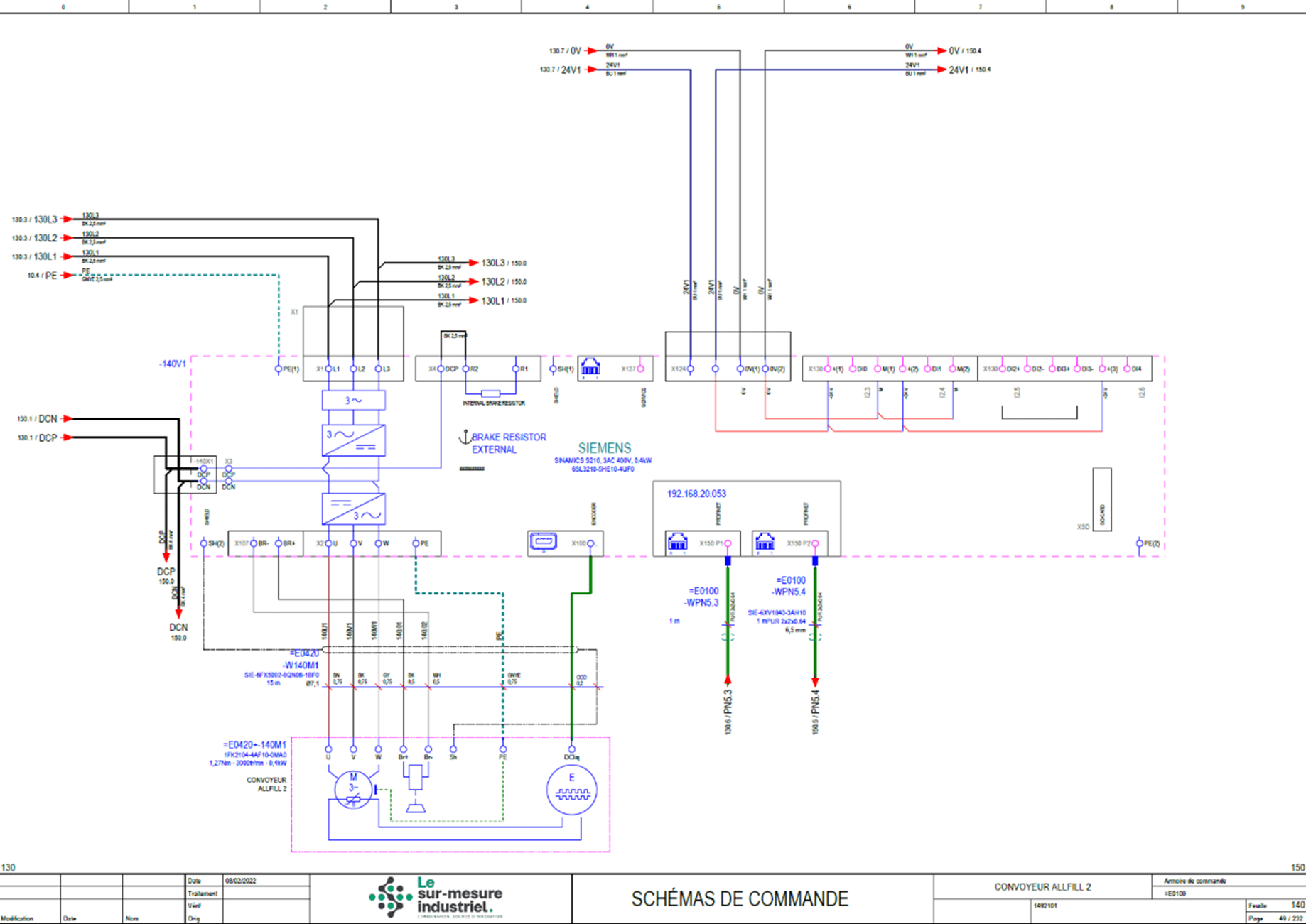

- Electrical and fluid diagrams

From the design phase we of course integrate the concepts:

- Workstation ergonomics

- Safety and compliance of machines in industry

- The specificities of manufacturing professions: machining, sheet metal work, foundry, cutting, injection, etc.

Benefits of these design steps:

- Clients and suppliers stay aligned throughout the project

- Validation of principles and clarification of choices

- Early resolution of uncertainties

- Production of precise documents for manufacturing

- Support for efficient and sustainable equipment maintenance

- Optimization of the overall project cost

A complete and accomplished mechanical design

The realization of your project begins with an engineering and study phase. During this phase we go through stages of calculations, digital simulation, prototyping, mechanical design, and electrotechnical feasibility.

Throughout the project, we discuss our progress and share our advice with you in order to make quality decisions while always adapting to your needs and your products. All this with the aim of establishing a healthy and lasting partnership between our companies.

During the CAD phase, we adopt a reflection on the production of parts for the manufacture of equipment. This development technique allows us to develop and produce a complete, high-quality instruction manual. Manufacturing-oriented design allows the optimization of the choice of materials and production processes (machining, molding, sheet metal, etc.) according to the functional needs of the parts (tolerances, geometries, cost).

A detailed electrical engineering study

Our design office adapts to your requirements in the choice of equipment or according to the constraints of your environment (food industry, ATEX, etc.). The electrical engineering study of the equipment results in obtaining an electrical diagram completed by a detailed bill of materials facilitating maintenance interventions. Depending on the applications, the provision of the pneumatic or hydraulic diagram is also an integral part of our design service.

Our team also works on the connectivity of your machine with your company’s network in order to be able to offer you traceability solutions or the edition of sensor measurement acquisition reports according to the applications.

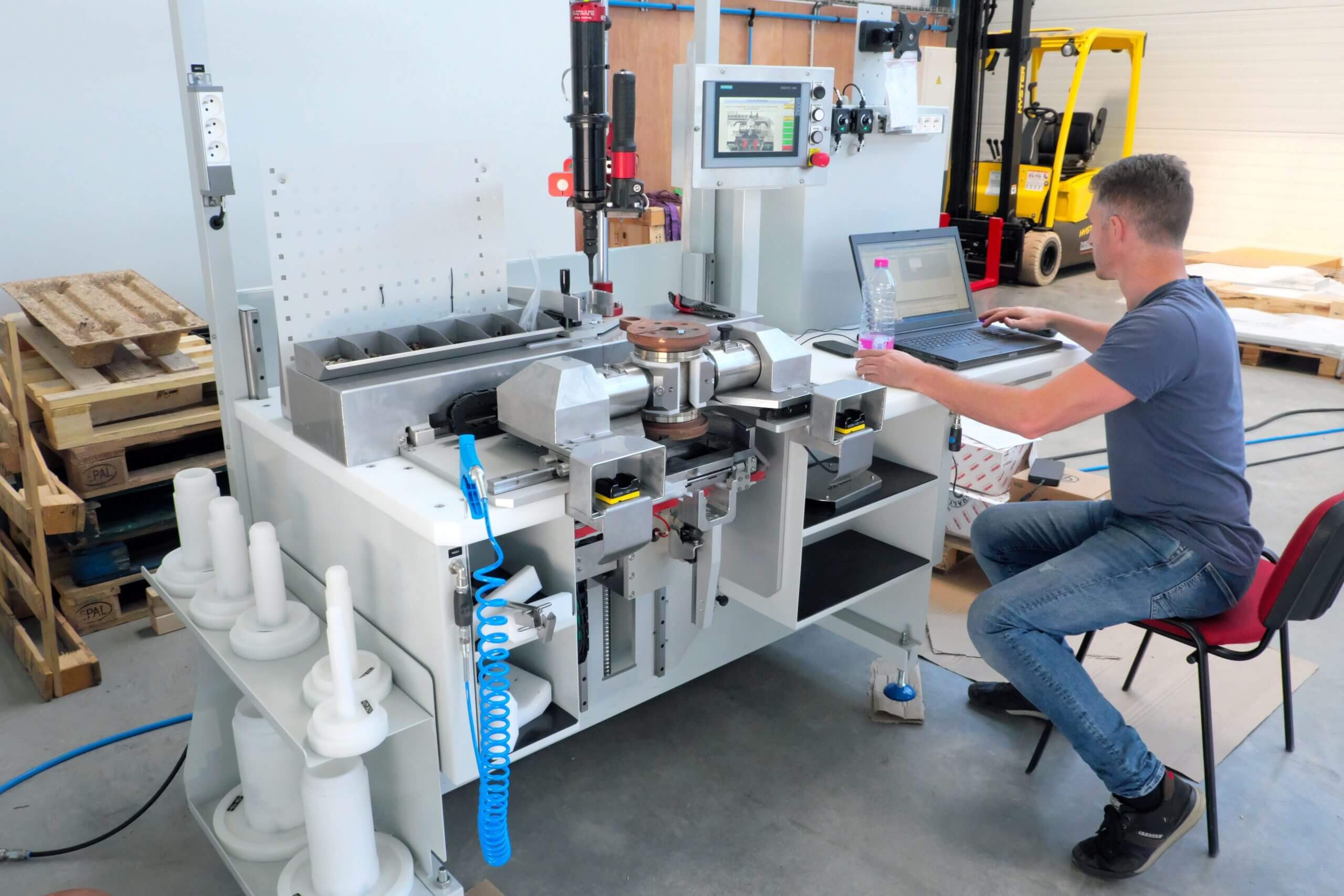

Quality automation

In parallel and in connection with mechanics, the development of automation within our company gives us overall control for the development of a system. This project management gives us flexibility for the implementation of solutions. It also allows us to offer our client companies a complete service during a program upgrade following the addition of new functions, for example.

We design sophisticated and complete HMIs with an intuitive and efficient display to facilitate the use of the equipment by the operator.

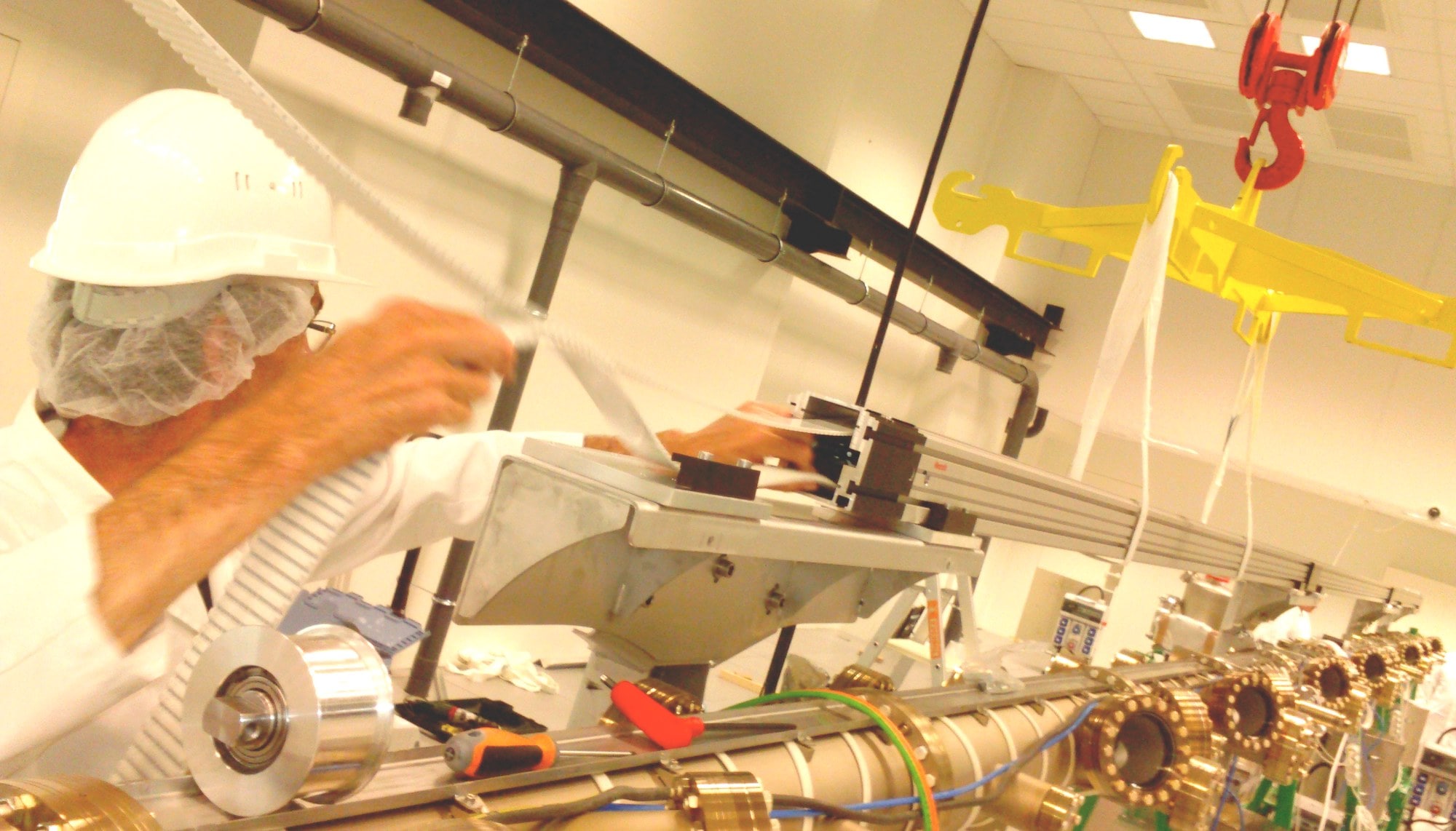

Assembly and fine-tuning

The project management of mechanical assembly within our company provides us with direct feedback on the technological choices made. This experience allows us to offer you today the solutions best suited to your needs.

Thanks to our local partners in machining and manufacturing parts, we have a quality responsiveness regarding the adjustment of parts or tolerances during production or development. We are part of a local industrial fabric with the majority of our suppliers having their companies located in France and Lorraine.

We ensure the wiring of our equipment. In order to validate the operation of the different equipment, and to make adjustments, we test the program and the PLC. This machine development phase is an opportunity to react quickly to the various necessary modifications.

Commissioning in a company

The packaging and shipping managed by us allow the loading and transport of equipment while preserving its integrity. We are able to ship small tools and machines weighing several tons in France and internationally.

All of our equipment are CE certified and can obtain the expertise of an external consultancy firm if you wish.

In order to ensure the mechanical installation and the commissioning of the equipment, we intervene directly on your premises, with your products and your personnel.

Quality support and assistance

The reliable mechanics and rigorous automation that characterize our equipment are a guarantee of performance for our customers, who have been using our machines for over 30 years.

In all our projects, which have been completed in over 150 companies, our in-house maintenance and machine operation departments are very often autonomous. They rely on the comprehensive technical files and manuals we supply.

If necessary, they can also count on our responsiveness to assist and troubleshoot: supply and replacement of parts, instructions or information on use, remote control….