Prototyping

Interested in prototyping?

Our company provides you with a direct solution, from design to commissioning.

When it comes to implementation, we look for subcontractors capable of meeting your needs. You have a single point of contact, no matter how complex the project.

We retain control of the project so that it runs smoothly until our customers are satisfied.

From design to manufacture

Your core business must remain at the centre of your concerns. Based on your objectives and the phases of the project defined together, we design your prototype so that it provides the answers to your needs.

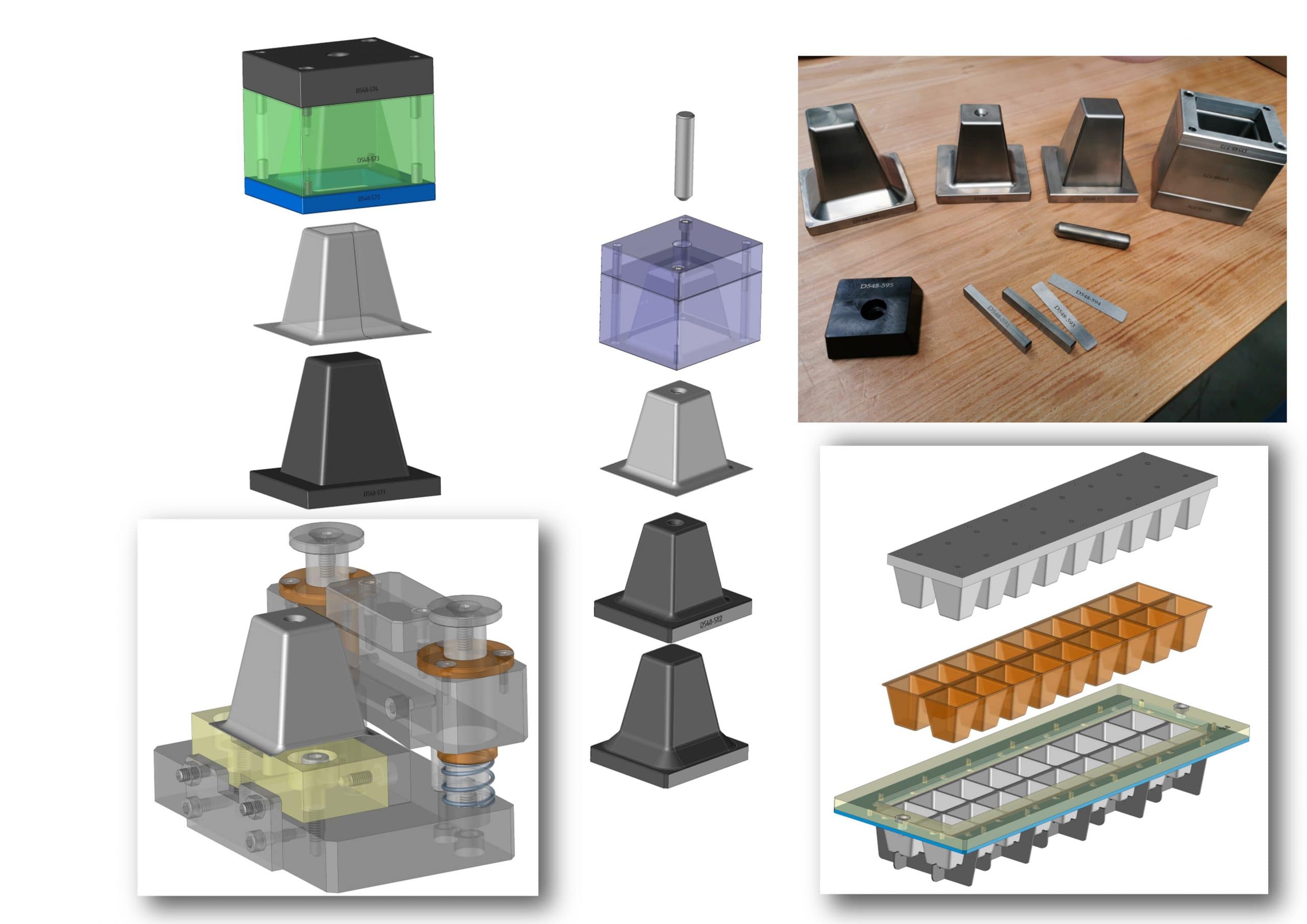

It all starts with the design phase, during which our engineers and technicians design around your needs. We identify the best test concept and the most appropriate manufacturing technique and tools. We choose the processes to be used, such as conventional machining, mechanised welding, injection moulding or even additive plastic manufacturing.

Our local suppliers and partners in the north-east of France have the skills and tools to meet our cost, lead-time and quality requirements.

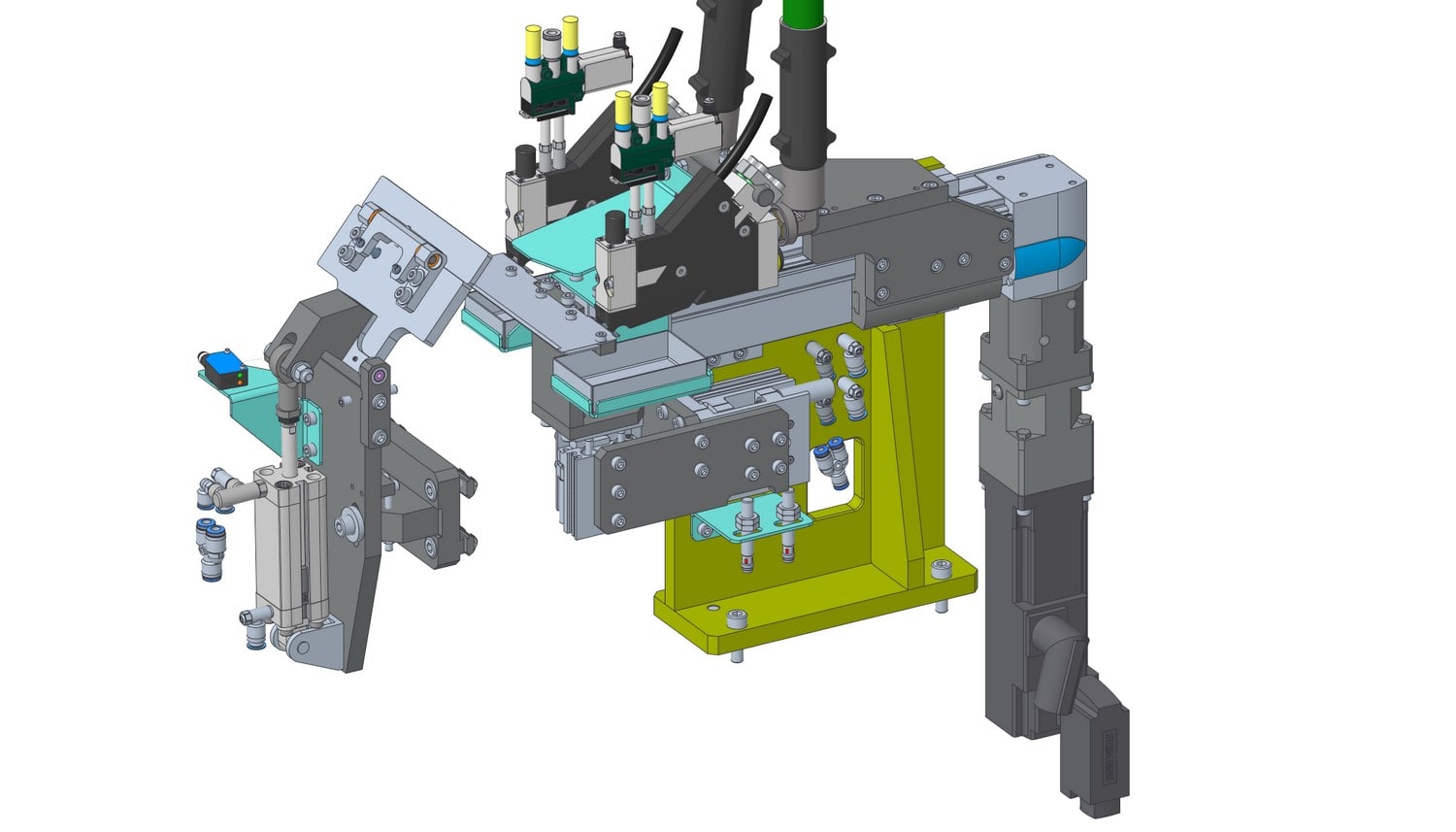

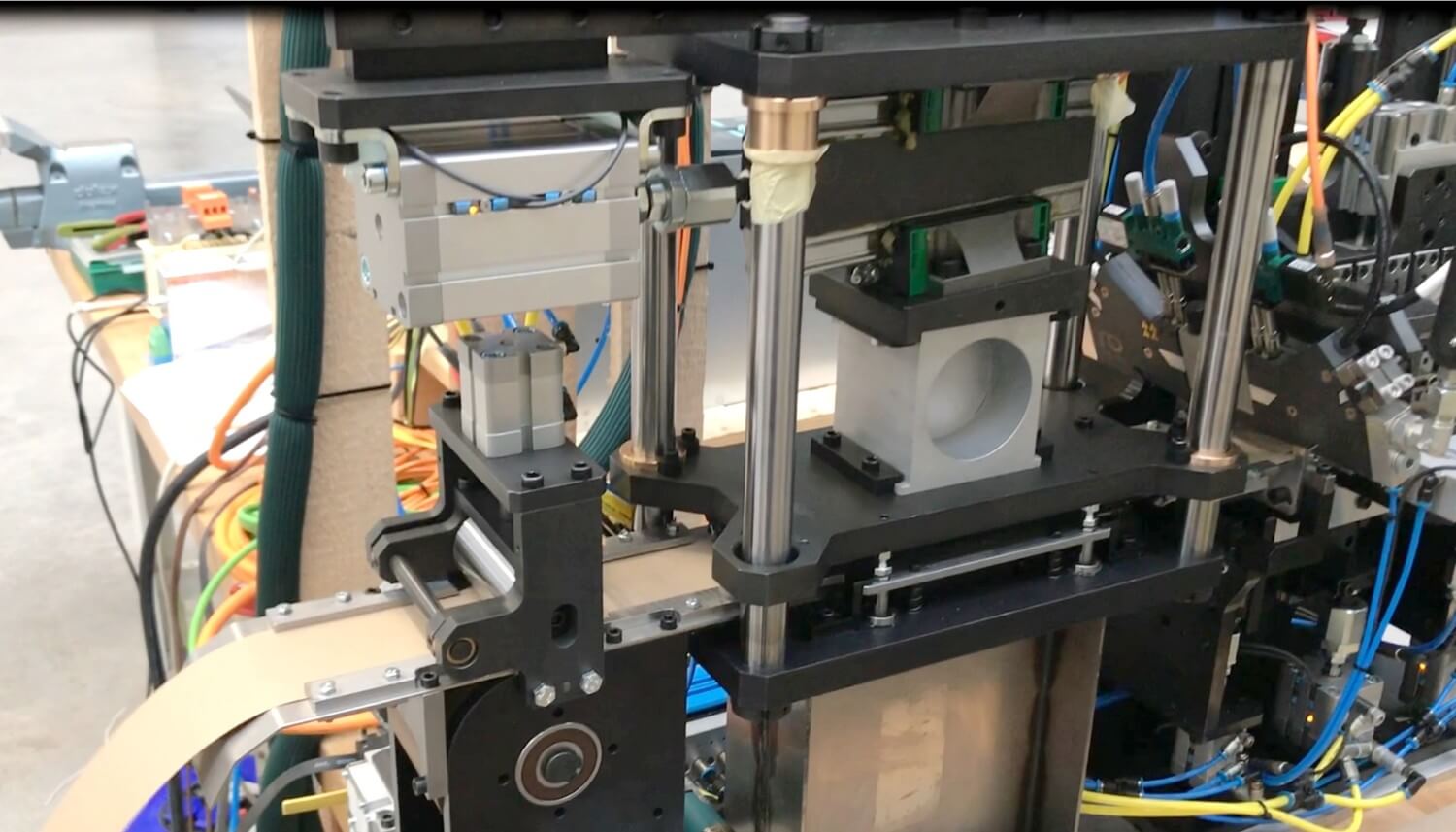

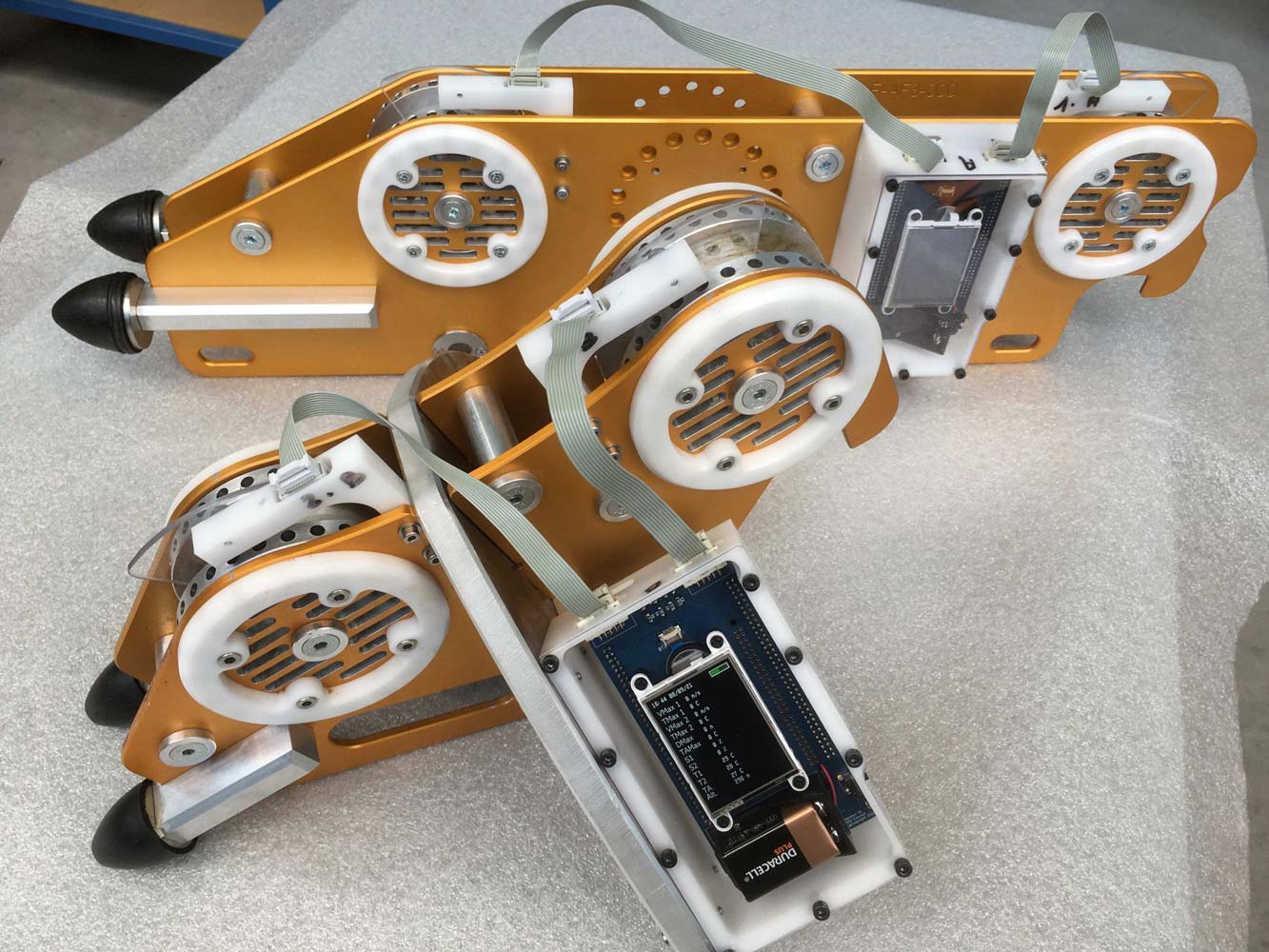

Some examples of prototypes

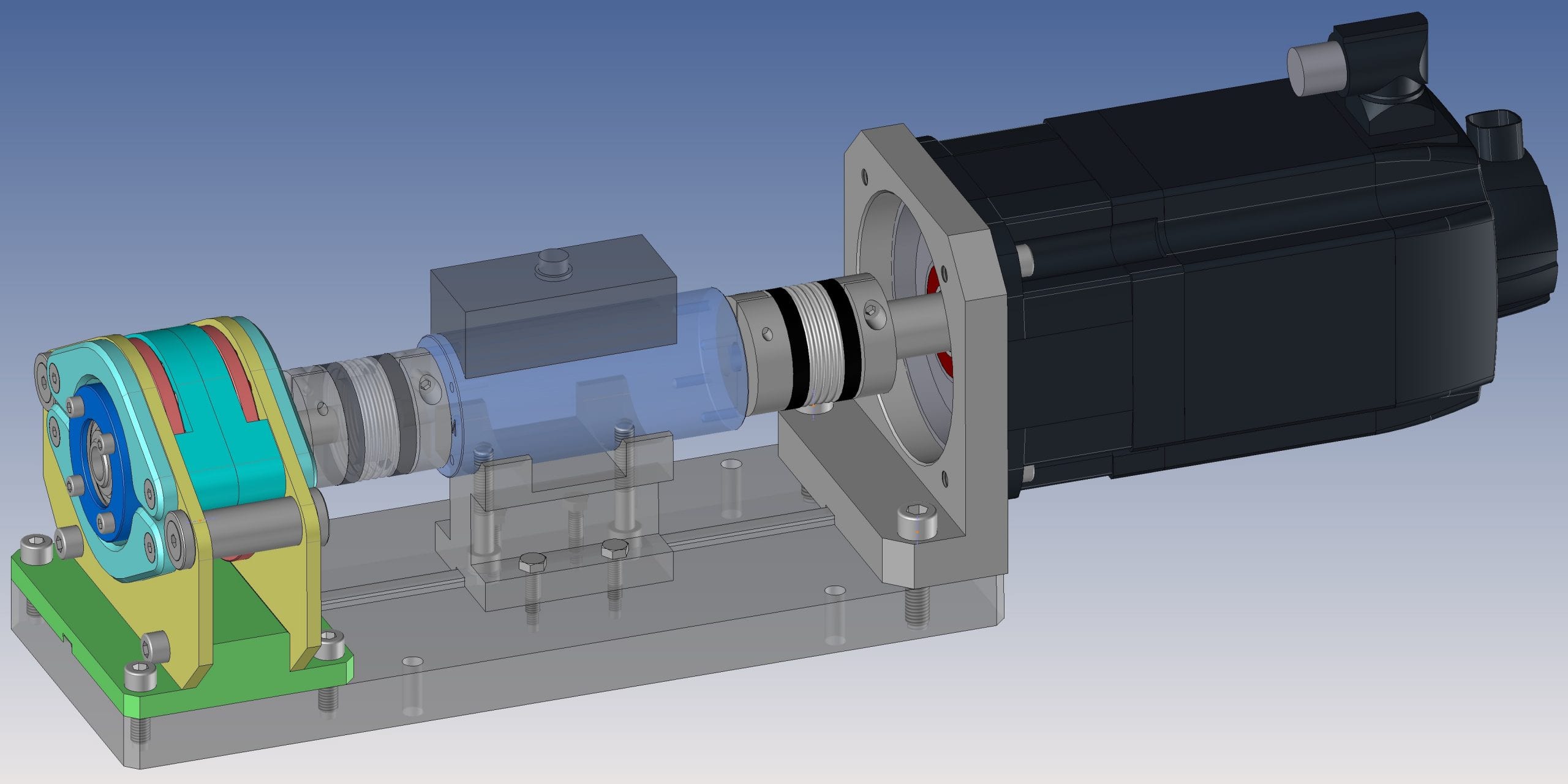

- Design, production and performance testing of carbon bearings in high-speed rotating machinery

- Machine for validating vision control on ophthalmic lenses

- Burst testing of medical bags

- Zip line test trolleys to validate a new innovation

- Complete cardboard shaping sub-assembly

- Automatic zip-line cable de-icer: design, testing, improvement

- Bottle positioning in the packaging industry

From the simplest prototype to the most elaborate

We design prototypes that may be purely mechanical, as part of tooling or production tools, or else instrumented with sensors that allow the signals of the physical quantities to be measured to be recovered.

The collection of data is important in the validation of the products to be tested: temperature, pressure, loads exerted on the parts, speed of rotation, or any other physical data.

Where necessary, we can develop data acquisition systems, using LabView, for example, to process data quickly, or create calculation routines using Matlab. In some cases, a specific licence is required at the start of the project if a particular development language is requested by the customer.

We can also integrate automation at any stage of the project if required. The aim of all this is to gather as much data as possible at the prototype stage so that there are no surprises to delay the project and the production of the final product.

When the products to be tested allow it, the use of rapid prototyping such as plastic-based 3D printing is used, facilitating the development of complex parts at lower cost and with a rapid turnaround time.

Prototyping for all sectors of activity

We create prototypes for our customers in the automotive, aerospace, biomedical, steel, mechanical engineering and leisure sectors, which they can use to ensure that the final design meets their functional requirements with as few iterations as possible.

During this prototype development phase, we ensure that all the ideas are put on the table, using brainstorming and design thinking techniques to facilitate the creation of the product. We anticipate its eventual industrialisation so that the final product satisfies all users.

The best manufacturing techniques and practices are studied with our suppliers to minimise material and energy costs. The parts development process can lead quickly to the prototyping phase, so that we can react quickly to change all or some of the components. Our close relationships with local suppliers give us the kind of agility that a large company cannot offer. This is essential if we are to investigate innovative production processes. It is also during this prototyping phase that we can test the influence of a part’s finish or surface condition, for example, with the aim of finding the best compromise between technological level, cost and quality.

The benefits of prototyping

Do you want to explore an unfamiliar design, develop a product or parts, or validate a manufacturing process and procedures? Have you developed a design and would like to subcontract the production of a prototype to ensure that it meets the required functions?

Le Sur-Mesure Industriel is at your side to meet your validation needs, allowing you to concentrate on your core business. We can help you through the various stages of design and conception, using our 3D tools to produce prototypes to validate your project. We can then work with a wide range of local subcontractors to create your mock-up as quickly as possible. We don’t hesitate to explore innovative techniques such as 3D printing where appropriate.

We can also help you carry out tests and measure physical quantities, and then help you interpret the test results.

You don’t have the in-house flexibility to quickly carry out functional tests to validate a design choice? Does your company want to test the use of different materials, designs and manufacturing techniques, and would you like a design office to help you produce a mock-up?

Are you looking to validate your parts quickly and cost-effectively before putting them into production? Do you lack the necessary resources and are you looking for a partner to carry out these principle tests?

Frequently asked questions about our prototyping services

When is it worth making a prototype?

How can you benefit from effective prototyping?

Who should I entrust with the design of my prototype?

Le Sur-Mesure Industriel has all the skills and experience to support you in this field.

You'll have a single point of contact for the design, production and operation of your prototypes: mechanical engineering, automation, test management and use of the results.

What techniques are used for prototyping?

Depending on the objective, different prototyping techniques can be used. The aim is to test parts at the lowest possible cost. For example, 3D printing is a good alternative to moulding or injection moulding, as it avoids the need for expensive moulds before the geometry of the parts can be validated in detail.

As a general rule, prototypes are made to best represent the characteristics of the final assembly imagined.

What is the difference between prototypes and industrialised assemblies?

Prototypes often use measurement sensors that will no longer be needed in the final equipment.

Finishing touches or cosmetic parts are generally saved during the prototyping phases.