Research & Development

What type of research are we talking about?

Research and development covers all the activities carried out by a company to increase its knowledge potential, often with the aim of developing new applications. Le Sur-Mesure Industriel, based in the Vosges region of France, focuses on applied and experimental research.

We exclude all fundamental research, which is closer to the skills and interests of laboratories (which we can, however, support in the development of test equipment, for example). For us, each field studied is linked to the practical and concrete application of an innovation, in the service of the function sought by the requesting companies.

Supporting companies in R&D

- Does your company want to launch an innovation project in France or abroad and are you looking for support?

- Do you have an idea for an innovative concept but don’t have the time or resources to develop the solution on an experimental basis?

- Do you want to achieve a specific function but don’t know what technological solution to implement, or does the solution not yet exist?

Our company's expertise for your R&D projects:

- Development of industrial production and control equipment.

- Development of customised equipment

- Design and manufacture of special machines

- Various fields of application.

- Automation of industrial processes

- Improvement of production processes

- Product development and industrialisation

Research and innovation

Our team in France very often works on innovative subjects to find original designs that meet a precise need, especially when the solution does not yet exist.

We can also help you put together an application for research tax credit funding, providing calculation notes and precisely documented technical elements so that your company can build a solid case.

Le Sur-Mesure Industriel is based in Thaon les Vosges, France, and offers R&D, test facility design and prototyping services.

By combining these 3 complementary aspects of engineering, our company specialises in developing solutions for businesses, helping you to bring your projects to fruition. We have a highly experienced team capable of tackling a wide range of technical and scientific subjects.

The means implemented

- Feasibility and process studies

- Calculations

- Literature analysis

- Analysis of patents

- Presentation of animated CAD models

- Tests in partnership with laboratories at neighbouring universities (Epinal, Nancy) and technology transfer centres (CRITT)

- Numerical simulations, in partnership with design offices specialising in finite element calculations.

R&D objectives for companies

Defining the specifications

To help you define and write your specifications. Very often, your needs themselves are not entirely clear, because there are so many variables to take into account that it’s difficult to define a clear set of specifications. Through a process of R&D, we will work with you to refine the avenues of research that will help you see things more clearly, eliminating paths that serve no purpose so that you can concentrate on the essentials.

Define a production or transformation process

Joint process research between your engineering departments and ours, to combine your company’s skills and know-how with our R&D department. You are the one who controls the expectations and requirements of your products, and sometimes it’s necessary to investigate different manufacturing processes with us. We can help you broaden the scope of what’s possible by looking for process innovations.

Take advantage of our outside view, our expertise and our objective analysis by contacting us by email or telephone.

Solve a problem, looking for technical solutions

A major objective of R&D is also to facilitate the operation of your products and services, increase the reliability of systems and reduce costs. Once the initial design and commissioning are complete, companies very often seek to optimize the function. After a given operating time, the feedback on improvements takes on its full meaning, and it is also at this point in the life of a product or process that R&D intervenes for its optimization.

Call on our company for your improvement and optimization projects.

Examples of some projects involving research and development (R&D)

Gas/liquid refrigerant operated system

Pressurized air bearing

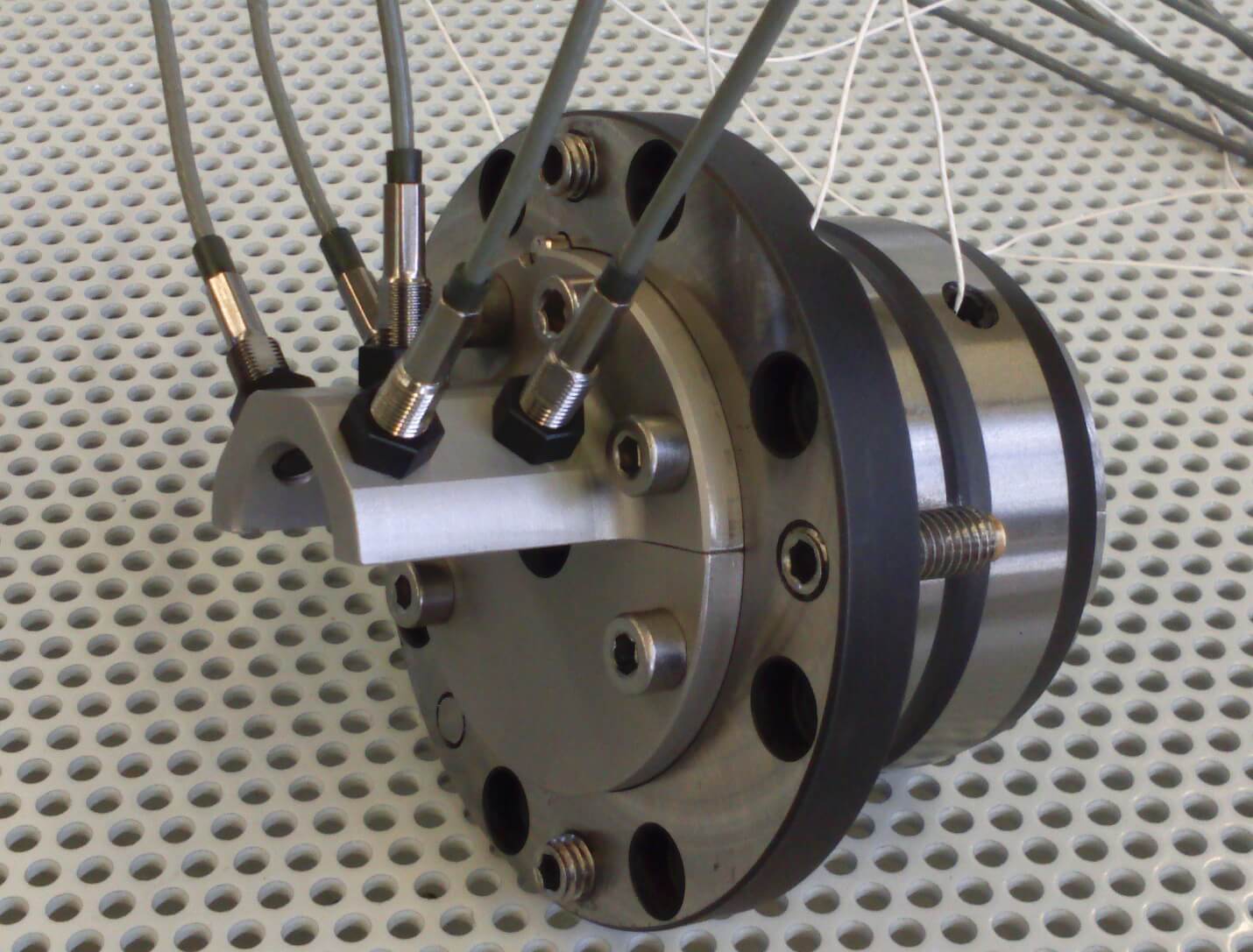

Linear and rotary guidance systems with ball bearings and bushings, even precision ones, have operating clearances or rolling resistances that can sometimes be too high. Our R&D engineer has worked on creating bearings with impressive load capacities, while maintaining almost zero friction.

This concept is an improvement on a conventional air bearing, replacing the air holes with a porous material.

This has many advantages: having a homogeneous distribution of air on the contact surface, very low air consumption and therefore economical, much higher load-bearing capacity in a reduced footprint. Research work was carried out to test which porous material meets the constraints of the specifications of our customer's application. The practical application of this system concerns a very precise torque measuring machine, supporting significant radial and axial loads.

Are you interested in this principle? Contact us to discuss possible applications for your company.

Magnetic braking

In the leisure sector, manufacturers of large zip lines are looking for new descent routes in increasingly steep mountainous areas. It is necessary to design autonomous braking systems that prevent the passenger from gaining too much speed. We have developed a system whose braking power is a function of speed thanks to magnetism. This innovation allows users to arrive at the braking station at the right speed and the operator to have a contactless and therefore wear-free retarder system. For this innovation, we have even developed an experimental test bench internally that replicates the rotation speed of a trolley roller and allows us to test several braking configurations by measuring their effectiveness.

We also measured the temperature rise to determine the right product design for efficient cooling. This is ensured by forced ventilation, taking advantage of the natural descent speed of the trolley and thanks to a ventilated disc validated on this test means (See our “testbed” section).

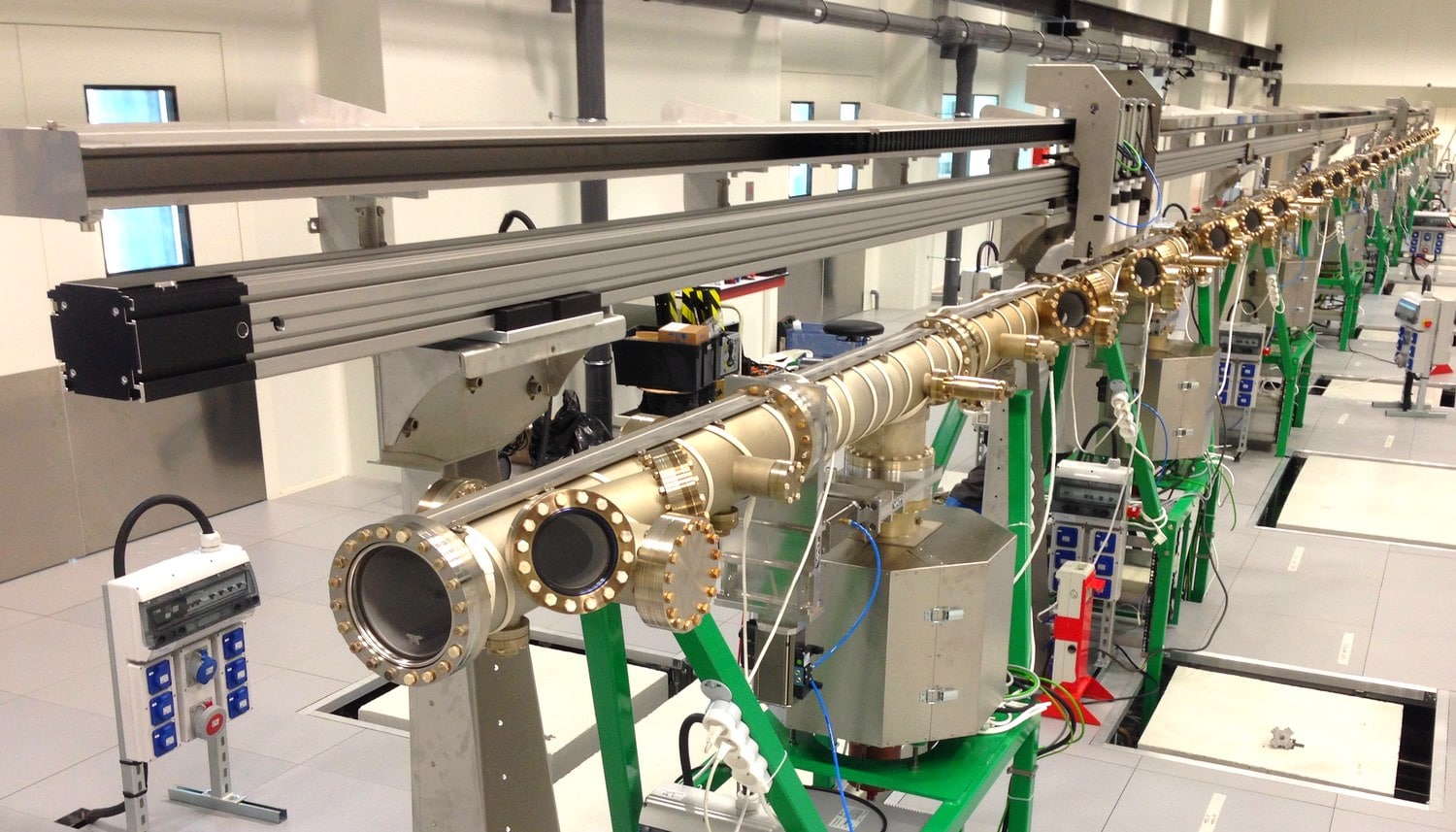

Contactless movement and communication

A contactless communication between the inside and the outside of the tube was specially invented in co-contracting with one of our partners specialized in the field of electronics.

Burst enclosure and sound insulation

In this application, we studied the design of an enclosure in which a burst test is carried out. The tested products must withstand a certain pressure. Tests up to bursting are therefore carried out very frequently to qualify the products.

In this project, we optimized the acoustics of the enclosure by adapting a decompression chamber principle used in firearm silencers. The objective is to ensure that an operator can work nearby in complete safety, with comfortable noise levels.

If you have applications that can use this acoustic enclosure development, please send us your specifications by email.

High pressure water jet pump

The process research allowed to develop this custom equipment.

Progressive braking system

The development project made it possible to provide a comfortable technical solution for the passenger while adapting to the weight and speed of the descender to maintain the same efficiency.

The principle developed is the subject of a patent, filed by the company that entrusted us with the studies, concerning the progressiveness in braking, allowing rapid arrival speeds with high slowing down efficiency and improved comfort for the user.

Process improvement

Do not hesitate to tell us about your projects and entrust us with your studies.