Special machinery / Tools

Design and manufacture of machines to customized specifications

In all sectors of industry, if you’re looking for a machine, a checking fixture or customised tooling that needs to be imagined and created : Contact us!

Le Sur-Mesure Industriel can help you in the Grand-Est region, throughout France and even abroad. We are based in the Vosges and specialise in the development, design and manufacture of custom-made equipment, specifically adapted to your needs.

If you’re looking to develop or design equipment specifically customised to your needs, you can call on us. We work in a wide range of sectors, mainly in industry: food, wood, paper, plastics, mechanical engineering, medical, electrical engineering, leisure and many others…

We manage projects from A to Z, from design to commissioning.

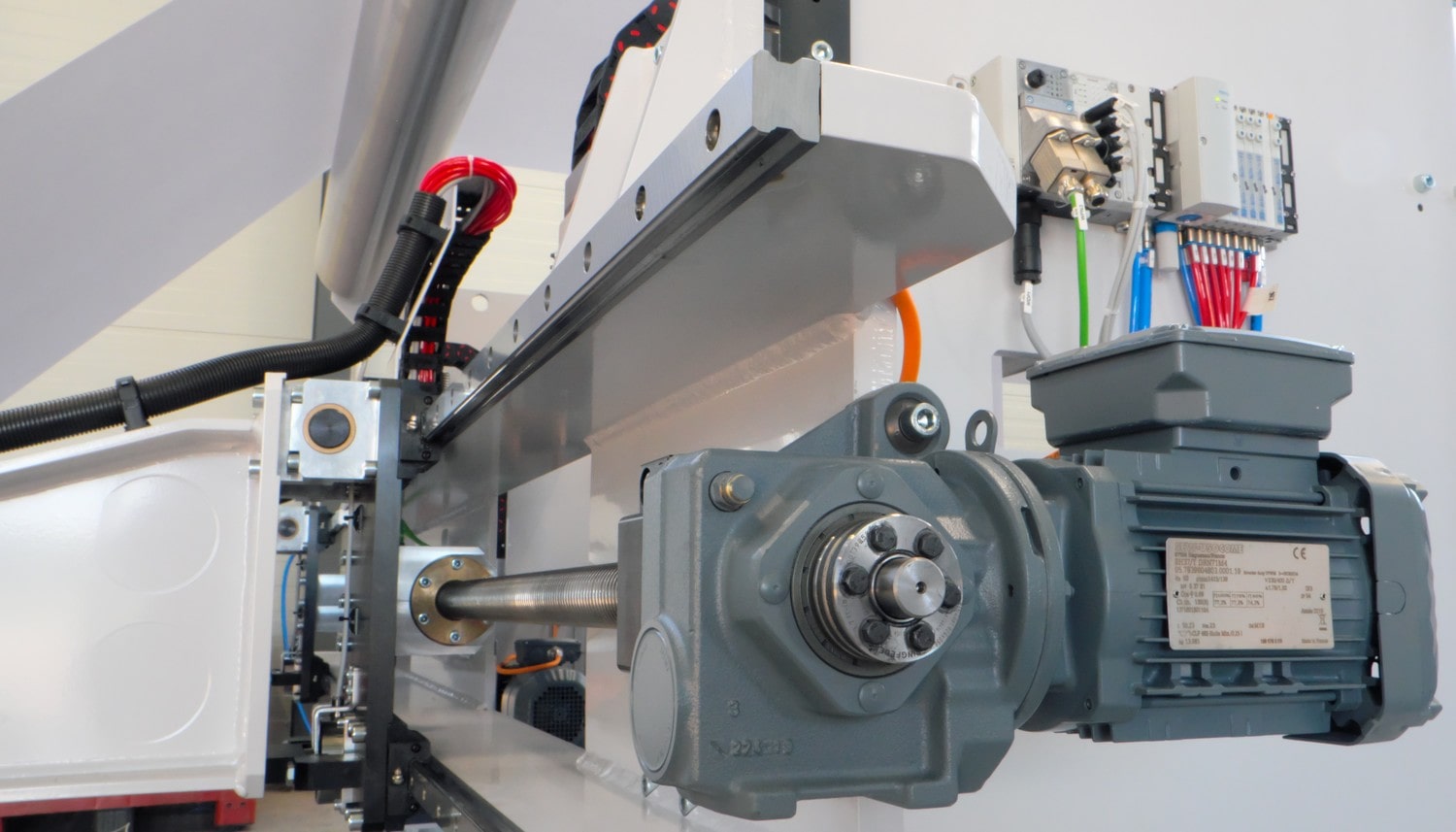

Versatile manufacturer: mechanics, automation, robotics, machine vision

In our company, the team at your service has a rich and varied range of skills. When it comes to designing and building a piece of equipment or a production line, our engineers and technicians deal with mechanical engineering and industrial automation. They also integrate and program robots and develop machine vision functions. Find out more about our industrial engineering services.

With us, the link between all these disciplines is permanent, from feasibility to commissioning! This represents a considerable advantage in terms of efficiency and consistency.

Any exemples?

Here are a few examples of solutions we have developed:

- Manufacture of machines or product assembly lines (crimping, gluing, screwing, welding, etc.)

- Various processing equipment (pressing, folding, cutting, machining, grinding, marking, etc.)

- Cutting machines for various products (paper, plastic, metal, wood, etc.)

- Packaging lines

- Laser marking

- Integration and programming of industrial robots

- Developments in machine vision, camera control and image analysis

- Design and production of instrumented testbeds

- Inspection and testing equipment (geometry, strength, tightness, continuity, etc.)

- Automation of manual operations or tasks

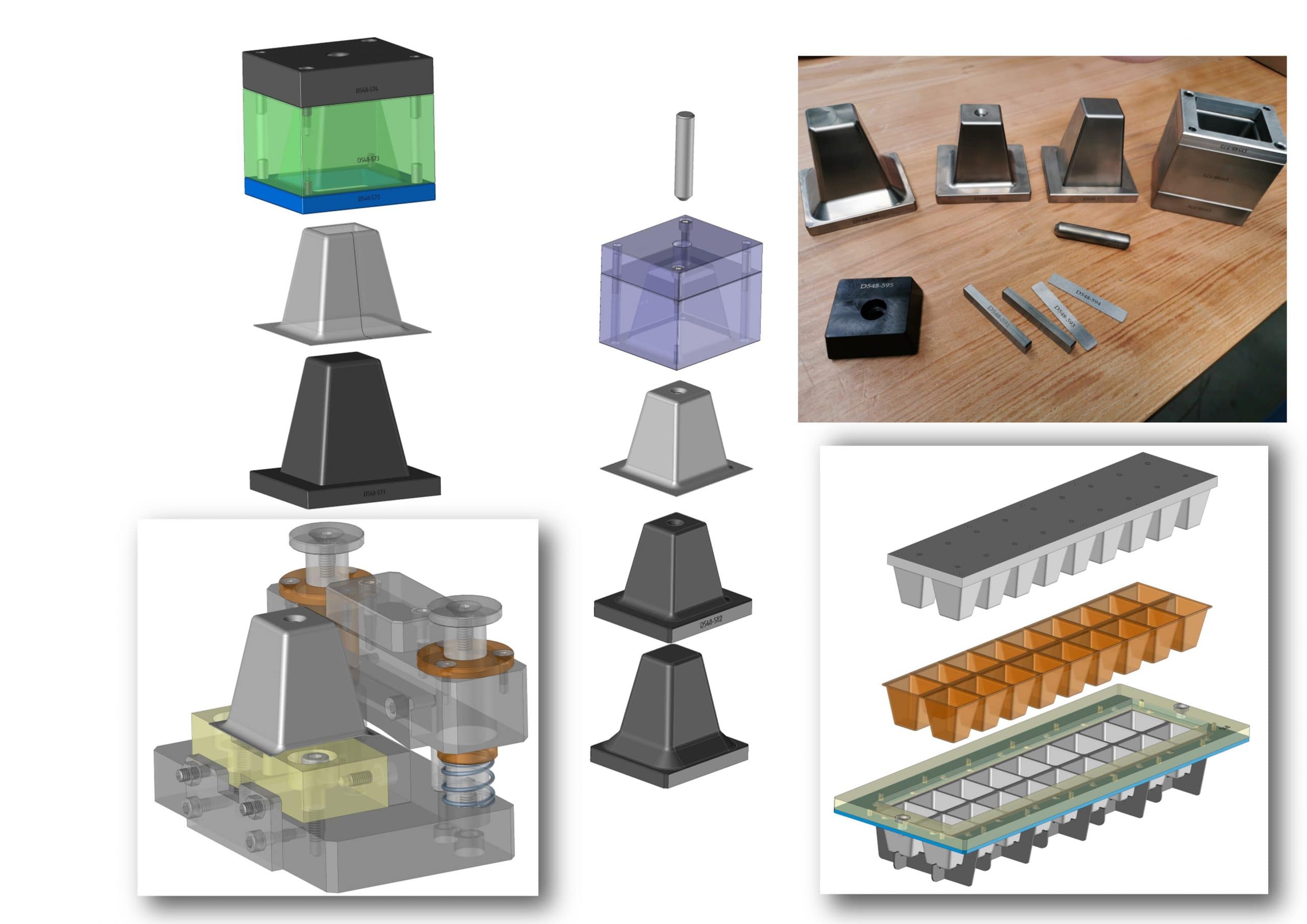

Tools

- Creation of lifting and handling tools

- Assembly tools

- Inspection tools (vision, flow, geometry, fatigue, etc.)

- Welding and dimensional control jigs

- Maintenance equipment for press tools, site machinery and industrial installations

Le Sur-Mesure Industriel, special machinery manufacturer

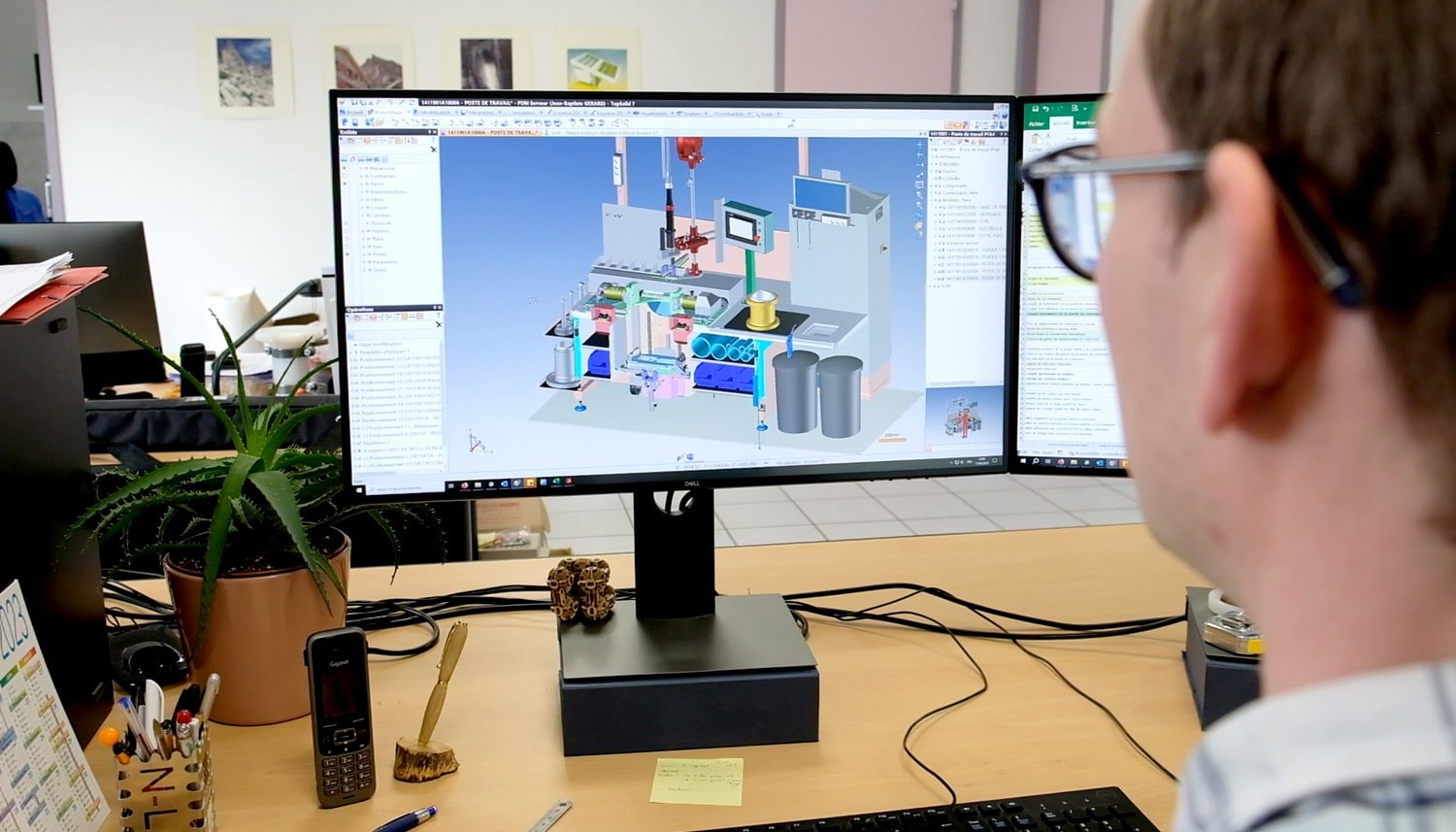

Study and design

When the solution is not obvious, we can be a force to be reckoned with. Thanks to our experience in a wide range of industrial sectors, we can come up with innovative concepts to solve the problem. Our design office then takes charge of the mechanical design, using detailed 3D CAD.

Working in close collaboration, our automation specialists carry out the electrical and pneumatic design of the future machine, defining and selecting the equipment required and producing the diagrams and bills of materials.

Find out more about our engineering and design services

Manufacture, assembly and fine-tuning of equipment

Thanks to our suppliers, who are specialists in their field of manufacture, we can have the parts we design produced. There are no limits to our imagination when it comes to designing parts: sheet metal work, mechanical welding, precision machining, electro-erosion, moulding, or any other process depending on the functional requirements of the parts and the economic objectives of the project. At the same time as manufacturing, we also supply the commercial components that we have selected and sized.

We then assemble the machines in our assembly hall, next to the design office. Then comes the electrical wiring and programming of the automated or robotised operations. These last tasks are carried out by our automation specialists.

Find out more about the different stages of production

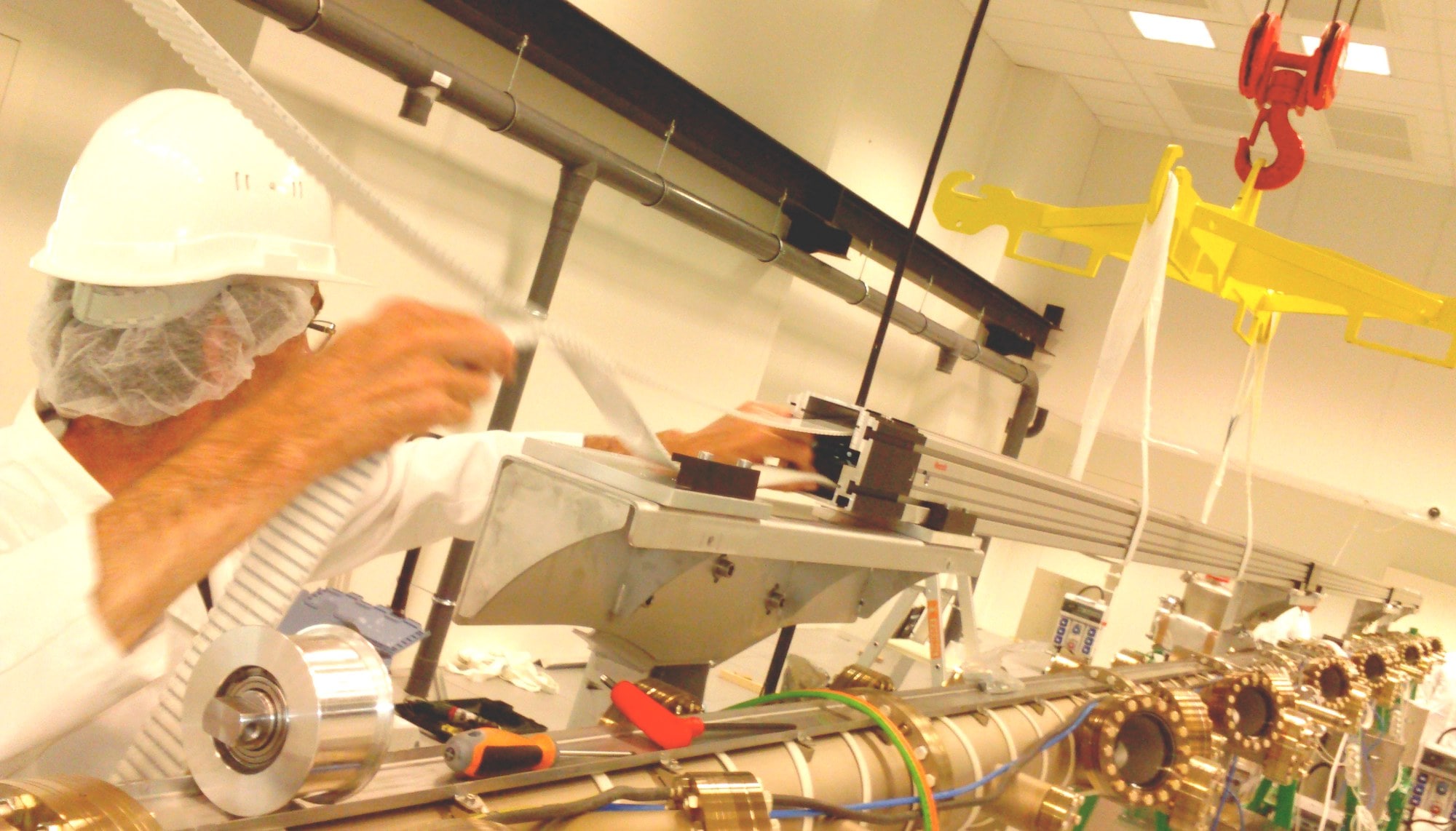

Installation, on-site commissioning, support

Finally, we visit our customers’ sites to install and commission the equipment. At this stage, we fine-tune the settings under actual production conditions. We also provide training for the people using the equipment: production, maintenance, quality, etc.

On delivery of a piece of equipment, our customers receive a complete technical documentation with all the design documents: exhaustive parts and components lists, assembly and exploded drawings, electrical diagrams, CAD files, source programmes, instruction manual, list of spare parts, preventive maintenance operations.

As after-sales service, we are also happy to respond to any request for support or assistance following commissioning, for all our industrial equipment that has been in operation for 32 years, in France and abroad!nger !

Frequently asked questions about our special machines and tooling

What is a special machine?

A special machine is a machine designed specifically for a given application. The difference with ‘standard’ equipment is major, because special machines are developed and manufactured to meet your needs, taking into account all the constraints specific to your activity, your application and your products.

This can apply to any industrial process: production, manufacturing, transformation, assembly, handling, inspection, packaging, marking, etc.

How can I find a manufacturer who can meet my specific needs?

If you're looking for a manufacturer of custom-made technical solutions in France, to design and manufacture your special machines and tools, contact us.

We can adapt to a wide range of professional sectors.